Nov . 01, 2024 20:06 Back to list

Gabion Basket Manufacturing Tools and Equipment for Optimal Construction Solutions

The Versatility of Gabion Baskets A Deep Dive into Factory Tools and Techniques

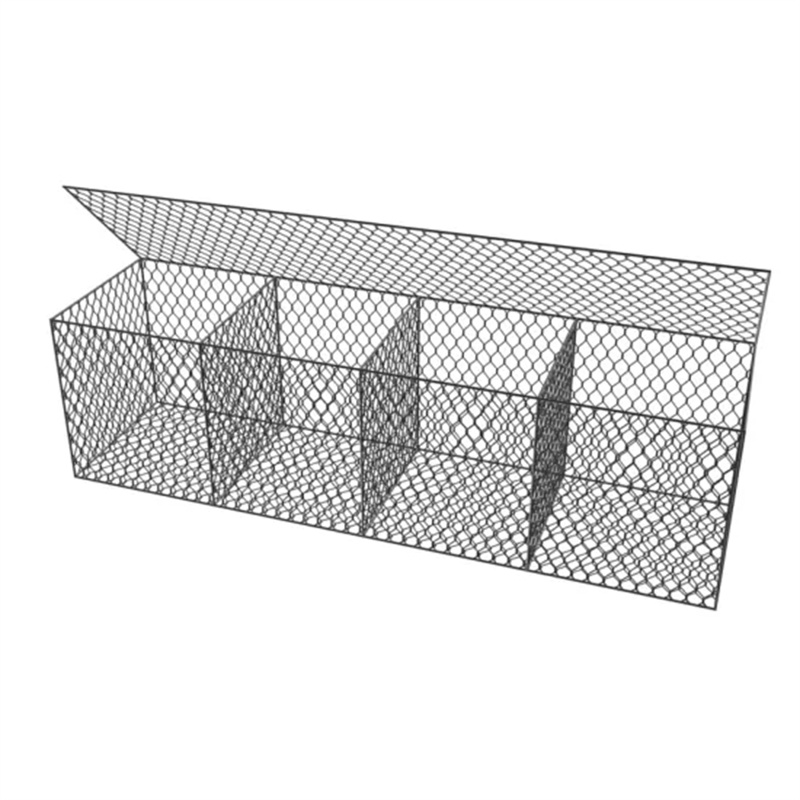

Gabion baskets have emerged as one of the most practical and aesthetically pleasing solutions in landscaping and civil engineering. These wire mesh containers filled with rocks or concrete are versatile, durable, and perfect for erosion control, retaining walls, and even decorative features. To ensure the highest quality of gabion baskets, specialized factory tools and techniques play a crucial role in their production.

The Versatility of Gabion Baskets A Deep Dive into Factory Tools and Techniques

Once the mesh is manufactured, the next step involves forming the gabion baskets into their desired shapes and sizes. This requires specialized cutting and bending tools that allow for customization according to specific project requirements. Factories often employ CNC (Computer Numerical Control) machines for this purpose, which provide exceptional control over the dimensions and cuts, minimizing waste and maximizing efficiency.

gabion basket tools factory

After forming, the baskets undergo a treatment process to enhance their resistance to corrosion. This involves dipping the baskets in a protective coating or using polymer-based treatments that extend the lifespan of the wire mesh. Factories equipped with advanced treatment lines can efficiently apply these coatings, ensuring that each basket meets quality standards.

Quality control is another vital aspect of gabion basket production. Factories implement thorough testing procedures to ensure that each basket can bear the required load and withstand environmental stressors. Tools such as tensile testers and salt spray chambers are used to evaluate the durability and performance of the materials, guaranteeing that only the best products leave the factory.

Finally, the logistics of packaging and shipping gabion baskets require careful planning. Factories utilize specialized packing tools to ensure that the baskets are securely bundled and protected during transit. Proper packaging not only prevents damage but also facilitates efficient delivery to construction sites and landscaping projects.

In conclusion, the production of gabion baskets is a meticulous process that relies heavily on advanced factory tools and techniques. From high-quality materials to precision manufacturing and rigorous quality control, every step is crucial in creating durable and effective gabion structures. As demand for sustainable and innovative landscaping solutions continues to grow, the importance of sophisticated technology in gabion basket factories will only increase.

-

The Role of Galvanized Gabion Mesh in Riverbank Protection

NewsJun.26,2025

-

The Role of Gabion Basket Raised Bed in Sustainable Gardening

NewsJun.26,2025

-

Quality Assurance of Wire Mesh Gabion Baskets

NewsJun.26,2025

-

Installation Guide for Welded Gabion Box

NewsJun.26,2025

-

How to Choose the Right Gabion Box

NewsJun.26,2025

-

Different Types of Gabion Wire Mesh

NewsJun.26,2025

-

Why PVC Coated Gabion Mattress Is the Best Solution for Long-Term Erosion Control

NewsMay.23,2025