Pro . 22, 2024 04:22 Back to list

gabion aggregate suppliers

Understanding Gabion Aggregate Suppliers

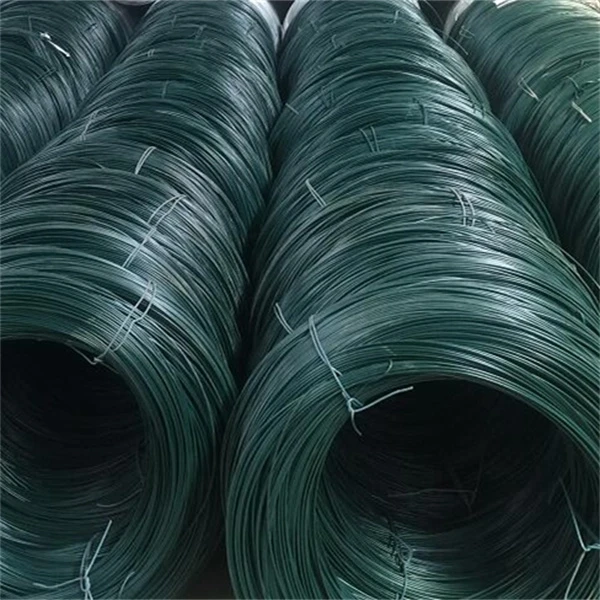

Gabion structures have gained significant popularity in construction and landscaping, serving various purposes such as erosion control, retaining walls, and decorative features. These structures are made of galvanized cages filled with stones known as gabion aggregates. The choice of aggregate is crucial to the durability and functionality of the gabion walls. Thus, understanding the role and offerings of gabion aggregate suppliers becomes essential for anyone involved in construction or landscaping projects.

What are Gabions?

Gabions are wire mesh containers filled with various types of materials, primarily stones. They provide a flexible, strong, and environmentally friendly solution for various engineering and architectural challenges. Gabions are used extensively in civil engineering for slope stabilization, riverbank protection, and even as aesthetically pleasing garden features. The materials used in gabions often include natural stones, recycled concrete, or even innovative options like glass or ceramic aggregates.

The Role of Gabion Aggregate Suppliers

Gabion aggregate suppliers play a vital role in the construction ecosystem. They specialize in providing high-quality aggregates that meet regulatory standards and project specifications. These suppliers source materials from quarries or recycling facilities, ensuring that they are suitable for use in gabion structures.

1. Quality Assurance A reputable supplier ensures that the stones are free from contaminants, adequately sized, and possess the necessary mechanical properties to withstand environmental stressors. Quality aggregates are essential to prevent issues like erosion or structural failure in gabion walls.

2. Variety of Materials Not all projects require the same type of aggregate. Gabion aggregate suppliers often offer a range of materials, including limestone, granite, river rock, recycled concrete, and even decorative stones. This variety allows architects and engineers to select the most suitable material based on aesthetics, cost, and structural integrity.

gabion aggregate suppliers

3. Custom Sizing In some cases, clients may require specific sizes of stones to achieve their design vision or structural requirements. Many suppliers offer services that allow for custom sizing of aggregates, ensuring that each project's unique needs are met.

4. Logistics Coordination Reliable suppliers not only provide quality materials but also assist with logistics. They can manage the transportation of aggregates to the construction site, which can be a complex task given the bulkiness and weight of the materials involved. Coordinating this effectively helps prevent delays in project timelines.

5. Technical Support Experienced gabion aggregate suppliers often have a deep understanding of engineering principles. They can offer valuable advice on material selection, installation techniques, and even maintenance, ensuring project success from start to finish.

Choosing the Right Supplier

When selecting a gabion aggregate supplier, several factors should be considered

- Reputation Look for suppliers with positive reviews and a track record of delivering quality materials on time. - Certifications Ensure the supplier complies with industry standards and regulations. This can help mitigate risks associated with subpar materials. - Cost While cost shouldn't be the only consideration, finding a supplier that offers competitive pricing without compromising on quality is essential. - Customer Service A supplier's willingness to assist and provide guidance can significantly enhance the purchasing experience.

Conclusion

Gabion aggregate suppliers are integral to the construction and landscaping industries. Their expertise, variety of materials, and commitment to quality help ensure that gabion structures are built to last. By carefully selecting a reliable supplier, project managers can optimize both the aesthetic and functional aspects of their gabion installations, contributing to more resilient and appealing outdoor spaces.

-

Installation Tips for Gabion Wire Baskets in Erosion Control Projects

NewsJul.21,2025

-

High-Quality Gabion Basket Barriers for Retaining Wall Systems

NewsJul.21,2025

-

Gabion Welded Wire Mesh Applications in Flood Prevention Systems

NewsJul.21,2025

-

Designing Aesthetic Gabion Wall River Bank

NewsJul.21,2025

-

Creative Garden Gabion Baskets Designs Blending Form and Function

NewsJul.21,2025

-

Cost-Effective Gabion Mesh Panels

NewsJul.21,2025

-

Understanding Load-Bearing Capacity of Gabion Boxes

NewsJul.17,2025