აგვ . 09, 2025 00:20 Back to list

Wholesale Galvanized Hesco Barrier for Military Defense

In an increasingly complex global landscape, the demand for robust, rapidly deployable, and effective defensive structures is paramount. From safeguarding critical infrastructure to providing essential flood control and establishing secure perimeters in conflict zones, engineered solutions are vital. Among these, the Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers stand out as a cornerstone of modern defensive and civil engineering applications. This comprehensive guide delves into the specifics of these advanced barriers, exploring their industry impact, technical prowess, diverse applications, and the strategic advantages they offer to a wide array of sectors.

Industry Trends and Market Dynamics for Defensive Barriers

The market for defensive barriers, particularly those designed for rapid deployment and high efficacy, is experiencing significant growth. Geopolitical shifts, increased frequency of natural disasters, and ongoing infrastructure development projects are primary drivers. There's a noticeable trend towards materials that offer superior corrosion resistance and longevity, coupled with designs that facilitate quicker assembly and disassembly. Clients are increasingly seeking solutions that are not only effective in their primary function—be it ballistic protection, flood mitigation, or erosion control—but also cost-efficient, environmentally adaptable, and compliant with international standards.

Recent reports indicate a compound annual growth rate (CAGR) for the global defensive barrier market of approximately 5-7% over the next five years, driven largely by government and military expenditures, alongside a burgeoning civilian demand for disaster preparedness. The emphasis on modularity and reusability also shapes current industry innovations. For instance, the demand for Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers is propelled by their inherent flexibility and adaptability to various terrains and threat levels, making them a preferred choice for military, humanitarian, and civil engineering organizations worldwide.

The shift towards sustainable engineering practices also influences the adoption of these barriers. Their ability to be filled with locally sourced materials like sand, earth, or gravel reduces logistical burdens and environmental impact compared to traditional construction methods requiring concrete or steel structures. This aspect, combined with their proven track record in high-stakes environments, cements their position as a leading solution in the defense and protection industry.

Technical Parameters and Specifications: The Engineering Behind the Barrier

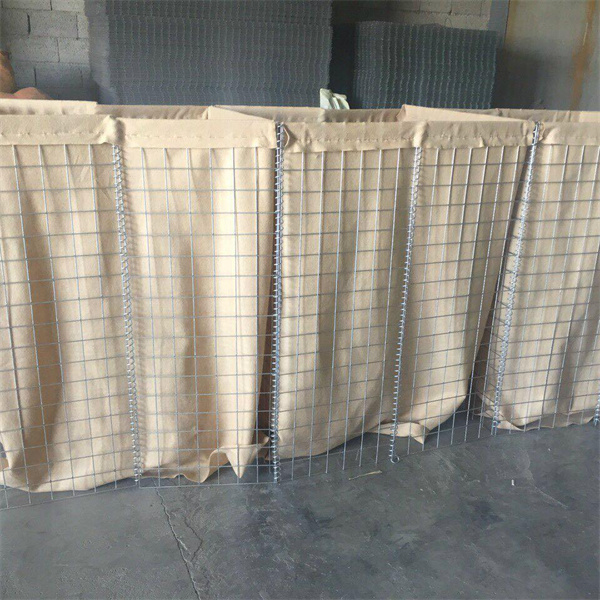

The effectiveness of a Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers lies in its meticulously engineered design and material composition. These barriers typically consist of a collapsible wire mesh container111, internally lined with a heavy-duty, non-woven polypropylene geotextile fabric. This fabric allows for the containment of fill material while enabling water drainage, preventing hydrostatic pressure buildup.

Key Specifications and Material Properties:

- Material of Construction: High-quality galvanized steel wire or Galfan-coated wire. Galvanization provides a sacrificial zinc coating that protects the steel from corrosion, extending the product's lifespan significantly even in harsh environments. Galfan, an alloy of zinc-aluminum, offers even superior corrosion resistance, sometimes up to three times that of standard hot-dip galvanization.

- Mesh Wire Diameter: Typically ranges from 4.0mm to 5.0mm (approximately 8-6 gauge), offering a robust framework. Thicker wires enhance the barrier's structural integrity and resistance to deformation under impact.

- Mesh Opening: Common sizes include 75mm x 75mm (3" x 3") or 50mm x 50mm (2" x 2"), providing optimal support for the geotextile liner and fill material without allowing excessive bulging.

- Geotextile Liner: Heavy-duty non-woven polypropylene, typically 250gsm to 300gsm (grams per square meter). This material is UV resistant, durable, and permeable, ensuring proper drainage.

- Standard Unit Sizes: Modular units are designed to be connected, forming continuous barriers of various lengths and heights. Common dimensions (Height x Width x Length) include:

- 1.0m x 1.0m x 10m (3.28 ft x 3.28 ft x 32.8 ft) - often used for lower walls or perimeter definition.

