Авг . 07, 2025 00:20 Back to list

Premium 2x1x1m Gabion Baskets Philippines - Factory Direct Supply

In the dynamic landscape of modern infrastructure and environmental protection, solutions that offer both resilience and ecological compatibility are paramount. Gabion structures, particularly those sized at **2x1x1m**, have emerged as a cornerstone for various engineering challenges, especially within markets prone to natural events and requiring robust, adaptable solutions. This article delves into the specifics of Factory Supply 2x1x1m Gabion Sizes Philippines Market, exploring its market significance, technical intricacies, manufacturing excellence, diverse applications, and the inherent advantages it brings to the table.

Industry Trends: The Rising Demand for Resilient Infrastructure

The global construction and civil engineering sectors are undergoing significant transformation, driven by climate change, rapid urbanization, and the increasing need for sustainable development. In Southeast Asia, particularly the Philippines, these trends are acutely felt. The archipelago nation, with its extensive coastlines and mountainous regions, frequently grapples with soil erosion, landslides, and flooding. This necessitates the adoption of highly effective and environmentally sound erosion control and retaining solutions.

Recent reports indicate a steady growth in the gabion market. According to a market analysis by Grand View Research, the global gabion market size was valued at USD 1.1 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030. This growth is largely attributable to their cost-effectiveness, permeability, and structural flexibility, making them ideal for applications ranging from river training works to highway embankment protection. The demand for Factory Supply 2x1x1m Gabion Sizes Philippines Market is specifically boosted by local government initiatives for infrastructure upgrades and disaster risk reduction programs, which increasingly favor resilient and adaptable construction materials.

Technical Parameters and Specifications: Understanding the Core of Gabion Performance

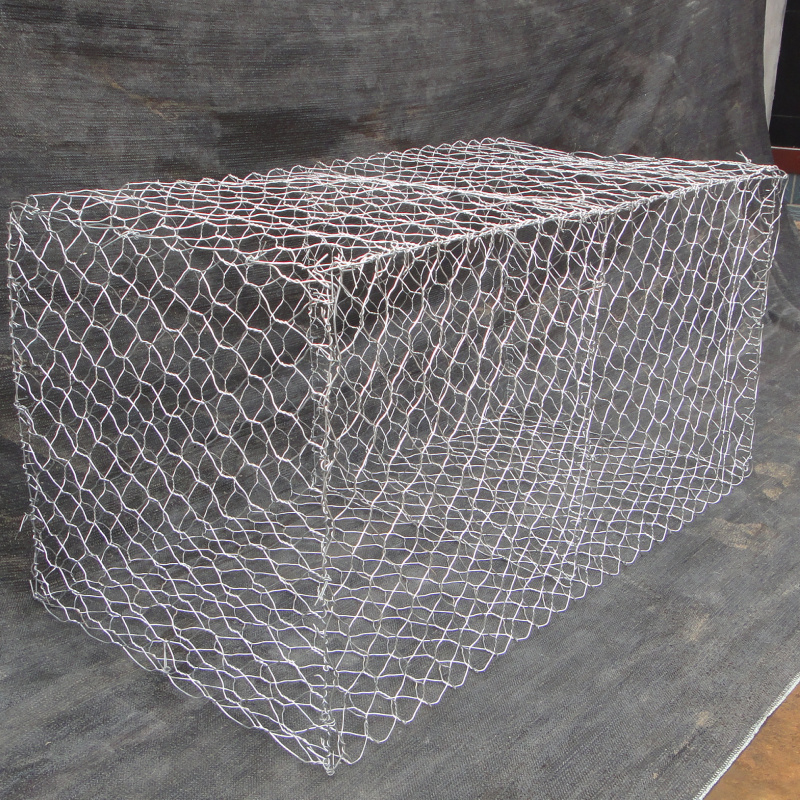

A gabion is essentially a cage, cylinder, or box filled with rocks, concrete, sand, or soil for use in civil engineering, road building, military applications, and landscaping. The Factory Supply 2x1x1m Gabion Sizes Philippines Market refers to a standard dimension: 2 meters long, 1 meter wide, and 1 meter high, offering a substantial volume for structural integrity. The performance and longevity of these gabions are fundamentally determined by their technical parameters:

