Aug . 11, 2025 01:20 Back to list

Narrow Gabion Baskets Supplier - Factory Direct, Premium Quality

The Strategic Role of a Premier narrow gabion baskets supplier in Modern Infrastructure

In the rapidly evolving landscape of civil engineering and environmental protection, the demand for resilient and sustainable solutions is paramount. Among these, gabion baskets stand out as a versatile and cost-effective choice for various structural and hydraulic applications. Specifically, the need for specialized narrow gabion baskets has surged, driven by complex project requirements such as restricted construction sites, intricate channel linings, and decorative landscape features. A reliable narrow gabion baskets supplier plays a critical role in providing high-quality, precision-engineered products that meet stringent project specifications and contribute to the long-term integrity of infrastructure. This deep dive explores the technical aspects, manufacturing excellence, and strategic advantages offered by leading suppliers in this niche market.

The industry trend indicates a growing preference for modular and adaptable construction materials, making narrow gabions an indispensable component for engineers and contractors. Their inherent flexibility allows for natural settlement without compromising structural integrity, a crucial advantage in unstable soil conditions or seismic zones. Furthermore, their permeable nature facilitates natural drainage, mitigating hydrostatic pressure buildup behind retaining structures and contributing to environmental sustainability. Understanding the nuances of material selection, manufacturing processes, and application benefits is crucial for any procurement specialist or project manager.

Unveiling the Advanced Manufacturing Process of Gabion Terramesh Systems

The production of high-quality gabion terramesh, such as the hot dipped galvanized gabion terramesh, involves a precise, multi-stage manufacturing process designed to ensure durability and performance. It begins with the selection of high-grade steel wire, typically low-carbon steel, which is then drawn to specific diameters, ranging from 2.0 mm to 4.0 mm for gabion mesh and 2.2 mm to 3.2 mm for lacing wire, adhering to international standards like ASTM A641/A975. This wire undergoes a robust surface treatment, most commonly hot-dip galvanization, where it is immersed in molten zinc at approximately 450°C. This process creates a metallurgically bonded zinc coating, providing superior corrosion resistance. For enhanced durability, some products may feature an additional PVC coating (typically 0.5mm thick) over the galvanized wire, offering protection against aggressive environmental conditions and UV radiation.

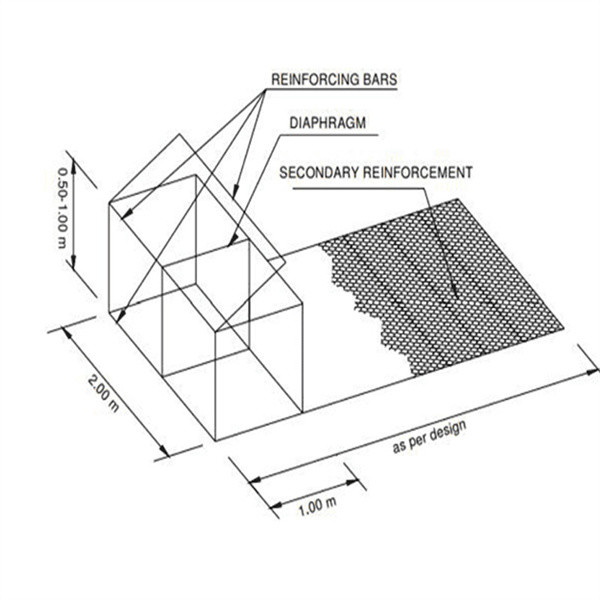

Following galvanization, the wire is machine-woven into a double-twisted hexagonal mesh or welded into a rectangular grid. The double-twist method, a hallmark of traditional gabion manufacturing, ensures that even if a wire breaks, the integrity of the mesh is maintained. Automated machinery forms the mesh into baskets of specified dimensions (e.g., narrow profiles like 1.0x0.5x0.5m or 2.0x0.5x0.5m), complete with diaphragms to prevent deformation when filled. Each finished unit undergoes stringent quality control, including tensile strength tests (e.g., minimum 380-550 N/mm²), wire diameter checks, and coating thickness measurements (e.g., ≥245 g/m² for hot-dip galvanization). This rigorous adherence to standards like ISO 9001 and industry-specific benchmarks ensures that every narrow gabion basket meets the performance requirements for demanding applications in civil engineering, hydraulic works, and environmental remediation.

The lifespan of these hot-dipped galvanized gabion terramesh products is significantly extended due to the anti-corrosion properties, often exceeding 50 years in benign environments and 25 years even in harsh conditions, making them a sustainable choice for long-term projects. Applicable industries predominantly include river training, erosion control, retaining walls, highway embankments, and channel linings where flexibility, permeability, and structural stability are critical.

