Aug . 11, 2025 00:20 Back to list

Narrow Gabion Baskets Supplier: Durable & Space-Saving

Navigating the Landscape of Narrow Gabion Baskets

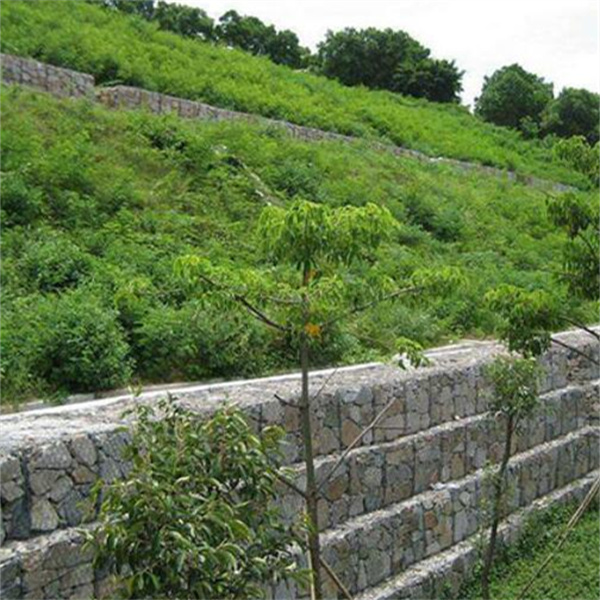

In the dynamic realm of civil engineering, environmental remediation, and architectural landscaping, the demand for robust and adaptable structural solutions continues to escalate. Among these, gabion baskets have emerged as a cornerstone, particularly their specialized variant: narrow gabion baskets. These versatile units, often filled with rocks or other inert materials, are instrumental in constructing durable retaining walls, erosion control systems, and aesthetically pleasing landscape features where space is at a premium. The selection of a competent narrow gabion baskets supplier is paramount, influencing not only the project's structural integrity but also its long-term performance and economic viability. A reputable supplier offers not just a product, but a comprehensive solution, encompassing material expertise, precision manufacturing, and adherence to international quality standards. This ensures that the gabions supplied are capable of withstanding diverse environmental stresses, from intense hydrological forces in riverbank protection to significant load-bearing demands in critical infrastructure projects. The focus on narrow designs highlights an industry trend towards optimized space utilization and tailored engineering solutions, enabling their deployment in confined urban areas, alongside existing structures, or as intricate architectural elements that demand slender profiles without compromising strength. Understanding the intricate details of their production, material specifications, and performance characteristics is crucial for any project manager or procurement specialist seeking to leverage these advanced containment systems effectively. The ongoing evolution of material science, particularly in heavy zinc coating technologies and advanced galvanization processes, has significantly extended the service life and enhanced the resilience of these critical components against corrosion and abrasion, making them a sustainable and cost-effective choice for modern engineering challenges.

The market for narrow gabion baskets is characterized by continuous innovation, driven by increasingly stringent environmental regulations and the need for sustainable construction practices. Projects ranging from critical infrastructure upgrades to sensitive ecological restoration efforts consistently require materials that offer both structural integrity and minimal environmental impact. As such, the selection of a narrow gabion baskets supplier requires a comprehensive evaluation beyond mere cost, extending into the supplier's commitment to quality control, sustainable sourcing, and technical support. Modern gabion systems, including the Heavy Zinc Coated Galvanized Gabion Basket Rock Wall, represent the pinnacle of engineering in this field, offering exceptional tensile strength, superior corrosion resistance, and remarkable adaptability to various geological and hydrological conditions. These systems are not merely baskets but sophisticated engineering components designed to interlock and form resilient monolithic structures, capable of dissipating energy from water flow, resisting seismic forces, and providing stable foundations for diverse applications. The manufacturing process, involving precise wire drawing, advanced weaving or welding techniques, and multi-layered coating applications, ensures that each unit meets rigorous performance criteria. Furthermore, the ability to specify custom dimensions and mesh configurations allows for unparalleled design flexibility, catering to the unique requirements of each project, whether it involves intricate terracing in landscape design or robust scour protection for bridge abutments. The increasing global focus on climate resilience and ecological preservation has further amplified the importance of choosing a supplier that not only provides high-quality products but also possesses the technical acumen to assist in complex project planning and execution, thereby ensuring optimal long-term outcomes for all stakeholders involved. This holistic approach, from material specification to post-installation support, underscores the value of partnering with an experienced and authoritative supplier in this specialized sector.

