ਫਰ. . 15, 2025 13:16 Back to list

narrow gabion baskets factories

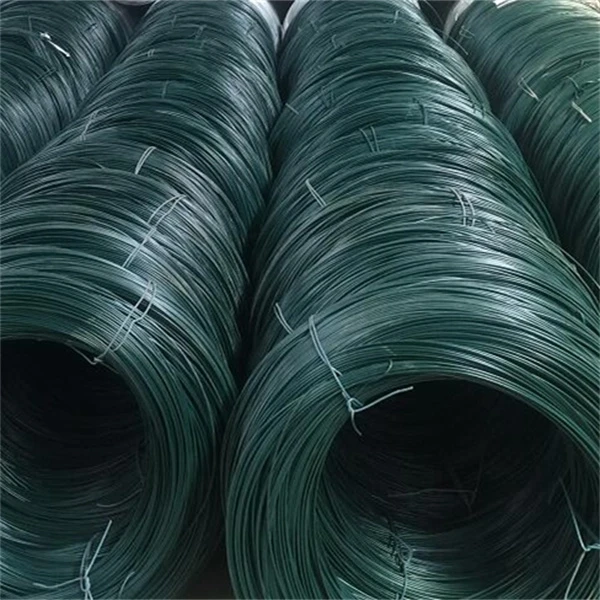

PVC gabions have increasingly become a preferred choice for civil engineering and landscaping projects. Offering a robust and flexible solution for erosion control, retaining walls, and various aquatic applications, PVC gabions distinguish themselves with their versatility and durability. Their manufacturing involves coating steel wire mesh with polyvinyl chloride, a feature that delivers enhanced resistance against environmental factors.

From an authoritative perspective, PVC gabions have been embraced by regulatory agencies and construction standards worldwide as a sustainable engineering solution. Their environmental impact is minimal, as they blend seamlessly with the landscape and allow for natural vegetation growth through their structure. This not only promotes biodiversity but also enhances the aesthetic appeal of the project site. Engineers and planners frequently reference research and case studies that detail the successful implementation of PVC gabions in diverse projects, thereby affirming their efficacy and reliability. Trust in PVC gabions comes from decades of proven performance and satisfied users. Testimonials from municipalities, civil engineers, and contractors underline the product's reliability in delivering strong and lasting support for infrastructure projects. Additionally, the use of PVC-coated gabions is supported by warranties offered by manufacturers, assuring project stakeholders of their investment's longevity. In summary, PVC gabions provide an innovative, durable, and eco-friendly solution for numerous construction challenges. Their ability to resist corrosion, flexibility in design applications, and contribution to environmental sustainability make them an excellent choice for modern engineering projects. A focus on proper installation and selection of infill materials can further optimize their function. As a product that embodies the principles of Experience, Expertise, Authoritativeness, and Trustworthiness, PVC gabions stand out as a remarkable option for today's demanding infrastructure needs.

From an authoritative perspective, PVC gabions have been embraced by regulatory agencies and construction standards worldwide as a sustainable engineering solution. Their environmental impact is minimal, as they blend seamlessly with the landscape and allow for natural vegetation growth through their structure. This not only promotes biodiversity but also enhances the aesthetic appeal of the project site. Engineers and planners frequently reference research and case studies that detail the successful implementation of PVC gabions in diverse projects, thereby affirming their efficacy and reliability. Trust in PVC gabions comes from decades of proven performance and satisfied users. Testimonials from municipalities, civil engineers, and contractors underline the product's reliability in delivering strong and lasting support for infrastructure projects. Additionally, the use of PVC-coated gabions is supported by warranties offered by manufacturers, assuring project stakeholders of their investment's longevity. In summary, PVC gabions provide an innovative, durable, and eco-friendly solution for numerous construction challenges. Their ability to resist corrosion, flexibility in design applications, and contribution to environmental sustainability make them an excellent choice for modern engineering projects. A focus on proper installation and selection of infill materials can further optimize their function. As a product that embodies the principles of Experience, Expertise, Authoritativeness, and Trustworthiness, PVC gabions stand out as a remarkable option for today's demanding infrastructure needs.

Latest news

-

Why PVC Coated Gabion Mattress Is the Best Solution for Long-Term Erosion Control

NewsMay.23,2025

-

Gabion Wire Mesh: The Reinforced Solution for Modern Construction and Landscape Design

NewsMay.23,2025

-

Gabion Wall: The Flexible, Seismic-Resistant Solution for Modern Landscaping and Construction

NewsMay.23,2025

-

Gabion Wall Solutions: The Durable, Decorative, and Affordable Choice for Every Landscape

NewsMay.23,2025

-

Gabion Basket: The Durable and Flexible Alternative to Traditional Retaining Walls

NewsMay.23,2025

-

Gabion Basket: The Proven Solution for Slope Stability and Flood Control

NewsMay.23,2025

-

Versatility of Chain Link Fence Gabion

NewsMay.13,2025

Manufacturer of Silk Screen Products

QuanhuaProvide high-quality products and services to global customers.