सितम्बर . 08, 2024 07:29 Back to list

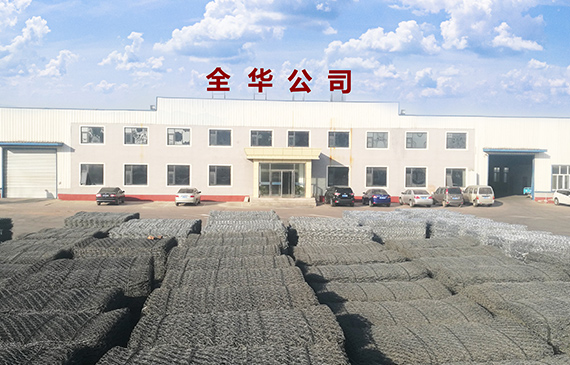

Gabion Tie Wire Manufacturers - Durable and Reliable Solutions

The Role of Gabion Tie Wire Factories in Sustainable Construction

In recent years, the construction industry has seen a significant shift towards sustainable practices. One of the essential components contributing to this trend is gabion tie wire, a crucial element in the construction of retaining walls, erosion control structures, and various landscaping projects. Gabion tie wire factories play a pivotal role in supplying this product, supporting not just construction but also environmental sustainability.

Gabions, essentially wire mesh baskets filled with stones, are known for their strength, durability, and versatility. They have been used for centuries, but their popularity has surged in modern construction due to their eco-friendly characteristics. The primary function of gabion tie wire is to hold these mesh baskets together, ensuring structural integrity and effectiveness in their application. The manufacturing process of gabion tie wire involves various stages, which include wire drawing, galvanizing, and packaging.

Wire Drawing and Quality Control

The journey of creating gabion tie wire begins in the wire drawing stage. Raw steel is processed to create wires of desired gauges, which are then subjected to strict quality control measures. Factories focus on producing high-tensile strength wires, ensuring that they can withstand harsh environmental conditions. Quality is paramount as substandard materials could fail, causing catastrophic failures in gabion structures. Regular inspections and adherence to international standards help maintain quality, making gabion tie wire factories crucial in delivering reliable products.

Galvanization for Longevity

Once wire drawing is complete, the next crucial step is galvanization. This process involves coating the wire with zinc to prevent corrosion, which is particularly important in outdoor applications. Gabion structures typically face exposure to water and varying weather conditions, which can lead to rust and degradation over time. A well-galvanized wire can extend the lifespan of gabion systems significantly, making it a cost-effective choice for long-term projects. Many factories also offer additional coatings, such as PVC, to enhance durability and aesthetics, catering to the growing demand for versatile landscaping solutions.

gabion tie wire factories

Supporting Local Economies

Gabion tie wire factories are often local businesses that support regional economies. By providing jobs and procuring materials from local suppliers, these factories contribute to economic growth and stability. In addition to manufacturing, some factories offer training programs for workers to enhance their skills in metalworking and manufacturing processes. This investment in human capital helps create a skilled workforce that can adapt to changing technologies and market demands.

Sustainability and Environmental Impact

The use of gabions made with tie wire significantly reduces the environmental impact of construction projects. Gabions can utilize locally sourced stones, minimizing transportation costs and carbon footprints. Additionally, they can help in stabilizing slopes, controlling erosion, and promoting biodiversity in landscaping projects. The ecological benefits inherent in gabion systems align closely with the growing emphasis on sustainability in the construction industry.

Conclusion

In conclusion, gabion tie wire factories are more than just manufacturers; they are integral to fostering sustainable construction practices. By producing high-quality tie wire, these factories ensure the reliability and longevity of gabion structures, supporting both local economies and environmental initiatives. As the construction industry continues to evolve, the importance of such factories cannot be overstated. Their contributions will undoubtedly play a pivotal role in shaping a more sustainable future for construction. Whether for large infrastructural projects or small landscaping endeavors, gabion tie wire remains essential, showcasing the interconnectedness of industry and ecology.

-

Why PVC Coated Gabion Mattress Is the Best Solution for Long-Term Erosion Control

NewsMay.23,2025

-

Gabion Wire Mesh: The Reinforced Solution for Modern Construction and Landscape Design

NewsMay.23,2025

-

Gabion Wall: The Flexible, Seismic-Resistant Solution for Modern Landscaping and Construction

NewsMay.23,2025

-

Gabion Wall Solutions: The Durable, Decorative, and Affordable Choice for Every Landscape

NewsMay.23,2025

-

Gabion Basket: The Durable and Flexible Alternative to Traditional Retaining Walls

NewsMay.23,2025

-

Gabion Basket: The Proven Solution for Slope Stability and Flood Control

NewsMay.23,2025

-

Versatility of Chain Link Fence Gabion

NewsMay.13,2025