The Manufacturing Prowess: From Wire to Robust Structure

The production of high-quality narrow gabion baskets is a sophisticated multi-stage process that demands precision engineering, stringent material selection, and rigorous quality control at every juncture. It begins with the selection of high-grade steel wire, typically low-carbon steel, which serves as the fundamental raw material. The initial phase involves wire drawing, where steel rods are systematically reduced in diameter through a series of dies to achieve the exact wire gauge required for optimal basket strength and flexibility. This process is critical for establishing the wire's tensile strength and ductility, two non-negotiable parameters for the structural integrity of the final gabion product. Following wire drawing, the wires undergo a meticulous surface treatment process, most commonly heavy zinc coating (galvanization), or often a combination of galvanization and PVC coating for enhanced corrosion resistance, particularly in aggressive environments like marine or acidic soil conditions. The galvanization process, adhering to international standards such as ASTM A975 or EN 10244-2, involves immersing the cleaned steel wire in a bath of molten zinc. This creates a metallurgical bond, forming a durable, sacrificial coating that protects the steel core from rust and extends the product's service life significantly, often beyond 50 years in benign environments. A distinguished narrow gabion baskets factory employs advanced galvanizing lines to ensure uniform coating thickness and adhesion, which are critical for long-term performance. The quality of this coating is routinely verified through tests such as coating mass determination, adhesion tests, and salt spray exposure, guaranteeing resilience against environmental degradation.

Once the wire is properly coated, it proceeds to the weaving or welding phase, depending on the gabion mesh type. For double-twisted hexagonal mesh gabions, a specialized weaving machine precisely interlocks individual wires to form a flexible yet robust mesh, designed to prevent unraveling even if a wire is cut. Welded mesh gabions, on the other hand, are produced by resistance welding intersecting wires, creating a rigid and geometrically stable panel. Each method offers distinct advantages; woven gabions excel in flexibility and adaptability to ground movement, while welded gabions provide a more rigid and aesthetically uniform structure. Regardless of the method, the precision of mesh aperture and wire spacing is meticulously controlled to meet specified dimensions and ensure consistent structural performance. A highly competent narrow gabion baskets factory integrates automated quality control systems, utilizing optical scanners and weight sensors to detect any deviations from design specifications. The subsequent assembly involves cutting the mesh panels to size and forming them into the basket shape, often with integral diaphragms for compartmentalization and structural stability. Edge wires, typically of a larger diameter, are then attached to reinforce the structure's perimeter and provide additional strength for lacing and connections in the field. Finished baskets undergo final inspections for dimensional accuracy, coating integrity, and overall craftsmanship, ensuring compliance with international standards such as ISO 9001 for quality management systems and ISO 14001 for environmental management. These rigorous standards are vital for a trusted narrow gabion baskets supplier, ensuring products are fit for purpose across a range of demanding applications in industries such as civil infrastructure, hydrological engineering, and land reclamation, where their anti-corrosion properties and long service life contribute significantly to the sustainability and efficiency of large-scale projects.