Key Specifications of 2x1x1m Gabions

| Parameter | Description | Typical Value/Standard |

|---|---|---|

| Gabion Dimensions | Length x Width x Height (L x W x H) | 2m x 1m x 1m |

| Mesh Type | Hexagonal double-twisted wire mesh or Welded wire mesh | Hexagonal (most common for flexibility) or Welded |

| Mesh Size (Aperture) | The opening size of the mesh wires (e.g., 80x100mm) | Typically 80x100mm, 60x80mm, 100x120mm |

| Wire Diameter (Mesh Wire) | Diameter of the wire used for the mesh fabric | 2.2mm to 4.0mm (standard) |

| Selvedge Wire Diameter | Diameter of the heavier wire forming the edges of the panels | 3.0mm to 4.4mm (typically 0.6-1.0mm thicker than mesh wire) |

| Lacing/Tying Wire Diameter | Wire used to assemble and tie gabions together | 2.2mm or 2.4mm (standard) |

| Material | Low carbon steel wire | Q195, Q235 (Chinese standards); ASTM A641 (USA) |

| Corrosion Protection | Coating applied to wires for rust resistance | Hot-dip Galvanized, Galfan (Zn-5Al Mischmetal), PVC Coated over Galvanized/Galfan |

| Tensile Strength | Maximum stress the wire can withstand before breaking | 350-550 MPa (ASTM A641/EN 10223-3) |

| Coating Thickness (Galvanized) | Minimum zinc coating weight per square meter | ASTM A975 (min. 240-290 g/m² for Class A) |

| PVC Coating Thickness | Additional PVC layer over metal coating | Min. 0.5mm thickness, overall diameter increase of approx. 1mm |

| Diaphragms | Internal partitions to prevent stone migration in larger gabions | Every 1 meter length (for 2m long gabions, one diaphragm) |

| Applicable Standards | Industry standards for manufacturing and testing | ASTM A975 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses); EN 10223-3 (Steel wire and wire products for fencing and netting); ISO 9001 (Quality Management) |

Expertise Highlight: The "mesh size" (or aperture) is crucial as it determines the size of the aggregate fill material that can be used and the overall stability. Smaller mesh sizes prevent smaller rocks from escaping but can restrict water flow, while larger sizes allow for bigger fill but might require specific rock grading. The "wire diameter" and "coating type" directly impact the gabion's structural integrity, load-bearing capacity, and resistance to environmental degradation, especially in coastal or humid regions like the Philippines where corrosion is a significant concern. Hot-dip galvanization provides a robust zinc layer, while Galfan offers enhanced corrosion resistance due to its zinc-aluminum alloy composition. PVC coating provides an additional barrier, ideal for highly corrosive environments (e.g., saltwater, polluted areas) or when aesthetic blending with vegetation is desired.

