nov . 06, 2024 07:15 Back to list

Leading Manufacturer of Welded Gabion Mesh Solutions for Versatile Applications

The Rise of Welded Gabion Mesh Manufacturing

In recent years, the construction and landscaping industries have increasingly turned to innovative materials that offer durability and versatility. One such innovation is welded gabion mesh. This versatile construction element has gained prominence due to its strength and adaptability in various applications, ranging from retaining walls to decorative landscaping features. As a leading manufacturer of welded gabion mesh, understanding the production process, applications, and benefits can provide valuable insights into this growing market.

Understanding Welded Gabion Mesh

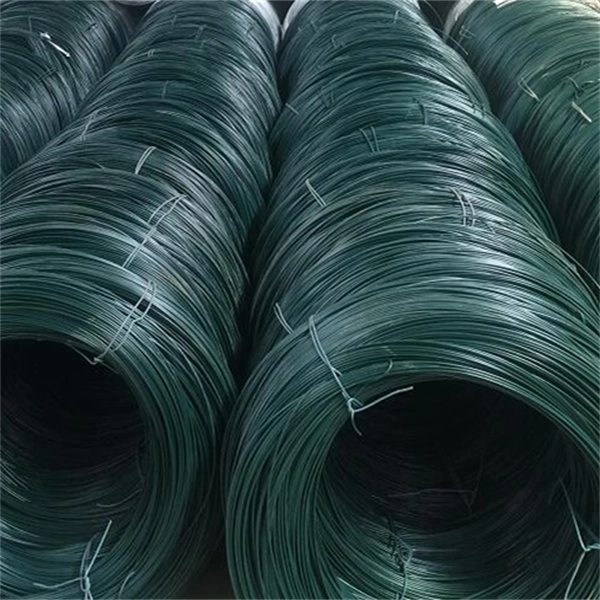

Welded gabion mesh is made from high-quality steel wire that is welded together in a grid pattern, creating a robust mesh structure. This welded design provides superior strength and stability compared to traditional woven mesh, making it an ideal choice for a variety of construction applications. The wires are usually coated with materials such as zinc or PVC to enhance their corrosion resistance, thereby extending the lifespan of the gabion structures.

Advantages of Welded Gabion Mesh

1. Strength and Durability The welded design offers higher tensile strength, allowing it to withstand the stresses of soil and water pressure. This makes it suitable for use in environments where traditional materials may fail.

2. Easy Installation Welded gabion mesh units are simpler to assemble than their woven counterparts. They can be pre-fabricated and easily transported to the site, resulting in reduced labor costs and shorter installation times.

3. Environmental Benefits Gabion structures can be filled with natural materials such as stones, gravel, or soil, which blend seamlessly into the environment. This makes them an environmentally friendly option for erosion control and landscaping.

4. Versatility From retaining walls to riverbank protection, the applications of welded gabion mesh are virtually limitless. Their ability to adapt to various design specifications makes them a go-to choice for architects and engineers alike.

5. Cost-Effectiveness While the initial investment might be slightly higher compared to other materials, the long-term benefits of welded gabion mesh, such as low maintenance and durability, make it a cost-effective solution.

welded gabion mesh manufacturer

Applications of Welded Gabion Mesh

Welded gabion mesh is widely utilized in several applications, including

- Retaining Walls They provide a robust, long-lasting solution for vertical earth retention, preventing soil erosion and providing structural stability.

- Riverbank Protection The mesh can be filled with stones to create barriers that protect riverbanks from erosion due to high water flow and tidal actions.

- Landscaping Welded gabion baskets can be used creatively in landscaping for decorative walls, seating areas, and garden features, enhancing the aesthetic appeal of outdoor spaces.

- Sound Barriers In urban areas, welded gabion structures filled with stones can serve as effective noise barriers, reducing road noise near residential areas.

The Future of Welded Gabion Mesh Manufacturing

As construction practices evolve to prioritize sustainability and efficiency, the demand for welded gabion mesh is expected to grow. Manufacturers are also exploring advanced materials and techniques, such as high-strength alloys and environmentally friendly coatings, to improve the performance and lifespan of gabion products.

In conclusion, welded gabion mesh represents a significant advancement in construction materials. With its strength, adaptability, and environmental benefits, it provides a practical solution for a multitude of applications. As a manufacturer in this field, investing in quality materials and innovation will not only contribute to the success of your business but also align with the growing demand for sustainable construction practices. Emphasizing these key aspects will ensure that welded gabion mesh continues to thrive in the construction landscape for years to come.

-

Understanding Load-Bearing Capacity of Gabion Boxes

NewsJul.17,2025

-

The Importance of Corrosion-Resistant Wire in Gabion Construction

NewsJul.17,2025

-

How Gabion Boxes Prevent Soil Erosion Effectively

NewsJul.17,2025

-

Environmental Benefits of Gabion Cages

NewsJul.17,2025

-

Best Stone Types for Gabion Walls with Steps

NewsJul.17,2025

-

Benefits of Using Rock Gabion Baskets in Landscaping

NewsJul.17,2025

-

The Role of Galvanized Gabion Mesh in Riverbank Protection

NewsJun.26,2025