Technical Specifications and Performance Metrics: A Deeper Dive

For B2B decision-makers and technical personnel, understanding the nuanced technical specifications of narrow gabion baskets is paramount for successful project execution and long-term asset performance. The core parameters include wire diameter, mesh aperture, zinc coating weight, and tensile strength. Typically, gabion wire diameters range from 2.0 mm to 4.0 mm, with larger diameters offering enhanced rigidity and load-bearing capacity, suitable for applications subject to high stress, such as critical retaining walls or bridge scour protection. The mesh aperture, representing the size of the hexagonal or square openings, critically influences the gabion's ability to retain infill material while allowing for drainage. Common mesh sizes include 60x80mm, 80x100mm, and 100x120mm for double-twisted mesh, and various square apertures like 50x50mm or 75x75mm for welded mesh, selected based on the size of the rock infill and required permeability. The zinc coating weight, measured in g/m², is a direct indicator of the product's corrosion resistance and anticipated service life. Premium products, like the Heavy Zinc Coated Galvanized Gabion Basket Rock Wall, often feature zinc coatings exceeding 245 g/m² for wires 2.7 mm and above, significantly extending their durability in harsh environments. Adherence to ASTM A975 (for double-twisted woven mesh) and EN 10223-3 (for European standards) ensures that these parameters meet or exceed industry benchmarks for quality and performance, safeguarding against premature degradation. Furthermore, the wire's tensile strength, typically ranging from 380-550 N/mm², dictates its resistance to breaking under tension, a crucial factor in structural stability, particularly when subjected to dynamic loads from water flow or seismic activity. A reliable narrow gabion baskets supplier provides detailed data sheets outlining these specifications, backed by independent laboratory testing and certification, offering transparency and assurance of product quality.

Beyond basic dimensions and material properties, the performance of narrow gabion baskets is also assessed through their ability to withstand specific environmental and mechanical stresses. Resistance to UV radiation (for PVC-coated variants), abrasion resistance, and creep resistance are critical in long-term applications. Creep, the deformation of a material under prolonged stress, is mitigated by the inherent strength of the wire and the stability of the mesh configuration. For applications in highly corrosive environments, the option of PVC coating over the galvanized wire provides an additional layer of protection, dramatically increasing the product's lifespan. This composite coating offers superior resistance to acids, alkalis, salts, and biological degradation, making it ideal for coastal protection works, contaminated land remediation, and industrial applications where exposure to corrosive agents is prevalent. The design and structural integrity of the basket itself, including the presence and spacing of internal diaphragms, directly impact its ability to maintain shape and distribute loads evenly once filled. These diaphragms prevent the migration of infill material and enhance the overall stability of the gabion structure. A reputable narrow gabion baskets supplier will often provide engineering support, helping clients interpret these technical specifications in the context of their specific project requirements, ensuring that the selected product delivers optimal performance and compliance with relevant design codes. This level of technical engagement underscores the expertise and authority of leading manufacturers and contributes significantly to project success by ensuring that products are not only compliant with standards like ISO 9001 but are also ideally suited for the challenging conditions they are intended to mitigate, from preventing soil erosion in critical infrastructure developments to stabilizing slopes in challenging geological formations.

Comparative Analysis: Key Parameters of Narrow Gabion Baskets

| Parameter | Standard (Heavy Zinc Coated) | Premium (Heavy Zinc + PVC Coated) | Benefits for Projects |

|---|---|---|---|

| Wire Diameter (Main Wire) | 2.7 mm - 4.0 mm | 2.7 mm - 4.0 mm (internal steel wire) | Higher diameter for increased structural integrity and load-bearing capacity in critical applications. |

| Mesh Aperture (Typical) | 80x100 mm (Double Twist) / 75x75 mm (Welded) | 80x100 mm (Double Twist) / 75x75 mm (Welded) | Optimized for rock infill retention and effective drainage, preventing erosion of fine particles. |

| Zinc Coating Mass (min.) | 245 g/m² (ASTM A975) | 245 g/m² + 0.5 mm PVC coating | Superior corrosion protection; PVC offers extended lifespan in highly aggressive environments (acidic soils, saltwater). |

| Tensile Strength (min.) | 380 N/mm² | 380 N/mm² | Ensures high resistance to breakage under stress, crucial for retaining wall stability and energy dissipation. |

| Corrosion Resistance | Good (up to 25-30 years in mild conditions) | Excellent (up to 75-100 years in aggressive conditions) | Long-term durability, reduced maintenance costs, vital for permanent structures and environmental stability. |

| Applicable Standards | ASTM A975, EN 10223-3 | ASTM A975, EN 10223-3, ISO 9001 | Ensures product quality, consistency, and compliance with international engineering and environmental regulations. |