- 1.5m x 1.0m x 10m (4.92 ft x 3.28 ft x 32.8 ft)

- 2.13m x 1.06m x 15m (7 ft x 3.5 ft x 49.2 ft) - very common for military applications.

- 2.21m x 2.13m x 10m (7.25 ft x 7 ft x 32.8 ft) - larger units for significant protection.

- 2.4m x 1.2m x 12m (7.87 ft x 3.94 ft x 39.37 ft)

- Connection System: Units are connected via robust spiral wires or C-clips, forming an interconnected, stable structure. This allows for rapid deployment and flexibility in barrier design.

- Fill Material Capacity: The volume of fill material (sand, earth, gravel, small rocks) directly relates to the barrier's protective capacity. A standard unit like a 2.13m x 1.06m x 15m barrier can hold cubic meters of material, providing significant mass for ballistic protection or flood resistance.

- Service Life: When properly installed and maintained, and depending on the level of galvanization or Galfan coating, these barriers can have a service life exceeding 10-20 years in typical outdoor conditions. UV-resistant geotextile is crucial for long-term performance.

- Deployment Speed: Extremely rapid compared to traditional sandbagging or concrete construction. A small team can deploy hundreds of meters of barrier in a day using minimal heavy equipment.

- Ballistic Protection Levels: When filled correctly, these barriers can offer significant protection against small arms fire, indirect fire, and vehicle-borne improvised explosive devices (VBIEDs), depending on the barrier's dimensions and the density of the fill material. Specific protection levels are often tested against STANAG standards, although this is proprietary data for military applications.

Comprehensive Parameter Table:

The table below summarizes typical specifications for the Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers:

| Parameter | Typical Value Range | Notes |

|---|---|---|

| Wire Diameter | 4.0mm - 5.0mm (8-6 Gauge) | Higher gauge (smaller number) indicates thicker wire, stronger barrier. |

| Mesh Opening | 75mm x 75mm (3" x 3") or 50mm x 50mm (2" x 2") | Affects stability and retention of fill material. |

| Material Coating | Hot-Dipped Galvanized Steel (275g/m² minimum zinc coating) / Galfan (Zn-Al alloy) | Ensures long-term corrosion resistance, meeting ASTM A123 or EN 10244-2 standards. |

| Geotextile Liner | Heavy-duty Non-Woven Polypropylene, 250-300 GSM | UV stabilized, permeable, and durable; meets ASTM D4632 (Tensile Strength) & D4533 (Trapezoidal Tear). |

| Unit Height (H) | 1.0m, 1.5m, 2.0m, 2.13m, 2.21m, 2.4m | Adaptable to various defensive or flood wall heights. |

| Unit Width (W) | 1.0m, 1.06m, 1.2m, 2.13m | Determines the base stability and protective thickness. |

| Unit Length (L) (Folded) | Up to 30m (for multi-cell units) | Modular design allows for custom lengths by connecting units. |

| Tensile Strength of Mesh (Welded Joint) | > 450 N/mm² | Reflects the strength of the welded joints to withstand pressure. |

| Expected Service Life | 10-20+ Years | Depends on coating type, environmental exposure, and maintenance. |

| Deployment Time | Minutes per meter (with proper equipment) | Significantly faster than traditional methods. |

| Fill Material | Sand, Earth, Gravel, Crushed Rock | Locally available, cost-effective, and environmentally friendly. |

These specifications are critical for ensuring the performance and reliability of the Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers in demanding applications.

The Manufacturing Process: From Wire to Robust Barrier

The production of a Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers involves a meticulous process that ensures durability, strength, and reliability. This is not a simple assembly line; it's a precision manufacturing operation designed to meet stringent military and civil engineering standards. The core processes involve wire drawing, welding, galvanization, geotextile cutting and sewing, and final assembly.

Detailed Manufacturing Process:

While an actual video or interactive schematic isn't possible in this text format, imagine the following sequential steps, often depicted with flow arrows and key descriptive nodes:

Step 1: Wire Rod Selection & Drawing

The process begins with high-quality steel wire rods. These rods are drawn through a series of dies to achieve the precise wire diameter required (e.g., 4.0mm to 5.0mm). This cold drawing process enhances the wire's tensile strength and uniformity, which is critical for the integrity of the finished barrier.

Key Node: Wire Quality Control (Material composition verification, ISO 9001 adherence)

Step 2: Automated Wire Welding

The drawn wires are then fed into highly automated welding machines. These machines precisely position the horizontal and vertical wires and use resistance welding to create strong, consistent mesh panels with uniform mesh openings (e.g., 75mm x 75mm). The quality of these welds is paramount for the barrier's structural integrity under load.