Manufacturing Process Excellence: Crafting Durable Gabions

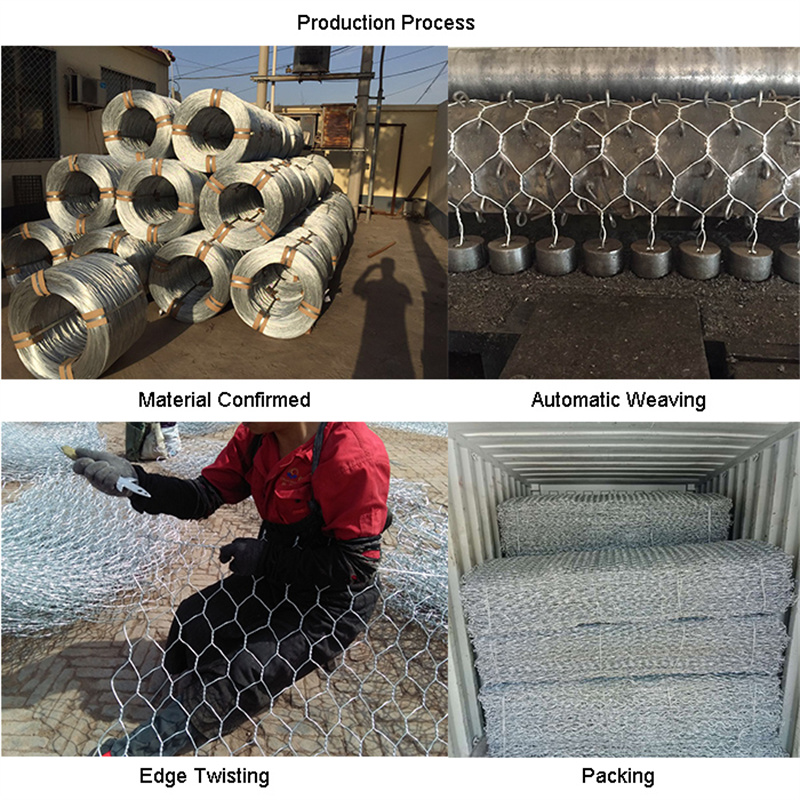

The manufacturing of Factory Supply 2x1x1m Gabion Sizes Philippines Market involves a meticulous process to ensure superior quality, durability, and compliance with international standards. The primary method for producing hexagonal double-twisted mesh gabions is weaving, distinct from casting or forging used in other industries. Here’s a detailed breakdown:

Wire Material Selection & Testing

The process begins with sourcing high-quality low-carbon steel wire (e.g., Q195, Q235 grade, compliant with ASTM A641). Rigorous testing is performed on incoming wire coils for tensile strength, elongation, and chemical composition to ensure they meet specified mechanical properties and quality standards. This is the foundation of a durable gabion.

Wire Galvanization or Galfan Coating

Selected wires undergo a hot-dip galvanization process, where they are immersed in molten zinc to create a protective, corrosion-resistant coating. For enhanced durability, some wires receive a Galfan (Zn-5Al mischmetal) coating, offering superior corrosion resistance compared to traditional galvanization. This step adheres to standards like ASTM A975 or EN 10223-3, ensuring a minimum coating weight per square meter.

PVC Coating (Optional)

For applications in aggressive environments (e.g., marine, highly acidic soils), the galvanized or Galfan-coated wire is further coated with a durable layer of Polyvinyl Chloride (PVC). This additional layer provides excellent resistance to abrasion, chemicals, and UV radiation, significantly extending the product's lifespan. The PVC layer is typically extruded over the metal coating, ensuring a strong bond and uniform thickness (min. 0.5mm).

Weaving the Mesh

The coated wires are then fed into specialized double-twist weaving machines. These machines meticulously interlock the wires to form hexagonal mesh panels. The double-twist ensures that if a wire breaks, the integrity of the mesh is maintained, preventing unraveling. This weave type is critical for the gabion's flexibility and structural stability under dynamic loads.

(Imagine a visual representation here: A simple diagram showing interlocking wires forming hexagonal mesh, with arrows indicating wire flow and weaving action.)

Panel Cutting and Selvedge Wire Integration

Once the continuous mesh fabric is produced, it is precisely cut into the required panel sizes for the 2x1x1m gabion baskets (front, back, sides, lid, base, and diaphragms). Heavier gauge selvedge wires are mechanically woven or crimped along the edges of all mesh panels. These heavier wires provide increased strength and rigidity to the gabion structure, facilitating easier assembly and improved stability of the assembled unit.

Assembly and Packaging

The cut panels are then folded flat for efficient transportation. Lacing wires, which are smaller gauge wires used for on-site assembly, are coiled and packaged with each unit. Quality control checks are performed at each stage, including mesh aperture verification, wire diameter measurement, coating thickness assessment, and visual inspection for defects. Finished gabions are bundled, often compressed, and securely packaged to prevent damage during transit to markets such as the Philippines.