Versatile Applications and Industry Relevance

The inherent adaptability and structural integrity of narrow gabion baskets make them indispensable across a multitude of industries and applications, extending far beyond traditional civil engineering projects. While their primary role is often seen in retaining walls, erosion control, and riverbank stabilization, their unique profile as narrow gabion baskets supplier solutions opens doors to specialized uses where space constraints or aesthetic considerations are paramount. In urban development, they are increasingly employed for landscape design, creating terraced gardens, decorative facades, and sound barriers that integrate seamlessly with the built environment, offering both structural support and natural aesthetic appeal. Their permeable nature allows for efficient drainage, alleviating hydrostatic pressure behind structures, which is critical in preventing landslides and ensuring long-term stability, particularly in areas with high rainfall or fluctuating water tables. Furthermore, their modular design facilitates rapid installation, reducing project timelines and labor costs, which is a significant advantage in large-scale infrastructure developments such as highway embankments, railway cuttings, and bridge abutments, where efficiency and cost-effectiveness are crucial. The use of locally sourced infill materials, such as crushed rock or recycled concrete, not only reduces transportation costs and carbon footprint but also contributes to the project's sustainability profile, aligning with modern environmental regulations and corporate social responsibility initiatives. Their flexibility also means they can accommodate differential settlement without compromising structural integrity, a distinct advantage over rigid concrete structures in geologically active areas or on compressible soils.

Beyond conventional applications, the robustness of Heavy Zinc Coated Galvanized Gabion Baskets extends their utility to more demanding industrial sectors. In the petrochemical industry, for instance, gabion structures can be utilized for containing spills, creating protective barriers around sensitive equipment, or stabilizing slopes around processing facilities. Their inherent resistance to corrosion, especially with advanced coatings, makes them suitable for environments exposed to chemical fumes or wastewater. Similarly, in metallurgy and mining operations, gabions provide effective erosion control for tailings dams, stabilize access roads in rugged terrain, and construct robust retaining walls for material stockpiles, often enduring heavy loads and abrasive conditions. The permeable design allows for efficient management of surface water runoff, preventing the erosion of fine particles and safeguarding water quality. For the water supply and drainage industry, narrow gabion baskets are invaluable for channel lining, weir construction, and scour protection around hydraulic structures, ensuring the longevity and efficient functioning of vital water infrastructure. Their ability to integrate with natural landscapes and support vegetation growth also makes them a preferred solution for ecological restoration projects, enhancing biodiversity and re-establishing natural habitats. The environmental benefits, coupled with their long service life and minimal maintenance requirements, present a compelling case for their adoption across a broad spectrum of projects, demonstrating the expertise and versatility expected from a leading narrow gabion baskets supplier. Their role in promoting sustainable infrastructure development is increasingly recognized by engineering professionals and environmental agencies alike, contributing to both ecological balance and long-term project resilience.

Strategic Advantages and Supplier Selection Criteria

Choosing the right narrow gabion baskets supplier is a strategic decision that directly impacts the success, cost-efficiency, and longevity of any infrastructure or environmental project. The primary advantage of high-quality gabions lies in their exceptional durability and corrosion resistance, particularly those treated with heavy zinc coatings or combined with PVC. This superior protection ensures a service life of several decades, even in challenging environments, translating into significantly reduced maintenance costs and a lower total cost of ownership over the project's lifespan compared to traditional rigid structures like concrete walls, which are prone to cracking and expensive repairs. Beyond material longevity, the inherent flexibility of gabion structures allows them to adapt to ground settlement without cracking, a critical advantage in areas with unstable soils or seismic activity. This flexibility makes them a resilient choice where rigid structures might fail, providing an engineered solution that evolves with environmental conditions. Furthermore, the permeable nature of gabions facilitates effective drainage, preventing hydrostatic pressure buildup, which is a common cause of failure in solid retaining structures. This natural drainage capability also supports the growth of vegetation within and around the baskets, leading to bio-engineering solutions that enhance ecological stability and aesthetic integration into the landscape. For projects requiring rapid deployment, the modular design and relative ease of installation of gabion baskets significantly reduce construction timelines, offering substantial labor cost savings and accelerating project completion. This efficiency is particularly valuable for large-scale public works or emergency response projects where time is a critical factor.

