Mayo . 07, 2025 19:15 Back to list

Durable Stone Cage Nets Reliable Suppliers & Factories

- Overview of Stone Cage Nets in Modern Construction

- Technical Advantages Over Traditional Solutions

- Market Analysis: Leading Suppliers and Factories

- Customization Options for Diverse Projects

- Case Studies: Successful Applications Worldwide

- Quality Assurance and Industry Compliance

- Why Partner with Professional Stone Cage Net Factories

(stone cage net)

Stone Cage Nets: A Foundation for Sustainable Infrastructure

Stone cage nets, also known as gabion mesh systems, have become indispensable in civil engineering and erosion control. These structures, composed of durable wire mesh filled with stones, offer a blend of flexibility and strength. With a global market projected to grow at 6.8% CAGR through 2030, demand is driven by infrastructure upgrades and climate resilience initiatives. Suppliers and factories specializing in stone cage net

s are increasingly pivotal in delivering solutions for flood management, slope stabilization, and coastal protection.

Technical Superiority in Design and Durability

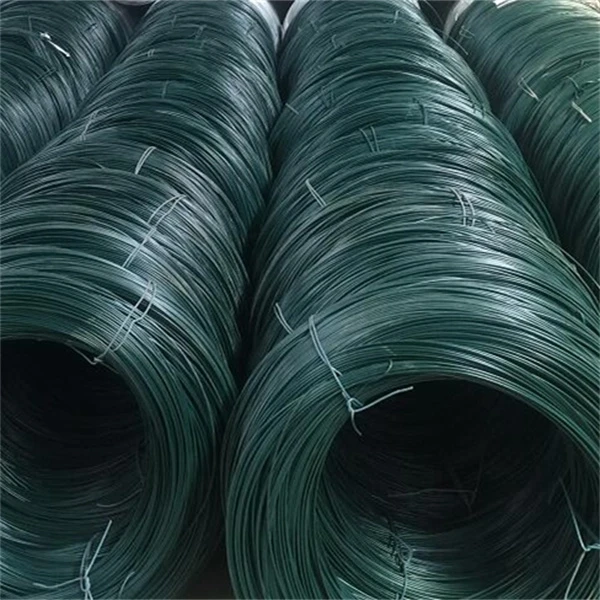

Modern stone cage nets leverage high-tensile steel wires coated with anti-corrosion layers (e.g., Galfan or PVC), extending service life to 50+ years. Compared to concrete retaining walls, gabion systems reduce installation costs by 35% while allowing natural drainage. Advanced welding techniques ensure mesh apertures maintain ±3mm dimensional accuracy, critical for load distribution. Factories now integrate automated production lines, achieving 98% consistency in weld strength across batches.

Supplier Comparison: Key Metrics for Decision-Making

| Supplier | Price per m² (USD) | Production Capacity | Lead Time | Minimum Order |

|---|---|---|---|---|

| Supplier A | $8.50 | 120,000 m²/month | 15 days | 500 m² |

| Supplier B | $7.20 | 90,000 m²/month | 25 days | 1,000 m² |

| Supplier C | $9.10 | 200,000 m²/month | 10 days | 300 m² |

Tailored Solutions for Complex Requirements

Leading factories provide modular designs with variable cell sizes (60x80mm to 100x120mm) and wire diameters (2.0mm to 4.0mm). For a recent highway project in Colorado, engineers specified hexagonal mesh patterns with 3.4mm PVC-coated wires to withstand -30°C conditions. Custom galvanizing processes can achieve zinc coatings up to 300 g/m² for marine environments, tripling corrosion resistance compared to standard offerings.

Global Deployment: Performance in Extreme Conditions

In the Netherlands’ Rhine Delta Project, stone cage nets from certified suppliers prevented €2.3M in potential flood damage during 2023 spring tides. A landslide prevention system in Hong Kong utilized 18,000 m² of double-twist mesh, reducing soil erosion by 92% post-installation. These cases validate gabion structures’ capacity to endure hydraulic pressures exceeding 50 kN/m² while maintaining ecological balance.

Certifications and Testing Protocols

Reputable stone cage net factories adhere to ISO 9001:2015 and ASTM A975 standards. Third-party lab tests typically confirm:

- Mesh tensile strength: 350-500 N/mm²

- Coating adhesion: ≤0.5% loss after 1,000 salt spray hours

- Compression resistance: 1.5x design load without deformation

Strategic Partnerships with Stone Cage Net Experts

Collaborating with established stone cage net suppliers ensures access to engineering support and value-added services. Top-tier factories now offer digital twin simulations, predicting structure behavior under site-specific conditions with 95% accuracy. By combining material science expertise with scalable production, these partners enable cost-efficient infrastructure that meets both technical and environmental benchmarks.

(stone cage net)

FAQS on stone cage net

Q: What is a stone cage net used for?

A: Stone cage nets (gabion mesh) are used for erosion control, slope stabilization, and retaining walls. They provide structural support by holding stones in a wire mesh container. This solution is durable and eco-friendly.

Q: How to choose reliable stone cage net suppliers?

A: Look for suppliers with certifications like ISO, proven industry experience, and positive customer reviews. Request material samples and confirm compliance with international standards. Compare pricing and delivery timelines.

Q: Where are stone cage net factories typically located?

A: Factories are often situated near raw material sources or transportation hubs to reduce costs. Major production regions include China, India, and Europe. Many offer global shipping services.

Q: What materials are used in stone cage net production?

A: Galvanized steel wire or PVC-coated wire is commonly used for corrosion resistance. Mesh sizes and wire thickness vary based on project requirements. Factories perform quality tests to ensure longevity.

Q: Can stone cage net factories customize sizes?

A: Yes, most factories offer custom dimensions, mesh patterns, and coatings. Provide project specifications for tailored solutions. Bulk orders often include design support and discounts.

-

Visualizing Gabion 3D Integration in Urban Landscapes with Rendering

NewsJul.23,2025

-

The Design and Sustainability of Gabion Wire Mesh Panels

NewsJul.23,2025

-

The Acoustic Performance of Gabion Sound Barriers in Urban Environments

NewsJul.23,2025

-

Mastering the Installation of Galvanized Gabion Structures

NewsJul.23,2025

-

Gabion Boxes: Pioneering Sustainable Infrastructure Across the Globe

NewsJul.23,2025

-

Custom PVC Coated Gabion Boxes for Aesthetic Excellence

NewsJul.23,2025

-

Installation Tips for Gabion Wire Baskets in Erosion Control Projects

NewsJul.21,2025