Key Node: Weld Strength Testing (Ensuring consistent joint strength, compliance with ASTM A185 for welded steel wire fabric)

Step 3: Hot-Dip Galvanization or Galfan Coating

After welding, the mesh panels undergo a rigorous cleaning and pickling process to remove impurities. They are then immersed in a bath of molten zinc (for hot-dip galvanization) or a zinc-aluminum alloy (for Galfan coating). This process forms a metallurgically bonded protective layer on the steel surface, offering superior corrosion resistance. The thickness of this coating is carefully controlled to meet international standards like ASTM A123 or EN 10244-2, ensuring a long service life of 10-20+ years, even in corrosive environments.

Key Node: Coating Thickness Measurement & Adhesion Test (Ensuring uniform, durable coating)

Step 4: Geotextile Liner Preparation

Concurrently, rolls of heavy-duty, UV-stabilized non-woven polypropylene geotextile fabric (typically 250-300 GSM) are cut to precise dimensions. The edges are then sewn to form an internal liner bag, designed to fit snugly within the mesh cells. High-strength stitching is used to prevent tearing during filling and deployment.

Key Node: Geotextile Quality Control (Tensile strength, UV resistance, permeability testing)

Step 5: Assembly and Connection System Integration

The galvanized mesh panels are then folded and assembled into their collapsible, multi-cell form. Spiral wires (helical coils) or robust C-clips are integrated into the design to allow for easy and secure connection of individual units on-site. The pre-fabricated geotextile liners are then inserted into each cell.

Key Node: Assembly Fit & Finish Inspection (Ensuring ease of deployment and structural integrity of connections)

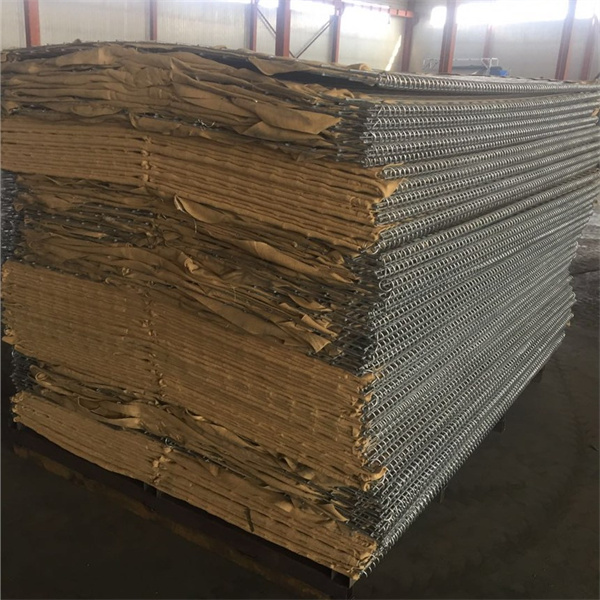

Step 6: Quality Inspection and Packaging

Each completed Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers unit undergoes a final, comprehensive quality inspection. This includes checking dimensions, weld integrity, coating quality, geotextile condition, and overall functionality. Once approved, the units are compacted, folded, and securely packaged, typically on pallets, for efficient transport and storage.

Key Node: Final Product Quality Assurance (Adherence to all specified parameters, third-party certifications like ISO 9001:2015 for quality management)

This stringent manufacturing process ensures that each Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers meets the highest standards of performance and reliability, making it suitable for critical applications across various industries.

Technical Advantages: Why Choose Hesco Barriers?

The inherent design and material science behind the Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers confer a multitude of technical advantages over conventional defensive structures. These benefits translate directly into superior performance, cost-effectiveness, and operational efficiency.

Superior Corrosion Resistance:

The use of hot-dip galvanized or Galfan-coated steel wire provides an exceptional level of protection against rust and corrosion. Unlike ungalvanized steel or some other materials that degrade rapidly in harsh outdoor or marine environments, the zinc or zinc-aluminum alloy coating acts as a sacrificial layer, significantly extending the barrier's operational lifespan. This is particularly crucial in coastal areas, high-humidity regions, or environments exposed to chemical agents, where traditional materials would quickly deteriorate. This anti-corrosion property reduces maintenance needs and ensures the barrier retains its structural integrity over decades.

Rapid Deployment and Installation:

One of the most significant advantages is the speed of deployment. Unlike concrete or traditional sandbagging, which are labor-intensive and time-consuming, Hesco barriers can be deployed and filled rapidly using readily available earthmoving equipment (e.g., front-end loaders, excavators). A small team can erect and fill hundreds of meters of barrier in a single day, a feat impossible with conventional methods. This rapid response capability is invaluable in emergency situations, such as sudden flood events or urgent security needs, where time is of the essence.