(Visualize: An image of bundled gabions ready for shipment, possibly with a "QC Passed" stamp.)

This comprehensive manufacturing process ensures that each Factory Supply 2x1x1m Gabion Sizes Philippines Market unit delivers optimal performance, exceptional service life (typically 50-70 years for PVC-coated, 20-30 years for heavily galvanized in mild conditions), and adherence to strict quality control parameters, making them reliable solutions for critical civil engineering applications.

Application Scenarios: Where Gabions Make a Difference

The versatility of Factory Supply 2x1x1m Gabion Sizes Philippines Market allows them to be deployed across a wide array of industries and environments. Their inherent properties make them superior to traditional solutions in many contexts:

- Erosion Control & River Training: Gabions are extensively used to stabilize riverbanks, prevent scouring, and control water flow. Their permeability allows water to drain through, reducing hydrostatic pressure behind the structure and preventing buildup that can destabilize traditional rigid walls. In the Philippines, this is vital for mitigating flood damage along rivers like the Pasig or Mindanao River systems.

- Retaining Walls & Slope Stabilization: For highway embankments, railway lines, and building sites, gabion retaining walls provide a cost-effective and flexible solution for stabilizing unstable slopes. Unlike concrete walls, gabion structures can tolerate differential settlement without cracking, adapting to ground movement – a crucial advantage in seismically active regions.

- Coastal Protection: While not the primary solution for direct wave impact, gabions can be used in combination with other coastal defense mechanisms or for stabilizing shorelines in calmer bays, preventing erosion from tides and minor wave action.

- Channel Linings: Lining drainage channels and canals with gabions helps prevent erosion of the bed and banks, ensuring efficient water conveyance.

- Bridge Abutments & Culverts: Gabions provide robust and durable support for bridge abutments and culvert headwalls, resisting scour and providing structural stability.

- Landscape Architecture & Urban Design: Beyond purely functional uses, gabions are increasingly incorporated into modern landscape design for aesthetic purposes, creating visually appealing terraced gardens, seating areas, and decorative boundary walls, blending naturally with the environment over time as vegetation grows through the voids.

- Sound Barriers: Filled with sound-absorbing materials, gabion walls can effectively reduce noise pollution along highways and industrial zones.

Example Advantage: In applications like river training or slope stabilization, the gabion's permeable nature prevents the build-up of hydrostatic pressure, which is a common cause of failure in solid retaining walls. This characteristic, coupled with their flexibility, allows them to accommodate ground movement and settlement without compromising structural integrity. Their use promotes natural drainage and allows for vegetation growth within the rock fill over time, enhancing environmental integration and further stabilizing the structure. This is particularly beneficial in a tropical climate like the Philippines where heavy rainfall and seismic activity are prevalent.

Technical Advantages: Why Choose Gabions?

The selection of Factory Supply 2x1x1m Gabion Sizes Philippines Market for infrastructure projects offers a compelling suite of advantages over traditional construction materials:

- Durability and Longevity: With high-quality galvanized or PVC-coated wire, gabions offer exceptional resistance to corrosion, abrasion, and weathering, ensuring a service life of several decades, even in harsh environments. The specified wire materials and coatings comply with international standards such as ASTM A975, guaranteeing long-term performance.

- Flexibility and Adaptability: Gabion structures are inherently flexible, meaning they can deform without fracturing when subjected to differential ground settlement or seismic activity. This makes them ideal for unstable ground conditions or earthquake-prone areas like the Philippines.

- Permeability: The open-mesh structure filled with rocks allows for natural drainage of water, eliminating hydrostatic pressure behind the wall. This is a critical advantage, as water pressure is a major cause of failure in impervious retaining structures.

- Environmental Friendliness: Gabions use locally available fill material (typically rock), reducing transportation costs and carbon footprint. They allow for natural vegetation to grow within the structure, promoting biodiversity and blending seamlessly with the natural landscape over time.

