Окт . 21, 2024 15:13 Back to list

Welded Wire Mesh Gabion Production Facility Overview and Benefits

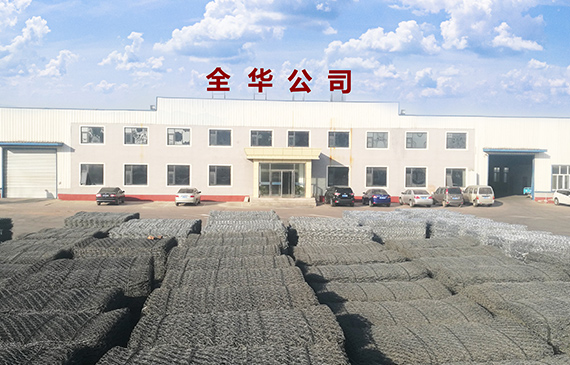

Understanding Welded Wire Mesh Gabion A Look into the Factory Production Process

Welded wire mesh gabions have emerged as a popular choice for various construction and landscaping projects. These versatile structures, made from welded wire mesh, provide both functional and aesthetic benefits. This article explores the production process of welded wire mesh gabions, delving into the factory conditions and technologies that contribute to their quality.

What Are Welded Wire Mesh Gabions?

Gabions are wire mesh cages filled with rock, concrete, or soil to create stable structures. Welded wire mesh gabions, in particular, are constructed from thick steel wires that are welded at intersections. This results in a strong, durable material that can withstand harsh environmental conditions. They are commonly used in retaining walls, erosion control, and decorative landscaping, as well as for flood defense systems.

The Factory Production Process

1. Material Selection The first step in producing welded wire mesh gabions is selecting high-quality steel wire. The wire is often galvanized or coated with PVC to enhance its corrosion resistance, thereby ensuring the longevity of the gabion structures.

2. Welding Process Once the wire is selected, it is fed into automated welding machines. These machines create a grid of welded intersections, forming the mesh. The consistency of the welds is crucial, as it determines the strength of the finished product. Factories employ strict quality control measures to ensure that each weld meets industry standards.

3. Mesh Cutting and Shaping After welding, the mesh is cut to specific dimensions based on customer requirements. The factory can produce gabions of various shapes and sizes, ranging from small baskets to large wall structures. This flexibility allows for a wide range of applications.

welded wire mesh gabion factory

4. Assembly The cut mesh pieces are then assembled into gabion boxes. This is typically done using a combination of manual and automated processes. Each box is formed by folding the mesh into the desired shape and securing the edges with additional wire or connectors. Factories ensure that all boxes are structurally sound and meet design specifications.

5. Surface Treatment To further enhance durability, the assembled gabions undergo surface treatments. Galvanization or PVC coating is applied at this stage to protect against rust and environmental wear. This treatment extends the life of the gabions and keeps them looking new for years.

6. Quality Assurance Each batch of welded wire mesh gabions is subjected to rigorous quality checks. This includes inspecting the welds, the dimensional accuracy of the boxes, and the effectiveness of the surface treatment. Only those that pass all tests are cleared for shipment.

7. Packaging and Distribution Once quality assurance is complete, the gabions are packaged for delivery. Factories use sturdy packaging materials to prevent any damage during transportation. They work closely with logistics partners to ensure timely and efficient delivery to clients worldwide.

Applications and Benefits

Welded wire mesh gabions are used in a myriad of applications. Their strength and versatility make them ideal for construction projects, landscaping, and environmental protection. They can be filled with a variety of materials, allowing for design flexibility. Moreover, their ability to filter water reduces erosion and promotes vegetation in stony areas, making them environmentally friendly.

In conclusion, welded wire mesh gabion factories play a crucial role in producing these essential structures. With a commitment to quality and sustainability, they ensure that welded wire mesh gabions meet industry standards and customer expectations. As the demand for durable and efficient construction materials continues to grow, welded wire mesh gabions remain at the forefront of innovative landscaping and civil engineering solutions.

-

HESCO Gabion Baskets for Coastal Erosion Prevention

NewsAug.22,2025

-

Longevity and Durability of River Rock Gabion Walls

NewsAug.22,2025

-

How to Integrate Gabion 3D Walls in Urban Planning

NewsAug.22,2025

-

Reno Mattress Gabion Applications in Civil Engineering

NewsAug.22,2025

-

How to Install Wire Mesh for Gabion Baskets Properly

NewsAug.22,2025

-

Best Materials for Filling a Chain Link Gabion

NewsAug.22,2025

-

Wire Mesh Thickness Impact on Gabion Wall Load Bearing

NewsAug.12,2025