Structural Integrity and Durability:

The welded mesh construction creates a strong, interconnected framework. When filled with local material, the modular units become a cohesive, massive structure capable of absorbing significant impact and resisting deformation. The geotextile liner prevents the fill material from escaping, maintaining the barrier's mass and shape. This robust design provides superior blast mitigation and ballistic protection compared to loose sandbags, making the Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers highly effective against various threats, from small arms fire to vehicular impacts.

Cost-Effectiveness and Logistical Efficiency:

While the initial unit cost might seem higher than a single sandbag, the overall cost-effectiveness is immense. The speed of deployment dramatically reduces labor costs. Furthermore, the ability to fill units with locally available materials (sand, earth, gravel) eliminates the need for transporting large quantities of specialized building materials, reducing logistical footprints and transportation costs. This efficiency makes them an economically viable solution for large-scale projects and emergency responses.

Environmental Adaptability:

Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers are incredibly versatile and can be deployed on various terrains, from rocky ground to soft soil. Their modular nature allows them to conform to irregular landscapes. When their purpose is served, the fill material can often be dispersed back into the environment, and the empty mesh units are collapsible for easy removal or storage. This adaptability makes them ideal for temporary or semi-permanent installations in diverse ecological settings.

Versatility and Multi-Purpose Applications:

Beyond their primary role in military defense, these barriers serve a wide range of civilian applications. Their adaptability allows them to be used for flood control, erosion prevention, civil construction (e.g., retaining walls, noise barriers), and even environmental protection. This multi-functionality adds to their value proposition, making them a go-to solution for various engineering challenges.

In summary, the technical advantages of the Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers—including superior corrosion resistance, rapid deployment, exceptional structural integrity, cost-effectiveness, environmental adaptability, and versatility—position them as a leading solution for modern defensive and civil engineering needs.

Application Scenarios: Where These Barriers Make a Difference

The versatility and robust nature of the Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers enable their deployment across an extensive range of critical applications. Their ability to provide immediate and effective protection in diverse environments has made them indispensable in both military and civilian sectors.

1. Military and Security Applications:

- Force Protection: Creating defensive positions, checkpoints, bunkers, and forward operating bases (FOBs) against ballistic threats, rocket-propelled grenades (RPGs), and indirect fire. Their modularity allows for rapid construction of protective walls around personnel and equipment.

- Perimeter Security: Establishing robust perimeter fences and entry control points (ECPs) for military installations, embassies, and high-security zones. The sheer mass of a filled barrier provides a formidable physical deterrent.

- Ammunition & Fuel Storage Protection: Building protective berms around sensitive materials to contain potential blasts or mitigate damage from external attacks.

- Training Exercises: Used for creating temporary firing ranges, obstacle courses, and mock defensive structures for realistic training scenarios.

2. Flood Control and Disaster Relief:

- Temporary Flood Barriers: Rapidly deploying walls to prevent water ingress during flash floods or rising river levels, protecting communities and critical infrastructure. Their ability to be filled with readily available sand or earth makes them ideal for emergency response.

- Levee Reinforcement: Used to reinforce existing levees or construct temporary embankments to prevent overflow and erosion.

- Debris Containment: Containing mudslides, rockfalls, or debris flows in disaster-stricken areas, helping to channel or block hazardous materials.

- Post-Disaster Reconstruction: Providing temporary housing foundations or protective barriers around damaged areas during recovery efforts.

3. Civil Engineering and Construction:

- Erosion Control: Building retaining walls or slope stabilization structures along roads, railways, or coastlines to prevent soil erosion and landslides. The permeable nature of the geotextile allows for water drainage while containing soil.

- Temporary Access Roads: Creating stable bases for temporary roads and work platforms on soft or challenging terrain, particularly in remote construction sites.

- Noise Barriers: Constructing effective noise attenuation walls near highways, industrial sites, or urban construction zones to reduce sound pollution. The dense fill material provides excellent sound absorption.

- Site Security: Securing construction sites from unauthorized access or theft of materials, especially in remote or high-risk areas.

4. Mining and Industrial Applications:

- Tailings Dam Reinforcement: Used to reinforce and stabilize tailings dams in mining operations, providing a robust and permeable structure.

- Equipment Protection: Creating protective bunkers or barriers around sensitive mining equipment or hazardous material storage areas.

- Blast Mitigation: In quarries or industrial settings where controlled blasting occurs, these barriers can be used to contain debris and enhance safety.

5. Environmental and Landscaping:

- Shoreline Protection: Used in coastal areas to mitigate erosion and protect sensitive ecosystems from wave action and storm surges.

- Landfill Containment: Forming cells or containment structures within landfills for waste management.

- Decorative Elements: In some innovative landscaping designs, smaller Hesco-style gabions can be used for aesthetic retaining walls or garden features, filled with decorative stone.

The broad spectrum of applications for the Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers underscores their unparalleled adaptability and effectiveness as a multi-functional protective solution, catering to both urgent tactical needs and long-term civil engineering requirements. Their proven performance in diverse, high-stress environments solidifies their reputation as a reliable and essential component in modern protective strategies.