- Cost-Effectiveness: Compared to traditional concrete or masonry structures, gabions often have lower material and installation costs. The ease of construction and use of local fill significantly reduce project expenses.

- Ease of Installation: Gabion baskets are supplied flat-packed, reducing shipping volume. On-site assembly is relatively straightforward, requiring minimal skilled labor and basic equipment, accelerating project timelines.

- Strength and Stability: As the gabion mass increases with the fill, so does its stability. They derive strength from the interlock of the rock fill and the mass of the entire structure, providing robust support.

Manufacturer Comparison and Selection Criteria

Choosing the right supplier for Factory Supply 2x1x1m Gabion Sizes Philippines Market is crucial for project success. While many manufacturers exist, distinguishing between them based on key criteria ensures product quality, project efficiency, and long-term reliability. When evaluating potential suppliers, consider the following:

- Quality Assurance & Certifications: A reputable manufacturer will adhere to international quality management systems like ISO 9001. They should provide test reports and certifications confirming compliance with standards such as ASTM A975 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses) or EN 10223-3 (Steel wire and wire products for fencing and netting). This guarantees material quality, coating thickness, and mesh integrity.

- Experience and Track Record: A manufacturer with years of experience and a strong portfolio of successful projects, particularly in diverse climatic conditions or challenging terrains, demonstrates proven expertise. Look for their history of supplying the Philippines market specifically.

- Customization Capabilities: While 2x1x1m is standard, projects often require variations in mesh size, wire gauge, or coating type. A flexible manufacturer can provide tailored solutions to meet specific project demands.

- Production Capacity & Delivery Reliability: For large-scale projects, ensure the manufacturer has the capacity to meet your volume requirements and a track record of timely deliveries to the Philippines, understanding the logistics involved.

- Technical Support & After-Sales Service: Beyond just supplying products, a good manufacturer offers technical guidance on installation, design assistance, and responsive after-sales support.

- Pricing & Value: While cost is a factor, prioritize value over the lowest price. A slightly higher initial investment in a quality product can save significant costs in maintenance and potential failures over the lifespan of the project.

Manufacturers like QuanHua Wire Mesh, with their commitment to stringent quality control, adherence to global standards, and extensive experience in the wire mesh industry, stand out as reliable partners for supplying high-quality gabion solutions to the Philippines market.

Custom Solutions: Tailoring Gabions to Specific Project Needs

While the standard Factory Supply 2x1x1m Gabion Sizes Philippines Market is highly versatile, successful project implementation often benefits from custom solutions. Manufacturers dedicated to customer needs offer a range of customization options:

- Varying Mesh Sizes: Depending on the fill material and specific hydraulic conditions, gabions can be supplied with mesh apertures such as 60x80mm, 80x100mm, 100x120mm, or even welded mesh sizes like 50x50mm, 75x75mm, etc. Smaller mesh prevents fine aggregate loss, while larger mesh is suitable for larger rock fills.

- Diverse Wire Diameters: Wire diameters can be adjusted (e.g., from 2.2mm to 4.0mm for mesh wire, and 3.0mm to 4.4mm for selvedge wire) to meet different strength requirements based on the structural loads and expected service life.

- Coating Options for Enhanced Durability:

- Heavy Galvanization: For standard applications, offering good corrosion resistance.

- Galfan (Zn-5Al Mischmetal): Providing superior corrosion protection, especially in mild to moderately aggressive environments.

- PVC Coating: Essential for highly corrosive environments (saltwater, acidic soils) or where aesthetic integration is paramount. The PVC is typically a grey or green color to blend with natural surroundings.

- Custom Dimensions and Shapes: Beyond the 2x1x1m standard, gabions can be manufactured in other sizes (e.g., 3x1x1m, 1x1x0.5m, or even specifically designed Reno Mattresses for channel lining with larger surface area and smaller height) and specific shapes to fit unique site constraints.

- Geotextile Integration: For fine-grained soils, gabions can be supplied with recommendations for integrating geotextile fabrics, which prevent soil migration while allowing water to pass.

