Nov . 06, 2024 17:58 Back to list

Different Sizes of Gabion Baskets Available from Various Manufacturers and Suppliers

Gabion Basket Sizes and Their Factory Production

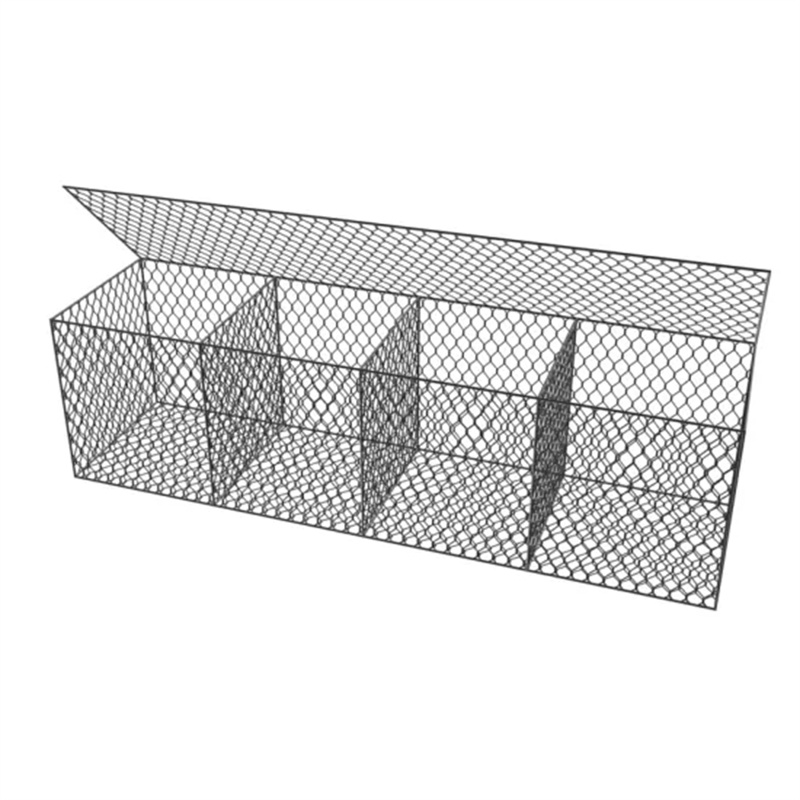

Gabion baskets are versatile and robust structures primarily used in civil engineering, landscaping, and erosion control. These baskets are made from wire mesh filled with stones, gravel, or other materials, and they serve various purposes, including retaining walls, riverbank stabilization, and decorative features. One of the critical factors in the effectiveness of gabion baskets is their size, which can vary significantly depending on their intended application.

Understanding Gabion Basket Sizes

Gabion baskets typically come in standard sizes, but they can also be customized according to specific project requirements. The most commonly used sizes include 1m x 1m x 1m, 1m x 2m x 1m, and 2m x 2m x 0.5m. The dimensions relate to the depth, height, and width, respectively. Smaller baskets are often used for landscaping and decorative purposes, while larger ones are preferred for structural applications where substantial support is needed.

When selecting the size of a gabion basket, factors such as the soil conditions, the load it must bear, and the environmental factors must be taken into account. Increased sizing allows for more significant weight distribution and greater resistance to erosion and shifting, making it crucial in areas prone to heavy rainfall or flooding.

Manufacturing Process

Gabion baskets are produced by specialized factories that follow stringent quality control measures to ensure the durability and resilience of the final product. The manufacturing process typically begins with the selection of high-quality steel wire, which is galvanized or PVC coated to prevent corrosion and extend lifespan. The wire is then woven into a mesh format to create the baskets.

gabion basket sizes factories

Once the wire mesh is prepared, the baskets are formed into the required sizes using automated machinery. This machinery can produce a variety of sizes simultaneously, enabling manufacturers to meet diverse client needs efficiently. After shaping, the gabion baskets undergo a quality assessment where they are tested for structural integrity, resistance to corrosion, and adherence to industry standards.

Customization and Versatility

Modern gabion factories offer options for customization, allowing contractors and consumers to specify sizes beyond the standard offerings. Custom sizes can accommodate specific projects, such as unique landscaping designs or specific engineering requirements. Moreover, the fill material of gabion baskets can also vary, leading to innovative designs that enhance both functionality and aesthetics.

Some manufacturers will even provide additional services, such as filling the gabion baskets with suitable materials, allowing for quicker installation on-site. This adaptability has significantly contributed to the increasing popularity of gabion baskets in various industries, from construction to landscape architecture.

Conclusion

In conclusion, the sizes of gabion baskets are crucial to their effectiveness in various applications, from civil engineering to landscaping. Understanding the standard sizes available and the manufacturing processes employed can help project managers, engineers, and contractors make informed decisions. Additionally, the option for customization enhances the versatility of gabion baskets, ensuring that they can meet the specific demands of each project, thus providing effective solutions for erosion control, stabilization, and decorative purposes. As demand continues to grow, the gabion basket manufacturing industry is poised to innovate further, offering even more size options and bespoke solutions to accommodate the ever-evolving needs of clients and projects worldwide.

-

Visualizing Gabion 3D Integration in Urban Landscapes with Rendering

NewsJul.23,2025

-

The Design and Sustainability of Gabion Wire Mesh Panels

NewsJul.23,2025

-

The Acoustic Performance of Gabion Sound Barriers in Urban Environments

NewsJul.23,2025

-

Mastering the Installation of Galvanized Gabion Structures

NewsJul.23,2025

-

Gabion Boxes: Pioneering Sustainable Infrastructure Across the Globe

NewsJul.23,2025

-

Custom PVC Coated Gabion Boxes for Aesthetic Excellence

NewsJul.23,2025

-

Installation Tips for Gabion Wire Baskets in Erosion Control Projects

NewsJul.21,2025