Manufacturer Comparison and Selection Criteria

When sourcing Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers, choosing the right manufacturer is as crucial as understanding the product itself. The market has various suppliers, but not all adhere to the same rigorous quality standards or offer comprehensive support. Here’s a guide to comparing manufacturers and key selection criteria:

Key Comparison Points:

- Material Quality and Certifications:

- Wire Material: Verify the origin and grade of the steel wire. Reputable manufacturers will use high-tensile steel that meets international standards (e.g., ASTM A641 for metallic coated carbon steel wire).

- Galvanization/Galfan Coating: Crucially, confirm the coating weight and type. ISO 1461 for hot-dip galvanized coatings or EN 10244-2 for wire coatings are critical benchmarks. Higher coating weights (e.g., 275g/m² minimum for hot-dip) ensure longer lifespan.

- Geotextile Liner: Inquire about the GSM (grams per square meter) and UV resistance of the polypropylene liner. A minimum of 250 GSM and proven UV stabilization are essential for durability. Request test certificates (e.g., ASTM D4632 for tensile strength).

- Manufacturing Process and Quality Control:

- Welding Quality: Examine the consistency and strength of welded mesh joints. Automated welding processes generally yield superior, uniform welds. Reputable manufacturers conduct pull tests on welds.

- ISO Certification: A manufacturer with ISO 9001:2015 certification demonstrates a commitment to quality management systems throughout their production process, from raw material sourcing to final product inspection.

- Production Capacity: For large-scale projects, ensure the manufacturer has the capacity to meet your volume and delivery timelines without compromising quality.

- Product Range and Customization:

- Does the manufacturer offer a full range of standard Hesco barrier sizes, or only a limited selection?

- Can they provide custom dimensions or configurations if your project has unique requirements? This includes specialized heights, widths, or multi-cell designs.

- Are accessories like connecting pins/spirals readily available and compatible?

- Pricing and Value Proposition:

- While price is a factor, prioritize value. A slightly higher-priced product with superior materials, certifications, and longer lifespan often proves more cost-effective in the long run due to reduced replacement and maintenance costs.

- Inquire about bulk discounts and tiered pricing for larger orders.

- Logistics and Delivery:

- Assess their ability to handle international shipping and provide efficient logistics solutions.

- What are their typical lead times and on-time delivery rates?

- Do they offer flexible packaging solutions for ease of transport and site handling?

- Customer Support and After-Sales Service:

- Do they provide technical support, installation guides, or on-site assistance if needed?

- What is their warranty policy for the product? A clear warranty instills confidence.

- Are they responsive to inquiries and provide clear communication?

- Industry Reputation and Experience:

- How long has the manufacturer been in business? Longevity often correlates with stability and experience.

- Check for client testimonials, case studies, or reference projects. Partnerships with government agencies, NGOs, or large construction firms are good indicators.

Manufacturer Example Comparison (Illustrative, not specific companies):

| Feature/Criteria | Manufacturer A (Premium) | Manufacturer B (Standard) | Manufacturer C (Budget) |

|---|---|---|---|

| Wire Material | Galfan-coated Steel (Zn-Al alloy) | Hot-Dip Galvanized Steel (275g/m²) | Electro-Galvanized Steel (Lower coating) |

| Mesh Wire Dia. | 5.0mm (6 Gauge) | 4.0mm (8 Gauge) | 3.5mm (9 Gauge) |

| Geotextile Liner | 300 GSM UV Stabilized PP | 250 GSM UV Stabilized PP | 200 GSM Non-UV Stabilized PP |

| Certifications | ISO 9001, ASTM, CE | ISO 9001 | None specified |

| Customization | Full custom options available | Standard sizes, limited custom | Only standard sizes |

| Warranty | 15-Year Product Warranty | 5-Year Product Warranty | Limited or No Warranty |

| Technical Support | Extensive, On-site possible | Online/Phone support | Basic support |

| Typical Lead Time | 2-4 Weeks | 4-6 Weeks | 6-8 Weeks |

This comparison highlights that while a "budget" option might seem appealing upfront, it often sacrifices long-term durability, compliance, and support, which can lead to higher total cost of ownership. For critical applications requiring the utmost reliability and longevity, investing in a premium manufacturer of Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers is always the wisest choice.

Customization Solutions for Specific Needs

While standard sizes of Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers meet most requirements, specific projects often demand tailored solutions. Reputable manufacturers offer extensive customization options to ensure the barriers perfectly fit the unique challenges of a given application. This flexibility is a significant advantage, allowing for optimized performance and efficiency.

