Dec . 11, 2024 09:34 Back to list

Estimating Costs and Sourcing for Gabion Wall Manufacturing and Installation

Understanding Gabion Wall Estimation An Insight into Factories and Production

Gabion walls are increasingly popular in modern landscaping and civil engineering due to their versatility and sustainability. These walls, constructed from wire mesh cages filled with rocks, stones, or other materials, serve various purposes, such as erosion control, landscaping, and noise reduction. However, when embarking on a gabion wall project, one crucial aspect to consider is the estimation of costs and logistics involved in the production of gabion materials. This article will delve into the details of gabion wall estimation, particularly focusing on the role of factories in the process.

What is a Gabion Wall?

A gabion wall is a structure made of wire mesh containers (gabions) filled with rock or other heavy materials, providing structural integrity and aesthetic appeal. They can be designed to fit various environments, from rugged terrains to urban settings. Besides offering an environmentally friendly alternative to traditional retaining walls, gabion walls allow for excellent drainage, reducing pressure buildup and minimizing the risk of failure.

The Importance of Accurate Estimation

Estimation is a critical step in any construction project, including gabion wall installations. Proper estimation involves evaluating the quantity of materials required, the labor cost, and the overall resources necessary to complete the project. Accurate estimates not only help in budgeting but also ensure that clients receive a realistic timeline for project completion. Misestimation can lead to delays, increased costs, and resource wastage—three scenarios that no project manager wants to encounter.

Role of Factories in Gabion Wall Production

Factories play a vital role in the manufacturing of gabion products. They are responsible for supplying the wire mesh cages that form the framework of gabion walls. The production process involves several key steps

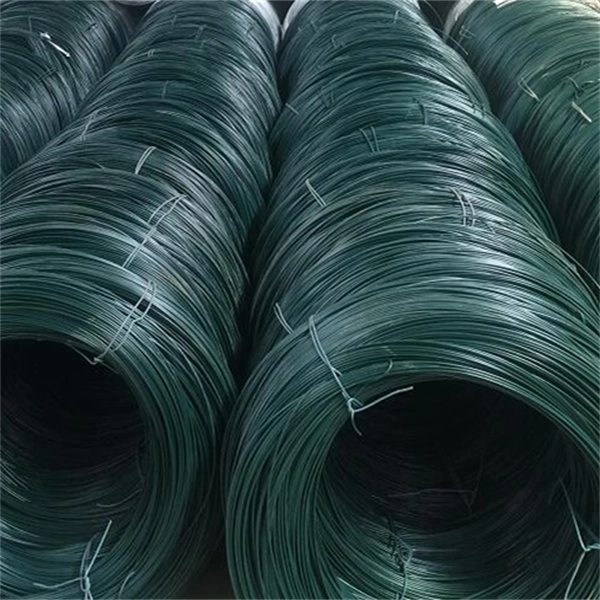

1. Material Selection Factories must choose durable materials that can withstand harsh environmental conditions. Typically, galvanized steel wire is used to prevent corrosion, increasing the lifespan of gabions.

2. Manufacturing Process The manufacturing process includes cutting, bending, and welding wire to create the mesh cages. Factories utilize specialized machinery to ensure precision and efficiency in production.

3. Quality Control Quality control is essential to meet construction standards and regulations. Factories conduct rigorous testing to ensure the mesh’s strength and durability.

gabion wall estimate factories

4. Customization Many projects require customized gabion sizes or shapes. Factories that offer flexible manufacturing processes can cater to specific project needs, whether it’s larger cages for a retaining wall or smaller sizes for landscaping.

5. Logistics and Supply Chain Factories also manage logistics to ensure timely delivery of gabions to construction sites. Efficient supply chain management is crucial to keeping projects on schedule.

Estimating Costs for Gabion Walls

In estimating the costs associated with gabion walls, several factors must be considered. These include

- Material Costs This encompasses the price of wire mesh and the fill material (rock, stone, or other). Bulk purchasing often leads to significant discounts.

- Labor Costs Estimation should factor in the cost of skilled labor required for assembly and installation. Depending on the project’s complexity, labor costs can vary significantly.

- Transportation Costs Costs associated with transporting materials from the factory to the site should not be overlooked. Distance and delivery method can strongly influence logistics expenses.

- Site Preparation Preparing the site for installation, such as excavation and grading, can add to the overall cost. Proper site evaluation is necessary to provide accurate estimations.

- Additional Features If the gabion wall includes additional features like drainage systems or aesthetic enhancements, these should also be factored into the estimate.

Conclusion

Gabion walls are a practical choice for many construction and landscaping projects. Understanding the estimation process and the role of factories in the production of gabion materials is essential for contractors and clients. By focusing on accurate estimation and partnering with reputable factories, stakeholders can ensure the successful and cost-effective completion of gabion wall projects, yielding benefits that last long after construction is finished.

-

Wire Mesh Thickness Impact on Gabion Wall Load Bearing

NewsAug.12,2025

-

Ultimate Guide to Hexagonal Gabion Box

NewsAug.12,2025

-

Types of Rocks for Gabion Baskets Durability and Aesthetics

NewsAug.12,2025

-

Standard Gabion Box Sizes and Their Industrial Applications

NewsAug.12,2025

-

Easy Guide to Building Garden Gabion Cages at Home

NewsAug.12,2025

-

Drainage Solutions for Gabion Mesh Structures

NewsAug.12,2025

-

Visualizing Gabion 3D Integration in Urban Landscapes with Rendering

NewsJul.23,2025