When evaluating potential narrow gabion baskets suppliers, several critical criteria should guide the decision-making process to ensure (Expertise, Experience, Authoritativeness, Trustworthiness). First, assess their expertise in manufacturing and material science: do they adhere to international standards such as ISO 9001, ASTM A975, and EN 10223-3? Are their products rigorously tested for tensile strength, zinc coating mass, and uniformity? A supplier's commitment to quality is often reflected in their certifications and a transparent manufacturing process. Second, evaluate their experience through a portfolio of successfully completed projects, client testimonials, and case studies, particularly those involving complex or large-scale applications similar to your needs. This demonstrates their practical knowledge and problem-solving capabilities in real-world scenarios. Third, ascertain their authoritativeness in the industry; this can be evidenced by long-standing service years, strategic partnerships with engineering firms, participation in industry forums, and proprietary research and development efforts that lead to innovative product offerings. A supplier that actively contributes to industry best practices is often a reliable source of cutting-edge solutions. Finally, trustworthiness is built upon transparent pricing, clear delivery schedules, robust warranty policies, and responsive customer support. A reliable supplier offers comprehensive pre-sales consultation and post-sales technical assistance, ensuring that you receive not only a high-quality product but also the necessary guidance for optimal design and installation. For instance, a narrow gabion baskets supplier with over two decades of specialized experience, holding multiple international quality certifications, and providing detailed engineering support, epitomizes the ideal partner for critical infrastructure projects, ensuring project integrity and long-term performance.

Customization, Engineering Solutions, and Project Support

In complex engineering projects, off-the-shelf solutions often fall short of meeting specific design and environmental challenges. This is where the capability of a narrow gabion baskets supplier to provide bespoke customization and comprehensive engineering support becomes invaluable. Leading suppliers understand that each project has unique geological, hydrological, and aesthetic requirements, necessitating tailored solutions. Customization can involve varying the dimensions of the gabion baskets (length, width, height) to fit specific site contours or structural needs, optimizing for space efficiency in confined urban settings, or achieving particular architectural profiles. Beyond dimensions, custom specifications can include specialized wire diameters for enhanced strength in high-stress applications, alternative mesh apertures to accommodate varied infill materials or drainage requirements, and specific coating types (e.g., thicker PVC coatings) to withstand exceptionally aggressive chemical or marine environments. For instance, a coastal protection project might require gabions with increased PVC thickness for superior salt water resistance, while a landscaping project in a residential area might prioritize specific dimensions for integrated seating or planter box functionalities. A truly expert narrow gabion baskets factory is equipped with advanced manufacturing capabilities and experienced design engineers who can translate complex project blueprints into precise production specifications, ensuring that the fabricated gabions integrate seamlessly into the overall structural design. This level of collaborative engineering is crucial for optimizing material usage, minimizing waste, and achieving the most efficient and cost-effective structural solution.