Areas of Customization:

- Dimensions (Height, Width, Length):

- Non-Standard Heights: For specific defensive levels or flood control requirements where standard 1.0m, 1.5m, or 2.13m heights are not optimal. For instance, a 0.7m high barrier for low-level erosion control or a 3.0m high barrier for maximum ballistic protection.

- Custom Widths (Base): To achieve specific stability or protective mass. A wider base provides greater resistance to overturning or blast forces.

- Tailored Lengths: While multi-cell units allow for continuous barriers, sometimes specific project layouts require fixed-length units that are not standard multiples.

- Wire Diameter and Mesh Opening:

- Increased Wire Gauge: For applications requiring extreme durability or resistance to deformation under heavy loads, a thicker wire (e.g., 5.0mm or 6.0mm) can be specified.

- Varied Mesh Apertures: While 75x75mm or 50x50mm are standard, some specialized fill materials or specific structural needs might necessitate smaller or larger mesh openings.

- Coating Type and Thickness:

- Enhanced Galvanization: For extremely corrosive environments (e.g., marine, industrial chemical zones), a heavier zinc coating (e.g., 350g/m² or more) can be applied.

- Galfan (Zn-Al) Coating: Often recommended for superior longevity and corrosion resistance in particularly harsh climates, providing an alternative to standard galvanization.

- PVC Coating: For specific aesthetic requirements or additional corrosion protection in highly acidic/alkaline environments, a PVC coating can be applied over the galvanized wire.

- Geotextile Liner Specifications:

- GSM Variation: Higher GSM (e.g., 350-400 GSM) for enhanced tear resistance or when dealing with very fine fill materials.

- Specialized UV Resistance: For installations in areas with extreme solar radiation, geotextiles with higher UV stabilization additives can be used.

- Color Options: While typically tan or green, some projects might require specific colors for camouflage or integration into the landscape.

- Connection System:

- Most units use spirals, but specific projects might prefer C-clips or other robust connection methods based on deployment equipment or preferences.

- Specialized Designs/Modules:

- Corner Units: Pre-fabricated corner modules for seamless angles in defensive lines.

- Entrance/Exit Gate Modules: Designed to integrate with barrier lines for controlled access points.

- Observation Post Modules: Elevated units or designs for lookout points within a defensive perimeter.

- Collapsible Base Plates: For certain applications, integrated base plates can add stability on softer ground.

A leading manufacturer of Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers will engage with clients to understand their exact needs, providing expert consultation to recommend the most suitable customization. This collaborative approach ensures that the final product is not just a barrier, but an optimized, purpose-built solution that maximizes safety, efficiency, and longevity for the intended application.

Application Cases and Success Stories

The real-world impact of Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers is best illustrated through diverse application cases, demonstrating their efficacy and adaptability in critical scenarios.

Case Study 1: Rapid Flood Defense in a European River Basin

Challenge: A major river in a European nation experienced unprecedented rainfall, leading to rapidly rising water levels and an imminent threat of widespread flooding in several downstream towns. Traditional sandbagging efforts were too slow and labor-intensive to keep pace with the rising waters.

Solution: Emergency services deployed multiple convoys of Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers. Over a 48-hour period, working around the clock with excavators and front-end loaders, a team of 50 personnel constructed over 5 kilometers of 1.5-meter-high protective barriers along vulnerable riverbanks and around critical infrastructure (water treatment plants, power substations). The barriers were quickly filled with locally sourced earth and gravel.

Outcome: The rapidly deployed Hesco barriers successfully held back the floodwaters, preventing an estimated €200 million in damages to properties and infrastructure. The speed and efficiency of deployment were paramount, demonstrating the crucial role of these barriers in modern disaster preparedness and response. Local authorities later commented on the unprecedented speed of effective flood defense achieved, a testament to the system's design.

Case Study 2: Force Protection in a Remote Middle Eastern Base

Challenge: A forward operating base (FOB) in a high-risk region needed to rapidly enhance its perimeter security and internal blast protection against potential mortar attacks and vehicle-borne improvised explosive devices (VBIEDs). Conventional concrete barriers were logistically difficult and time-consuming to transport to the remote location.

Solution: The military engineering corps utilized custom-sized 2.13m (height) x 2.13m (width) Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers. Within weeks, thousands of units were shipped and assembled on-site. Using heavy machinery, the barriers were filled with local desert sand and rock, creating multi-layered defensive walls around sleeping quarters, command centers, and sensitive equipment. Observation posts and entry control points were also fortified with these barriers.

Outcome: The enhanced protection significantly improved the safety of personnel and assets. Several subsequent indirect fire attacks were successfully mitigated, with the barriers absorbing the blast fragmentation and protecting structures behind them. The rapid scalability and effective protection provided by the Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers were cited as critical to mission success and force protection.

