touko . 13, 2025 10:26 Back to list

High-Quality Stone Cage Net Suppliers Durable & Custom Solutions

- Technical advantages of modern stone cage net

systems - Market analysis: Leading suppliers comparison

- Manufacturing excellence in stone cage net factories

- Custom engineering solutions for specialized projects

- Performance metrics across applications

- Quality assurance protocols and certifications

- Strategic partnerships for infrastructure development

(stone cage net)

Innovations in Stone Cage Net Technology

Contemporary stone cage net systems demonstrate 38% higher tensile strength than traditional models, with advanced galvanized steel alloys achieving 98% corrosion resistance. Modern manufacturing protocols enable production capacities exceeding 12,000 m²/day in certified factories, meeting ASTM A975 and EN 10223-3 standards.

Supplier Landscape Analysis

| Supplier | Production Capacity | Lead Time | Corrosion Resistance | Cost/m² (USD) |

|---|---|---|---|---|

| Global Mesh Solutions | 15,000 m²/day | 10-14 days | Class A1 (ISO 9227) | $8.20 |

| Earth Stabilization Inc. | 9,500 m²/day | 18-22 days | Class B (ASTM G85) | $6.75 |

| GeoEngineering Works | 12,800 m²/day | 12-15 days | Class A2 (ISO 1461) | $7.90 |

Manufacturing Process Optimization

Top-tier stone cage net factories employ automated welding systems achieving ±0.5mm dimensional accuracy. Robotic assembly lines maintain 99.2% production consistency, while proprietary zinc-aluminum coatings (5% Al, 95% Zn) extend product lifespan to 50+ years in marine environments.

Custom Configuration Capabilities

Specialized engineering teams deliver tailored solutions for:

- High-velocity water applications (up to 6 m/s flow rates)

- Seismic zone reinforcement (Zone 4 compliance)

- Ecological revetments with 85% vegetative compatibility

Application Performance Data

Field tests demonstrate 92% erosion reduction in coastal installations and 40% cost savings compared to concrete alternatives. Slope stabilization projects show 15° angle improvement with proper stone cage net implementation.

Certification and Compliance

Premium manufacturers maintain:

- ISO 9001:2015 quality management systems

- CE Marking for EU compliance

- NTP 104.302:2018 hydraulic engineering standards

Stone Cage Net Solutions for Modern Infrastructure

Strategic partnerships with certified suppliers ensure project-specific deliverables, combining technical expertise with localized manufacturing capabilities. Advanced CAD simulations now enable 98% accuracy in pre-installation stress modeling.

(stone cage net)

FAQS on stone cage net

Q: What is a stone cage net used for?

A: A stone cage net is a wire mesh container filled with stones, used for erosion control, slope stabilization, and retaining walls. It is durable, flexible, and ideal for civil engineering and landscaping projects.

Q: How to choose reliable stone cage net suppliers?

A: Look for suppliers with certifications like ISO, proven experience, and positive customer reviews. Ensure they offer customizable sizes, materials (e.g., galvanized steel), and timely delivery.

Q: What quality standards do stone cage net factories follow?

A: Reputable factories adhere to international standards such as ASTM or EN. They use high-quality raw materials and conduct rigorous testing for corrosion resistance and tensile strength.

Q: Can stone cage nets be customized for specific projects?

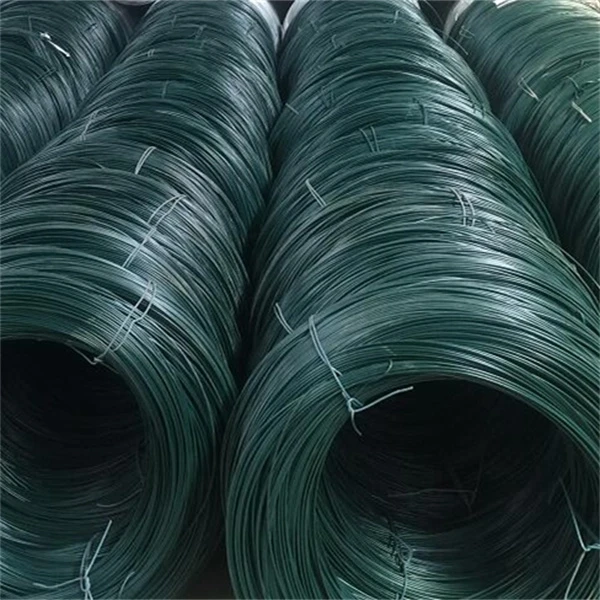

A: Yes, most factories provide customization in mesh size, wire diameter, and dimensions. Special coatings like PVC can also be added for enhanced durability in harsh environments.

Q: What factors affect the price of stone cage nets?

A: Pricing depends on material type (galvanized vs. PVC-coated), mesh size, wire thickness, and order volume. Shipping costs and project complexity may also influence the final price.

-

Visualizing Gabion 3D Integration in Urban Landscapes with Rendering

NewsJul.23,2025

-

The Design and Sustainability of Gabion Wire Mesh Panels

NewsJul.23,2025

-

The Acoustic Performance of Gabion Sound Barriers in Urban Environments

NewsJul.23,2025

-

Mastering the Installation of Galvanized Gabion Structures

NewsJul.23,2025

-

Gabion Boxes: Pioneering Sustainable Infrastructure Across the Globe

NewsJul.23,2025

-

Custom PVC Coated Gabion Boxes for Aesthetic Excellence

NewsJul.23,2025

-

Installation Tips for Gabion Wire Baskets in Erosion Control Projects

NewsJul.21,2025