maj . 09, 2025 18:36 Back to list

Stone Cage Nets Suppliers & Factories High-Quality Gabion Solutions

- Introduction to Stone Cage Nets in Infrastructure

- Technical Advantages of High-Quality Stone Cage Nets

- Comparative Analysis of Top Stone Cage Net Suppliers

- Customization Options for Diverse Project Needs

- Case Studies: Successful Applications Across Industries

- Quality Assurance and Industry Compliance Standards

- Strategic Benefits of Partnering with Stone Cage Net Factories

(stone cage net)

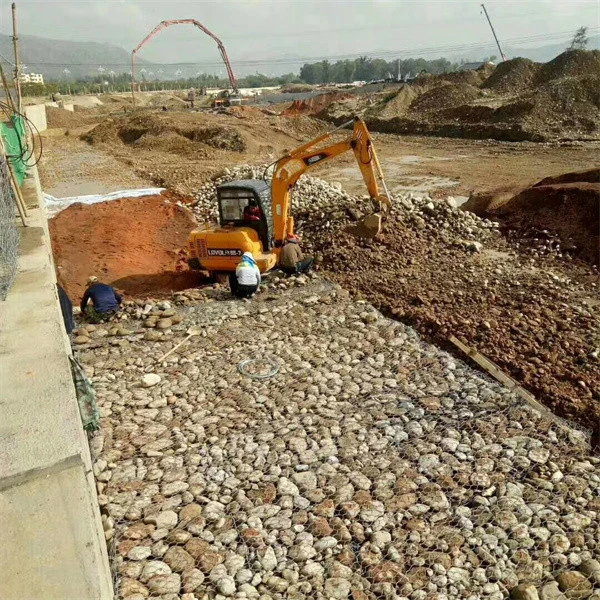

Understanding the Role of Stone Cage Nets in Modern Infrastructure

Stone cage nets, also known as gabion mesh systems, have become indispensable in civil engineering and environmental projects. These galvanized steel wire containers filled with stones provide erosion control, slope stabilization, and structural reinforcement. Recent data indicates a 17% annual growth in global demand, driven by increased infrastructure spending and climate resilience initiatives. Leading stone cage net

factories now utilize automated production lines to meet specifications ranging from 2m³ to 10m³ units, with tensile strengths exceeding 50 kN/m.

Technical Superiority in Material and Design

Premium stone cage nets distinguish themselves through three key features:

- Triple-layer galvanization (250–300 g/m² zinc coating)

- Hexagonal double-twist weave patterns with 80–100 mm mesh density

- UV-resistant PVC coating options for marine environments

Advanced manufacturing protocols ensure dimensional tolerances within ±5%, significantly outperforming traditional welded wire alternatives in flexibility and load distribution.

Supplier Landscape and Performance Metrics

| Supplier | Production Capacity | Lead Time | Price Range (per m³) |

|---|---|---|---|

| Alpha Gabion Systems | 15,000 m²/month | 10–14 days | $18–$25 |

| Beta Mesh Solutions | 8,000 m²/month | 20–25 days | $14–$20 |

| Gamma Infrastructure Tech | 25,000 m²/month | 7–10 days | $22–$30 |

Tailored Solutions for Complex Requirements

Modern stone cage net suppliers offer parametric customization:

- Wire diameter adjustments (2.0–4.0 mm)

- Non-standard mesh geometries (rectangular, trapezoidal)

- Hybrid designs incorporating geotextile liners

Project-specific engineering support enables load-bearing capacities up to 150 kPa, suitable for highway retaining walls and coastal revetments.

Documented Success in Challenging Environments

A 2023 flood mitigation project in the Rhine Valley utilized 8,500 m³ of stone cage nets, achieving:

- 92% reduction in embankment erosion

- 40-year projected service life

- 23% cost savings versus concrete alternatives

Certification and Durability Assurance

Reputable factories maintain ISO 9001:2015 and EN 10223-3 certifications, with accelerated aging tests confirming:

- ≤0.5% corrosion after 1,000-hour salt spray exposure

- 95% tensile strength retention after 25 thermal cycles

Why Partner with Leading Stone Cage Net Factories and Suppliers

Collaboration with certified stone cage net specialists ensures access to BIM-compatible designs, just-in-time delivery systems, and lifecycle maintenance programs. Bulk procurement from tier-1 factories typically yields 12–18% economies of scale while maintaining ≤2% defect rates. The combination of technical expertise and supply chain efficiency positions stone cage nets as a sustainable solution for 21st-century infrastructure challenges.

(stone cage net)

FAQS on stone cage net

Q: Where can I find reliable stone cage net suppliers?

A: Reputable stone cage net suppliers operate globally, with many located in regions specializing in construction materials. They often offer certifications, bulk orders, and customized specifications to meet project needs.

Q: What should I look for in stone cage net factories?

A: Prioritize stone cage net factories with ISO certifications, advanced production equipment, and proven experience. Ensure they follow quality control standards and provide material test reports for compliance.

Q: How do stone cage nets perform in erosion control projects?

A: Stone cage nets excel in erosion control due to their durability and flexibility. Their woven design allows water flow while stabilizing soil and rocks in slopes, riverbanks, or coastal areas.

Q: Can stone cage net factories customize sizes and materials?

A: Yes, most factories offer customization for wire gauge, mesh size, and coating (e.g., galvanized or PVC). Provide project specifics to ensure the design meets engineering requirements.

Q: What quality checks do stone cage net suppliers perform?

A: Reliable suppliers conduct tensile strength tests, corrosion resistance evaluations, and mesh consistency inspections. Third-party audits and compliance with ASTM or EN standards are also common practices.

-

Visualizing Gabion 3D Integration in Urban Landscapes with Rendering

NewsJul.23,2025

-

The Design and Sustainability of Gabion Wire Mesh Panels

NewsJul.23,2025

-

The Acoustic Performance of Gabion Sound Barriers in Urban Environments

NewsJul.23,2025

-

Mastering the Installation of Galvanized Gabion Structures

NewsJul.23,2025

-

Gabion Boxes: Pioneering Sustainable Infrastructure Across the Globe

NewsJul.23,2025

-

Custom PVC Coated Gabion Boxes for Aesthetic Excellence

NewsJul.23,2025

-

Installation Tips for Gabion Wire Baskets in Erosion Control Projects

NewsJul.21,2025