Technical Parameters & Performance Benchmarks for Narrow Gabion Baskets

When selecting a narrow gabion baskets supplier, understanding the critical technical parameters and their implications for project performance is essential. These parameters define the structural integrity, durability, and suitability of the gabions for specific applications. The following table provides typical specifications for hot-dipped galvanized gabion terramesh, crucial for B2B decision-makers.

| Parameter | Specification Range | Relevant Standard |

|---|---|---|

| Wire Diameter (Mesh) | 2.0 mm - 4.0 mm | ASTM A975, EN 10223-3 |

| Wire Diameter (Selvedge) | 3.0 mm - 4.5 mm (typically 0.5-1.0mm larger than mesh wire) | ASTM A975, EN 10223-3 |

| Mesh Size (Opening) | 60x80 mm, 80x100 mm, 100x120 mm | ASTM A975, EN 10223-3 |

| Zinc Coating Weight | ≥ 245 g/m² (for wire Ø ≥ 2.7mm) | ASTM A90/A641, EN 10244-2 |

| Tensile Strength | 380 - 550 N/mm² (Wire) | ASTM A975, EN 10223-3 |

| PVC Coating Thickness (if applicable) | ≥ 0.5 mm nominal | ASTM D792, EN 10245-2 |

| Typical Narrow Dimensions (L x W x H) | 1.0x0.5x0.5m, 2.0x0.5x0.5m, 3.0x0.5x0.5m, etc. | Custom per project |

These specifications are crucial for ensuring the product's performance in resisting environmental stresses, including corrosion, abrasion, and structural loads. A reputable narrow gabion baskets factory will provide detailed technical datasheets for their products, confirming compliance with these benchmarks and relevant international standards. The right combination of wire gauge, mesh type, and coating ensures optimal strength and longevity for each specific application, whether it's for river bank protection, retaining walls, or intricate landscaping.

Versatile Applications and Strategic Advantages of Narrow Gabion Baskets

The adaptability of narrow gabion baskets makes them invaluable across a spectrum of engineering disciplines. In civil infrastructure, they excel as retaining walls where space is limited, such as roadside embankments or urban flood defenses. Their inherent flexibility allows them to conform to ground settlement without structural failure, a significant advantage over rigid concrete structures. For hydraulic engineering, narrow gabions are ideal for channel lining, weir construction, and scour protection, providing permeable structures that dissipate energy and promote natural drainage, thus preventing hydrostatic pressure buildup.

Beyond their structural merits, narrow gabions offer distinct environmental and economic benefits. Their permeable nature promotes ecological integration, allowing vegetation to grow through the structure, enhancing aesthetic appeal and providing habitat. From an economic standpoint, the fill material, often locally sourced stone, significantly reduces transportation costs and carbon footprint compared to pre-fabricated concrete units. The ease of installation, requiring less specialized equipment and labor, further contributes to cost efficiencies, making them an attractive solution for projects requiring sustainable and cost-effective earth retention or erosion control. This combination of technical efficacy, environmental compatibility, and economic viability cements their position as a preferred choice for discerning engineers and project developers, making the selection of an experienced narrow gabion baskets supplier even more critical.

Their long-term performance, particularly when using hot-dipped galvanized or PVC-coated wire, ensures a lifespan that often exceeds the design life of many projects, providing excellent return on investment. This durability, coupled with their structural resilience, positions them as a superior choice for projects demanding both engineering integrity and environmental sensitivity.

Selecting a Leading Narrow Gabion Baskets Supplier: Key Considerations

Choosing the right narrow gabion baskets supplier is a strategic decision that impacts project timelines, budget, and structural integrity. A truly authoritative supplier distinguishes itself through several key attributes. Firstly, look for comprehensive quality certifications, such as ISO 9001:2015, which indicates a robust quality management system covering design, production, and supply. Adherence to international product standards like ASTM A975 (for wire mesh gabions) and EN 10223-3 (for steel wire mesh for gabions) is non-negotiable, ensuring product reliability and compliance with engineering specifications.

Secondly, assess their manufacturing capabilities. A top-tier narrow gabion baskets factory will possess advanced automated production lines, ensuring consistent mesh size, wire diameter, and galvanization thickness. Inquire about their capacity for custom solutions, as unique project demands often require tailored basket dimensions or specialized coatings. Experience matters; a supplier with a proven track record of successfully supplying gabions for diverse projects, from large-scale river protection to intricate landscaping, demonstrates reliability and expertise. Review their client portfolios and case studies to gauge their project experience.