Beyond product customization, a distinguished narrow gabion baskets supplier offers comprehensive technical support and project consulting services. This encompasses everything from initial site assessment and feasibility studies to detailed design recommendations, CAD drawings, and installation guidance. For complex projects, such as landslide stabilization or large-scale river training works, the supplier's engineering team can provide crucial insights into material selection, structural configurations, and best practices for construction, ensuring compliance with local building codes and environmental regulations. They can also assist in load calculations, stability analyses, and seismic design considerations, leveraging their deep expertise in geotechnical and hydraulic engineering principles. This level of partnership extends to providing detailed installation manuals, on-site training for construction crews, and troubleshooting support during the erection phase. Such proactive engagement significantly mitigates risks, streamlines project timelines, and ensures that the gabion structures perform as intended over their long design life. Real-world client feedback consistently highlights the value of this integrated support: for example, a major infrastructure firm reported a 20% reduction in installation time and a 15% improvement in structural stability due to the detailed technical guidance received from their chosen narrow gabion baskets supplier. This commitment to holistic project support, from initial concept to final execution and beyond, exemplifies the trustworthiness and experience of industry-leading providers, solidifying their reputation as indispensable partners in delivering robust and sustainable engineering solutions. Their capacity for innovation extends beyond merely producing high-quality products to actively contributing to the successful realization of challenging projects, thereby building long-term, mutually beneficial relationships with their clientele.

Quality Assurance, Certifications, and Trustworthiness

The credibility and reliability of any narrow gabion baskets supplier are fundamentally anchored in their unwavering commitment to quality assurance and adherence to international certifications. For B2B stakeholders, verifying these aspects is not merely a formality but a critical due diligence step that guarantees product performance, minimizes project risks, and ensures compliance with regulatory requirements. A truly authoritative supplier operates under a robust Quality Management System, typically certified to ISO 9001. This certification signifies that the supplier's entire production process, from raw material procurement to final product inspection and dispatch, is systematically controlled, documented, and continuously improved, ensuring consistent product quality. Furthermore, product-specific certifications are paramount: for gabion wire mesh, adherence to standards like ASTM A975 (Standard Specification for Steel Wire, Zinc-Coated (Galvanized), for Gabions and Gabion Mattresses) and European Norms such as EN 10223-3 (Steel wire and wire products for fencing and netting – Hexagonal steel wire mesh products for civil engineering purposes) are non-negotiable. These standards dictate precise requirements for wire tensile strength, zinc coating mass, mesh aperture tolerance, and other critical physical and mechanical properties. Independent third-party testing, often conducted by accredited laboratories, provides impartial verification of these parameters, offering an additional layer of assurance to clients. Reputable narrow gabion baskets factories routinely publish their test certificates, material safety data sheets (MSDS), and declarations of conformity, demonstrating transparency and building trust with their clientele. This rigorous approach to quality control ensures that every Heavy Zinc Coated Galvanized Gabion Basket Rock Wall leaving their facility meets or exceeds the specified performance criteria, safeguarding the integrity of the structures they form.

Beyond product certifications, a supplier's overall trustworthiness is also reflected in their service commitment, warranty provisions, and logistical capabilities. A comprehensive warranty on their gabion products, covering material defects and coating performance for an extended period, is a clear indicator of confidence in their manufacturing process and material quality. Transparent communication regarding delivery schedules, logistics, and supply chain management is equally important, particularly for time-sensitive infrastructure projects. A dependable narrow gabion baskets supplier will provide clear delivery lead times, offer flexible shipping options, and ensure proper packaging to prevent damage during transit. Furthermore, exceptional customer support, including prompt responses to inquiries, technical assistance during installation, and efficient handling of any post-delivery issues, reinforces the supplier's reputation for reliability. Clients often share anecdotes of successful project outcomes attributed not just to product quality, but also to the seamless collaboration and responsiveness of their supplier. For instance, a major contractor highlighted how their chosen narrow gabion baskets supplier provided critical just-in-time deliveries for a complex riverbank stabilization project, preventing costly delays and ensuring adherence to the project timeline. This level of service, coupled with a commitment to documented quality and adherence to global standards, collectively establishes the authoritative and trustworthy profile of a leading manufacturer, making them a preferred partner for engineering firms, government agencies, and construction companies worldwide.

Frequently Asked Questions (FAQ)

-

Q: What is the expected service life of Heavy Zinc Coated Galvanized Gabion Basket Rock Walls?