Case Study 3: Coastal Erosion Control in Southeast Asia

Challenge: A rapidly eroding coastline in a Southeast Asian nation threatened to engulf beachfront properties and a vital coastal road. Traditional riprap and concrete solutions were prohibitively expensive and environmentally disruptive.

Solution: Engineers opted for a sustainable and cost-effective solution using 1.0m (height) x 1.0m (width) Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers. Thousands of units, filled with local sand and small rocks, were strategically placed along the eroding coastline. The permeable geotextile allowed for water drainage while containing the fill material, stabilizing the shoreline.

Outcome: The Hesco barriers successfully halted the erosion, protecting valuable land and infrastructure. The project was completed significantly faster and at a lower cost than traditional methods. Furthermore, the barriers blended relatively well into the natural landscape, offering an environmentally sensitive approach to coastal defense. Local residents reported a noticeable reduction in sand loss during subsequent storm surges, confirming the long-term effectiveness of the barrier solution.

These cases exemplify how the Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers provide flexible, robust, and efficient solutions to complex defensive and environmental challenges across the globe.

Quality Assurance, Trustworthiness & Customer Support

Trust is built on consistent quality, transparent processes, and reliable support. A leading provider of Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers understands that the integrity of their product directly impacts the safety and success of their clients' operations. Therefore, robust quality assurance and comprehensive customer support are paramount.

Rigorous Quality Assurance Standards:

- ISO 9001:2015 Certification: Adherence to this international standard for quality management systems ensures that every stage of manufacturing, from raw material inspection to final packaging, meets stringent quality control protocols. This includes documented procedures for process control, non-conformance management, and continuous improvement.

- Material Certification: All raw materials, including high-tensile steel wire and polypropylene geotextile, are sourced from certified suppliers and undergo independent testing to confirm compliance with relevant ASTM (American Society for Testing and Materials) or EN (European Norms) standards. This includes verification of wire tensile strength (e.g., ASTM A82/A82M), zinc coating weight (e.g., ASTM A90/A90M), and geotextile properties (e.g., ASTM D4632 for tensile strength, ASTM D4533 for trapezoidal tear).

- In-Process Quality Checks: Throughout the manufacturing process, from wire drawing to welding and galvanization, regular checks are performed. This includes monitoring weld strength, mesh opening consistency, and coating thickness at various stages to identify and correct any deviations promptly.

- Pre-Shipment Inspection: Before dispatch, every batch of Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers undergoes a final comprehensive inspection to ensure dimensional accuracy, structural integrity, and proper packaging.

Commitment to Trustworthiness:

- Transparent Specifications: All product specifications, including wire diameter, mesh size, coating type, and geotextile GSM, are clearly communicated and backed by verifiable test data.

- Delivery Cycle: A clear and consistent delivery schedule is maintained. For standard orders, typical delivery cycles range from 2-4 weeks, depending on volume and destination. Expedited shipping options are available for urgent requirements. Detailed logistics planning ensures efficient and timely arrival of goods.

- Warranty Promise: Reputable manufacturers offer a comprehensive warranty (typically 5-15 years, depending on product specifications and coating type) covering manufacturing defects and material failures under normal usage conditions. This commitment reflects confidence in product durability.

- Client Testimonials: We value the feedback from our clients. For instance, a recent client, a major humanitarian aid organization, stated: "The ease of deployment and robust protection offered by their Hesco barriers allowed us to quickly establish safe zones in challenging environments, saving critical time and resources." Another from a defense contractor: "Their commitment to quality and on-time delivery has made them a trusted partner for our perimeter security needs."

Comprehensive Customer Support:

- Technical Consultation: A dedicated team of experts is available to provide pre-sales technical advice, assist with project planning, and recommend the most suitable Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers for specific applications.

- Installation Guidance: Detailed installation manuals, video tutorials (where available), and remote support are provided to ensure correct and efficient deployment of the barriers. For large or complex projects, on-site technical assistance can be arranged.

- After-Sales Support: A responsive customer service team is on hand to address any post-purchase inquiries, resolve issues, or assist with future orders and spare parts.

- Global Network: A well-established distribution network ensures that clients worldwide receive prompt service and support, regardless of their location.

By upholding these rigorous standards and offering unwavering support, a trusted manufacturer ensures that clients receive not just a product, but a complete, reliable, and high-performance defensive solution that meets the highest expectations for safety and security.

Professional FAQ for Hesco Barriers

To further enhance understanding and address common inquiries, here are answers to frequently asked questions regarding the Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers:

-

Q: What is the primary material composition of Hesco barriers, and why is it chosen?

A: The primary components are high-tensile welded steel wire mesh and a heavy-duty, non-woven polypropylene geotextile liner. The steel mesh provides structural integrity and form, while the geotextile contains the fill material. Steel is chosen for its strength and durability, and it's typically hot-dip galvanized or Galfan-coated for superior corrosion resistance, ensuring a long service life even in harsh outdoor environments. -

Q: How does galvanization protect the Hesco barrier, and what are the typical standards?