Finally, consider their post-sales support, including technical assistance, delivery logistics, and warranty provisions. A supplier that offers comprehensive customer support, timely delivery schedules, and clear warranty terms instills confidence and mitigates project risks. Partnerships with renowned engineering firms or government agencies can also be an indicator of their authoritative standing within the industry. By prioritizing these factors, procurement teams can secure a partnership that guarantees high-quality products and reliable service.

Ensuring Trustworthiness: Certifications, Warranties, and Customer Support

For B2B clients, trustworthiness is built on a foundation of verifiable standards and reliable support. A reputable narrow gabion baskets supplier or one of the leading narrow gabion baskets factories will readily provide documentation of their certifications, such as ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System), underscoring their commitment to consistent quality and responsible manufacturing. Furthermore, compliance with specific product standards like ASTM A975 for the double-twisted hexagonal mesh gabions, or EN 10244-2 for zinc coating, is crucial evidence of product conformity and reliability.

Delivery schedules and logistics transparency are also key indicators of trustworthiness. A professional supplier will provide clear estimates for production lead times (e.g., 2-4 weeks for standard orders, depending on volume) and efficient shipping solutions, whether by sea, rail, or road, to ensure timely project execution. Comprehensive warranty statements, typically covering manufacturing defects and material integrity for a specified period (e.g., 5-10 years on manufacturing defects, 25+ years on coating performance), offer peace of mind and protect investments.

Finally, dedicated customer support, including technical consultations, installation guidance, and responsive post-sales service, is a hallmark of a trustworthy partner. This holistic approach ensures that from initial inquiry to project completion, clients receive the necessary expertise and assistance, reinforcing the supplier's commitment to long-term partnerships rather than just transactions. Evaluating these elements collectively empowers businesses to select a narrow gabion baskets supplier that not only delivers quality products but also provides unwavering support.

Frequently Asked Questions (FAQ) about Narrow Gabion Baskets

-

Q1: What are the primary advantages of narrow gabion baskets over traditional retaining wall solutions?

Narrow gabion baskets offer superior flexibility, allowing them to tolerate differential settlement without cracking, unlike rigid concrete. They are permeable, preventing hydrostatic pressure buildup and promoting natural drainage. Their modular design facilitates easier installation, often utilizing local fill materials, reducing construction time and costs. Furthermore, they are environmentally friendly, blending with natural landscapes and supporting vegetation growth.

-

Q2: How does hot-dip galvanization enhance the lifespan of gabion baskets?

Hot-dip galvanization provides a robust, metallurgically bonded zinc coating that acts as a sacrificial layer, protecting the steel wire from corrosion. This process delivers superior durability compared to electro-galvanization, significantly extending the service life of gabion baskets to 50 years or more in non-aggressive environments, and at least 25 years even in harsh coastal or polluted industrial settings.

-

Q3: Can narrow gabion baskets be customized for specific project requirements?

Absolutely. A professional narrow gabion baskets supplier specializes in providing customized solutions. This includes variations in dimensions (length, width, height), wire diameters, mesh sizes, and coating types (e.g., PVC coating over galvanization for extreme environments). Custom orders ensure that the gabions perfectly integrate with the design and structural demands of unique projects.

-

Q4: What are the typical delivery timelines for large orders of gabion baskets?

Delivery timelines can vary based on order volume, customization requirements, and current production schedules. Generally, for standard large orders, a reliable narrow gabion baskets factory can fulfill and ship within 2 to 4 weeks after order confirmation. Expedited shipping options are often available for urgent projects, and it's always best to discuss specific timelines with your chosen supplier.

References

- ASTM A975/A975M - 19, Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With PVC Coating).

- ISO 9001:2015, Quality management systems — Requirements.

- EN 10223-3: Steel wire and wire products for fencing and netting. Hexagonal steel wire netting for civil engineering purposes (gabions).

- Maccaferri: Gabions and Retaining Structures - Technical Information.

-

Visualizing Gabion 3D Integration in Urban Landscapes with Rendering

NewsJul.23,2025

-

The Design and Sustainability of Gabion Wire Mesh Panels

NewsJul.23,2025

-

The Acoustic Performance of Gabion Sound Barriers in Urban Environments

NewsJul.23,2025

-

Mastering the Installation of Galvanized Gabion Structures

NewsJul.23,2025

-

Gabion Boxes: Pioneering Sustainable Infrastructure Across the Globe

NewsJul.23,2025

-

Custom PVC Coated Gabion Boxes for Aesthetic Excellence

NewsJul.23,2025

-

Installation Tips for Gabion Wire Baskets in Erosion Control Projects

NewsJul.21,2025