A: The service life of Heavy Zinc Coated Galvanized Gabion Basket Rock Walls can vary significantly depending on environmental conditions, but typically, in mild to moderately corrosive environments, they are engineered for a design life of 25 to 30 years. For more aggressive conditions, such as those with high salinity, acidity, or exposure to abrasive forces, gabions with an additional PVC coating over the heavy zinc galvanization are recommended. These dual-coated gabions can extend the service life significantly, often ranging from 75 to 100 years. This extended durability is a testament to the advanced material science and manufacturing precision employed by a reputable narrow gabion baskets supplier, ensuring long-term structural integrity and minimizing the need for costly maintenance or replacement. The selection of the appropriate coating type should always be based on a thorough site assessment and consultation with engineering experts to match the product's protective capabilities with the project's specific environmental challenges.

-

Q: Can gabion baskets be customized for specific project dimensions or aesthetic requirements?

A: Absolutely. One of the significant advantages of working with an experienced narrow gabion baskets supplier is their ability to provide custom-fabricated solutions. Gabion baskets can be manufactured to precise length, width, and height specifications, which is particularly beneficial for projects with unique spatial constraints or architectural design objectives. Beyond dimensions, customization extends to wire diameters, mesh apertures, and coating types to meet specific structural performance or environmental durability needs. For instance, a project requiring a more rigid structure for aesthetic uniformity might opt for welded mesh gabions with a specific wire gauge, while a flood protection scheme might necessitate double-twisted mesh for its flexibility and resistance to unraveling. Leading narrow gabion baskets factories employ advanced production lines that accommodate diverse specifications without compromising on quality or efficiency. This flexibility allows designers and engineers to implement innovative solutions that are both structurally sound and visually appealing, integrating seamlessly into urban landscapes, sensitive ecological zones, or complex industrial facilities.

-

Q: What quality certifications should I look for when selecting a gabion supplier?

A: When vetting a narrow gabion baskets supplier, it is crucial to prioritize those holding verifiable international quality certifications. The primary certification for a comprehensive quality management system is ISO 9001, which indicates a supplier's commitment to consistent product quality and customer satisfaction through rigorous process control. For the gabion products themselves, look for compliance with specific material and performance standards, such as ASTM A975 for double-twisted hexagonal woven mesh gabions in North America, and EN 10223-3 for European markets. These standards define the minimum requirements for wire tensile strength, zinc coating mass, mesh opening dimensions, and overall product integrity. Additionally, a supplier's adherence to environmental management standards like ISO 14001 can indicate a commitment to sustainable practices. Transparency in providing test reports from independent third-party laboratories, confirming adherence to these standards, further enhances a supplier's trustworthiness and ensures that the gabion baskets you procure meet the highest benchmarks for durability and performance in your project.

-

Q: What is the typical delivery schedule for bulk orders of narrow gabion baskets?

A: The typical delivery schedule for bulk orders of narrow gabion baskets from a reliable narrow gabion baskets supplier generally depends on several factors: the order quantity, the specific customization requirements, current production capacity, and the shipping destination. For standard sizes and materials, lead times can range from 2 to 4 weeks for manufacturing and preparation, followed by transit time which varies based on geographical location and chosen shipping method (sea freight, air freight, or land transport). For highly customized or exceptionally large orders, lead times may extend to 6-8 weeks or more. Leading suppliers, committed to client satisfaction, will provide a detailed production and delivery schedule at the time of order confirmation, often including options for expedited shipping if project timelines are exceptionally tight. It is always advisable to communicate your project's critical deadlines during the quotation phase to allow the narrow gabion baskets supplier to provide the most accurate and efficient delivery plan. Effective communication and logistical planning between the client and supplier are key to ensuring timely procurement and seamless project execution.

-

Q: Are gabion structures environmentally friendly?

