តុលា . 30, 2024 12:31 Back to list

gabion wire gauge suppliers

Understanding Gabion Wire Gauge and Reliable Suppliers

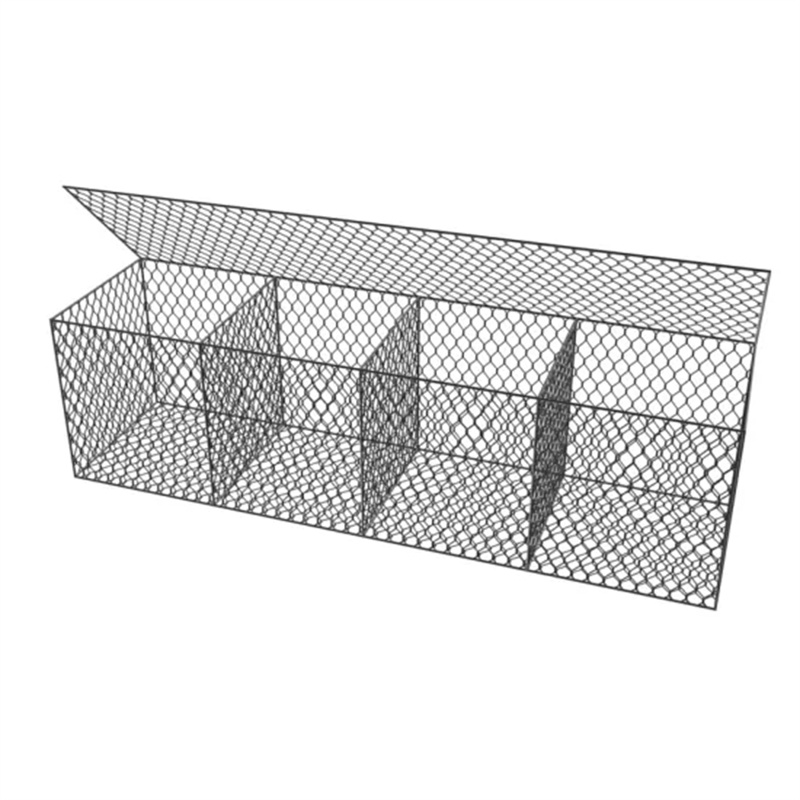

Gabions, which are wire mesh boxes filled with stones or other materials, are widely used in civil engineering for various applications, including retaining walls, riverbank stabilization, and erosion control. One crucial aspect of gabion quality and functionality is the wire gauge used in the construction of the mesh. The wire gauge determines the strength, flexibility, and overall durability of the gabion structures. Therefore, choosing a reliable supplier that provides high-quality gabion wire gauge is essential for ensuring the success of any project involving gabions.

What is Wire Gauge?

Wire gauge refers to the thickness of the wire used in the mesh of gabions. Typically, the gauge is measured in standard wire gauge (SWG), where a lower number indicates a thicker wire. The choice of wire gauge can significantly affect the performance of gabions. For instance, a thicker wire (typically 2.0mm to 5.0mm) is suitable for heavy-duty applications, providing higher tensile strength and resistance to deformation. In contrast, thinner wires may be adequate for lighter, less-stressed applications. Understanding the specific requirements of your project is vital for selecting the appropriate wire gauge.

Importance of Quality Gabion Wire Gauge

The quality of the wire used in gabions is just as critical as its gauge. Quality wire is often coated with materials such as PVC or galvanized to protect against corrosion and enhance longevity. Corrosion-resistant properties are especially important in environments exposed to water or harsh conditions. Low-quality wire may lead to rust and deterioration, compromising the integrity of the gabion structure over time. Therefore, sourcing your materials from reputable suppliers who guarantee high-quality wire is paramount.

gabion wire gauge suppliers

Finding Reliable Suppliers

When looking for gabion wire gauge suppliers, consider a few key factors. Start by checking the supplier’s reputation and customer reviews. Established suppliers with positive feedback often offer reliable products. It’s also vital to inquire about the sourcing of their materials and whether they comply with industry standards.

Additionally, engage with suppliers who provide a variety of wire gauges and coatings, as this flexibility can be advantageous for different project needs. Some suppliers may even offer custom solutions tailored specifically to your requirements, providing added value.

Conclusion

Gabions are a versatile and practical solution for numerous engineering challenges, and the wire gauge used in their structure plays a pivotal role in determining their effectiveness. By understanding the importance of both wire gauge and quality, and by sourcing materials from reputable suppliers, project managers and engineers can enhance the reliability and durability of their gabion installations. Taking the time to choose the right materials will ultimately lead to successful, long-lasting results in any gabion-related project.

-

The Role of Galvanized Gabion Mesh in Riverbank Protection

NewsJun.26,2025

-

The Role of Gabion Basket Raised Bed in Sustainable Gardening

NewsJun.26,2025

-

Quality Assurance of Wire Mesh Gabion Baskets

NewsJun.26,2025

-

Installation Guide for Welded Gabion Box

NewsJun.26,2025

-

How to Choose the Right Gabion Box

NewsJun.26,2025

-

Different Types of Gabion Wire Mesh

NewsJun.26,2025

-

Why PVC Coated Gabion Mattress Is the Best Solution for Long-Term Erosion Control

NewsMay.23,2025