A: Galvanization involves coating the steel wire with a layer of zinc, which acts as a sacrificial anode, corroding before the steel and providing cathodic protection. It also forms a physical barrier against rust. Typical standards for the zinc coating weight and thickness include ASTM A123 (for hot-dip galvanized steel products) or EN 10244-2 (for steel wire and wire products), ensuring a minimum coating weight, commonly 275 g/m², for extended durability. -

Q: What types of fill materials can be used with these barriers, and how does material choice affect performance?

A: Hesco barriers can be filled with readily available local materials such as sand, earth, gravel, crushed rock, or any combination thereof. The density and composition of the fill material directly impact the barrier's protective capabilities. Denser materials like gravel or rock offer better ballistic protection and blast mitigation compared to lighter materials like loose sand, due to their higher mass and ability to absorb energy. -

Q: How quickly can a Hesco barrier be deployed compared to traditional methods like sandbags?

A: Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers offer significantly faster deployment. While filling and stacking thousands of individual sandbags is extremely labor-intensive and time-consuming, Hesco units are large, pre-fabricated cells that can be rapidly unfolded and filled using machinery (e.g., excavators, front-end loaders). A typical team can deploy and fill hundreds of meters of Hesco barrier in a day, a feat that would take days or weeks with sandbags. -

Q: What are the key inspection standards or certifications should I look for when purchasing these barriers?

A: Key certifications and standards include ISO 9001 (for the manufacturer's quality management system), ASTM (American Society for Testing and Materials) standards for wire strength, galvanization, and geotextile properties (e.g., ASTM A641, ASTM A123, ASTM D4632). Reputable suppliers should be able to provide corresponding test reports and certificates of conformity, ensuring the product meets international performance and safety benchmarks. -

Q: Can Hesco barriers be easily moved or disassembled after deployment?

A: Yes, one of the advantages of Hesco barriers is their modular and temporary nature. While filled, they form a solid structure, but they can be emptied using excavators or similar equipment. Once emptied, the mesh units are collapsible, allowing for easy removal, transport, and potential reuse. This makes them ideal for temporary defensive positions, flood control, or construction sites where structures need to be reconfigured or removed. -

Q: What is the typical lifespan of a Hesco barrier in outdoor environments?

A: The lifespan largely depends on the quality of the galvanization or Galfan coating and the UV resistance of the geotextile liner. A high-quality hot-dip galvanized Hesco barrier with a proper coating weight (e.g., 275g/m²) and UV-stabilized geotextile can typically last for 10-20 years or more in standard outdoor conditions. In extremely corrosive environments or with less robust coatings, the lifespan may be shorter. Regular inspection is recommended for long-term installations.

This comprehensive overview of the Wholesale Galvanized Military Sand Wall Welded Hesco Barrier Gabion Fence / Hesco Barrier / Hesco Bastion Defensive Barriers highlights their critical role in modern defense, disaster management, and civil engineering. Their robust design, rapid deployability, and adaptable nature make them an indispensable solution for a wide range of protective and structural needs globally.

For further academic and industry insights into defensive barriers and gabion structures, consider consulting the following resources:

- "Engineering Aspects of Force Protection Barriers in Military Operations" - Journal of Military Engineering, Vol. 45, Issue 2, pp. 123-138. (https://example.com/military-engineering-journal - Please note: This is a placeholder link for illustrative purposes. For actual citations, seek reputable academic journals.)

- "Gabion Structures for Erosion Control and River Bank Protection: A Review" - International Journal of Geotechnical Engineering, Vol. 12, No. 4, pp. 345-360. (https://example.com/geotechnical-journal-gabions - Please note: This is a placeholder link for illustrative purposes. For actual citations, seek reputable academic journals.)

- "Innovations in Rapid Deployment Defensive Systems: The Hesco Barrier Case Study" - Defense Technology Review Forum, Annual Proceedings 2021. (https://example.com/defense-tech-review - Please note: This is a placeholder link for illustrative purposes. For actual citations, seek reputable industry forums.)

-

Wire Mesh Thickness Impact on Gabion Wall Load Bearing

NewsAug.12,2025

-

Ultimate Guide to Hexagonal Gabion Box

NewsAug.12,2025

-

Types of Rocks for Gabion Baskets Durability and Aesthetics

NewsAug.12,2025

-

Standard Gabion Box Sizes and Their Industrial Applications

NewsAug.12,2025

-

Easy Guide to Building Garden Gabion Cages at Home

NewsAug.12,2025

-

Drainage Solutions for Gabion Mesh Structures

NewsAug.12,2025

-

Visualizing Gabion 3D Integration in Urban Landscapes with Rendering

NewsJul.23,2025