A: Yes, gabion structures are widely recognized for their significant environmental benefits and are considered a highly sustainable solution in civil and environmental engineering. Their inherent permeability allows for natural drainage, reducing hydrostatic pressure behind structures and preventing soil erosion, which helps maintain natural hydrological cycles. Furthermore, gabions can be filled with locally available infill materials such as rocks, crushed concrete, or recycled aggregates, which dramatically reduces transportation costs and the carbon footprint associated with material sourcing. This also minimizes the reliance on virgin materials. The ability of gabions to integrate with the natural landscape and support vegetation growth over time creates a "green" structure that enhances biodiversity, provides habitat for local flora and fauna, and improves aesthetic appeal. Unlike rigid concrete structures, gabions have a lower embodied energy in their production and assembly. The long service life of Heavy Zinc Coated Galvanized Gabion Baskets also contributes to sustainability by reducing the frequency of replacement and associated resource consumption. These ecological advantages, coupled with their structural efficacy, make gabions an increasingly preferred choice for engineers and environmentalists alike, aligning with global efforts towards sustainable infrastructure development and ecological restoration.

Conclusion: The Imperative of Partnering with a Premier Supplier

The increasing complexity of modern infrastructure and environmental management projects underscores the critical importance of selecting a highly competent narrow gabion baskets supplier. As detailed throughout this exposition, the decision extends far beyond mere product acquisition, encompassing a comprehensive evaluation of manufacturing expertise, adherence to stringent international quality standards, a proven track record of successful project experience, and an unwavering commitment to client support and trustworthiness. The versatility of Heavy Zinc Coated Galvanized Gabion Basket Rock Walls, coupled with their inherent durability, environmental benefits, and adaptability to diverse site conditions, positions them as indispensable tools for engineers and developers alike. From critical erosion control in riverine environments to the creation of robust, aesthetically pleasing retaining walls in urban landscapes, the specific characteristics of narrow gabions provide unique advantages where space or design precision is paramount. The meticulous manufacturing processes, including advanced galvanization techniques and precision weaving or welding, ensure that these products deliver on their promise of long service life and exceptional structural integrity. Furthermore, the ability of a leading narrow gabion baskets supplier to offer tailored solutions, combined with comprehensive technical and logistical support, transforms a simple transaction into a strategic partnership, mitigating risks and optimizing project outcomes.

In an era defined by evolving environmental challenges and heightened demands for sustainable, resilient infrastructure, the role of a premier narrow gabion baskets factory or supplier becomes more critical than ever. Their capacity to innovate, to consistently meet and exceed international benchmarks, and to provide comprehensive support across the project lifecycle directly contributes to the longevity, safety, and cost-efficiency of constructed assets. As discussions in leading geotechnical engineering forums often highlight, the success of gabion-based solutions is intrinsically linked to the quality of materials and the reliability of the supply chain. Academic papers on geohazard mitigation consistently emphasize that while design principles are paramount, the actual performance in the field is ultimately determined by the physical and mechanical properties of the gabion units themselves, and these properties are a direct reflection of the supplier's manufacturing prowess and quality control protocols. Therefore, for any entity embarking on a project requiring resilient and adaptable earth retention or erosion control systems, investing in a partnership with an authoritative and trusted narrow gabion baskets supplier is not merely a preference but a fundamental requirement for achieving enduring success and ensuring the long-term integrity of vital infrastructure.

-

Visualizing Gabion 3D Integration in Urban Landscapes with Rendering

NewsJul.23,2025

-

The Design and Sustainability of Gabion Wire Mesh Panels

NewsJul.23,2025

-

The Acoustic Performance of Gabion Sound Barriers in Urban Environments

NewsJul.23,2025

-

Mastering the Installation of Galvanized Gabion Structures

NewsJul.23,2025

-

Gabion Boxes: Pioneering Sustainable Infrastructure Across the Globe

NewsJul.23,2025

-

Custom PVC Coated Gabion Boxes for Aesthetic Excellence

NewsJul.23,2025

-

Installation Tips for Gabion Wire Baskets in Erosion Control Projects

NewsJul.21,2025