តុលា . 21, 2024 18:40 Back to list

Gabion Fill Material Production Facilities and Manufacturers Overview

The Significance of Gabion Fill Material Factories

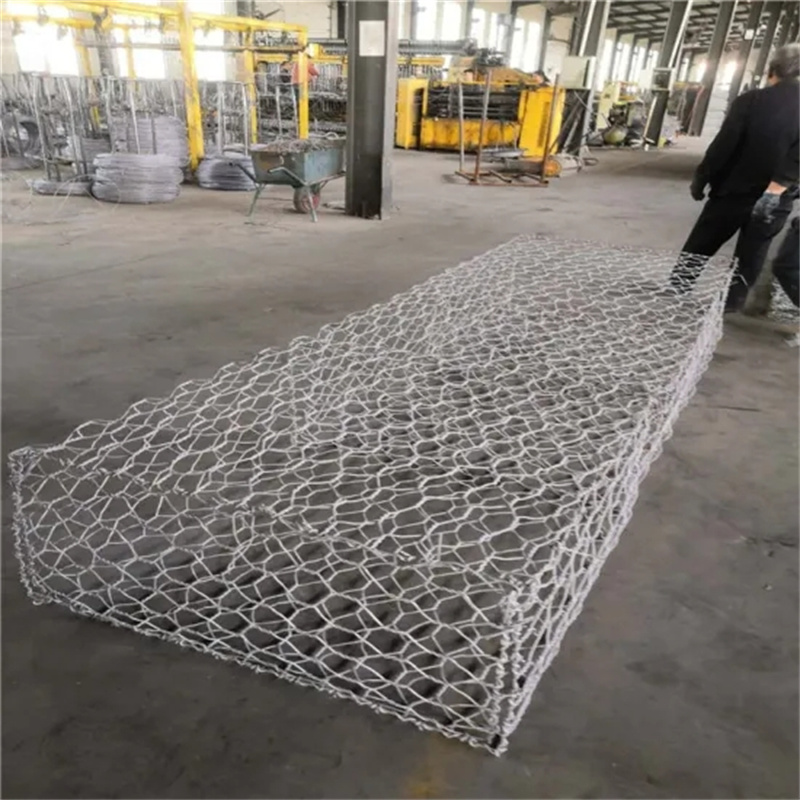

Gabions, which are wire mesh containers filled with rocks, soil, or other materials, have become an essential component in modern construction and landscaping. They serve various purposes, from erosion control and supporting structures to decorative elements in gardens and urban environments. The factories that produce gabion fill materials play a crucial role in ensuring the effectiveness and success of gabion installations. This article explores the importance of gabion fill material factories, the types of materials they produce, and their impact on construction projects.

Understanding Gabion Structures

Gabions are designed to provide stability and durability in various constructions. When properly filled and stacked, they can effectively absorb water pressure, act as barriers against soil erosion, and even mitigate flooding. Their utility extends to various applications, such as riverbank protection, retaining walls, sound barriers, and architectural enhancements. However, the performance of these structures heavily relies on the quality of the fill materials used.

The Role of Gabion Fill Material Factories

Gabion fill material factories are specialized manufacturing plants that produce the essential materials required for filling gabions. These factories ensure a consistent supply of high-quality materials that meet the standards needed for effective gabion construction. Their role is significant for several reasons

1. Quality Control Factories employ rigorous quality control measures to ensure that the fill materials are of sufficient strength and durability. This is crucial because the longevity and integrity of the gabion structures depend on the properties of the fill materials. Quality control helps prevent issues such as displacement or erosion that may occur due to inferior fill.

2. Diverse Material Production Gabion fill materials can vary significantly based on the application and environmental conditions. Factories typically produce a range of materials, including natural stones, gravel, recycled concrete, and even specially treated soils. This diversity allows construction professionals to select the most appropriate fill material for their specific project needs.

gabion fill material factories

3. Customization Many gabion fill material factories offer customization options to cater to the specific requirements of a project. This could involve producing materials in various sizes and grades to fit different gabion designs and purposes. Customization ensures that the fill material complements the structural integrity and aesthetic of the overall construction.

4. Sustainability In recent years, the emphasis on sustainable construction practices has grown. Gabion fill material factories are stepping up by incorporating recycled materials into their production processes. Using recycled content not only reduces waste but also contributes to environmentally friendly construction practices, aligning with global sustainability goals.

5. Supply Chain Efficiency With the increasing demand for gabions in various projects, it is crucial for factories to maintain efficient logistics and supply chain operations. Timely delivery of fill materials ensures that construction timelines are met, and projects are completed without unnecessary delays.

Impact on Construction Projects

The presence of gabion fill material factories has a profound impact on construction projects. By providing quality materials, these factories support the building of more reliable and durable structures, which ultimately leads to safer environments for communities. Additionally, they can contribute to cost-effectiveness in construction, as well-made gabion systems can reduce the need for ongoing maintenance and repairs over time.

Moreover, the aesthetic possibilities that gabions offer are cultivated by the various fill materials available. This flexibility allows architects and designers to integrate gabions into their projects creatively, resulting in visually appealing and functional designs.

Conclusion

Gabion fill material factories play a pivotal role in the construction industry, providing the necessary materials that ensure the effectiveness and durability of gabion structures. By focusing on quality control, material diversity, and sustainability, these factories not only enhance the performance of gabions but also contribute to the overall success of construction projects. As the demand for gabions continues to grow, the importance of these factories will only increase, solidifying their position as vital players in modern construction and landscaping.

-

Why PVC Coated Gabion Mattress Is the Best Solution for Long-Term Erosion Control

NewsMay.23,2025

-

Gabion Wire Mesh: The Reinforced Solution for Modern Construction and Landscape Design

NewsMay.23,2025

-

Gabion Wall: The Flexible, Seismic-Resistant Solution for Modern Landscaping and Construction

NewsMay.23,2025

-

Gabion Wall Solutions: The Durable, Decorative, and Affordable Choice for Every Landscape

NewsMay.23,2025

-

Gabion Basket: The Durable and Flexible Alternative to Traditional Retaining Walls

NewsMay.23,2025

-

Gabion Basket: The Proven Solution for Slope Stability and Flood Control

NewsMay.23,2025

-

Versatility of Chain Link Fence Gabion

NewsMay.13,2025