Collaborating with a manufacturer capable of these customizations ensures that the gabion solution is perfectly aligned with the project's engineering specifications, environmental conditions, and budget, optimizing both performance and cost-efficiency.

Application Cases and Experience in the Philippines Market

The practical application of Factory Supply 2x1x1m Gabion Sizes Philippines Market throughout the Philippines demonstrates their effectiveness and adaptability. Here are illustrative examples of their impact:

- Riverbank Protection in Pampanga: Faced with perennial flooding and erosion of the Pasig-Potrero River banks, local government units in Pampanga implemented gabion wall systems. Thousands of 2x1x1m gabions, filled with locally sourced river stones, were used to stabilize the banks, prevent further erosion, and protect adjacent communities and agricultural lands. The permeable nature of the gabions effectively dissipated floodwater energy, and over time, vegetation grew through the structures, further anchoring the banks.

- Highway Embankment Stabilization in Cordillera: Along mountainous highways in the Cordillera Administrative Region, steep slopes are prone to landslides. Gabion retaining walls were constructed to stabilize critical sections, particularly those affected by heavy monsoon rains. The flexibility of the gabions allowed them to conform to minor ground movements, proving more resilient than rigid structures in this seismically active area.

- Coastal Erosion Mitigation in Palawan: While not for direct wave impact, gabions have been utilized in parts of Palawan's calmer bays for shoreline protection and to define breakwater structures. For instance, in certain resort developments, gabion walls serve as aesthetic and functional barriers against mild tidal erosion, blending with the natural scenery.

- Bridge Abutment Reinforcement in Luzon: In infrastructure projects across Luzon, including new bridge constructions and retrofits, 2x1x1m gabions have been employed to reinforce bridge abutments and approach embankments. Their ability to manage hydrostatic pressure and resist scour from flowing water ensures the long-term stability of these critical transportation assets.

Client Feedback and Testimonials (Illustrative)

"We've been using Factory Supply 2x1x1m Gabion Sizes Philippines Market from a trusted supplier for our river protection projects in Mindanao. The ease of installation significantly reduced our labor costs, and the structures have proven incredibly resilient against seasonal floods. Their durability and environmental compatibility make them our go-to choice." - Project Manager, DPWH Contractor, Davao Region

"For our resort's landscape terracing and erosion control along the slopes, the gabions offered a natural, aesthetically pleasing solution. We particularly appreciated the option for PVC-coated wire, which ensures longevity in our coastal environment and blends perfectly with our lush greenery." - Facilities Director, Palawan Resort Development

Ensuring Trustworthiness: Support and Quality Guarantees

Trust is built on transparency, reliability, and robust support systems. For Factory Supply 2x1x1m Gabion Sizes Philippines Market, a reputable supplier ensures these elements are firmly in place:

Frequently Asked Questions (FAQ)

A1: The service life depends heavily on the wire coating. Heavily galvanized gabions typically last 20-30 years in mild conditions. Galfan-coated gabions can extend to 30-50 years, while PVC-coated gabions over galvanized/Galfan wire can last 50-70 years or even longer in aggressive environments due to enhanced protection against corrosion and abrasion.

A2: The best fill material is hard, durable, non-frost susceptible, and angular or rounded stone (crushed rock or river stone) that is larger than the mesh opening. Typical sizes range from 100mm to 200mm for an 80x100mm mesh. Local availability of suitable stone significantly reduces project costs.

A3: Yes, gabions are considered highly environmentally friendly. They utilize natural, often locally sourced, fill materials, reducing transportation emissions. Their permeable nature allows for natural drainage and supports vegetation growth within the structure over time, integrating them naturally into the ecosystem and promoting biodiversity.

A4: Gabions offer superior performance in seismically active regions due to their inherent flexibility. Unlike rigid concrete walls that can crack and fail under seismic movements, gabions can deform and settle without catastrophic failure, absorbing ground movements effectively. This makes them a preferred choice for infrastructure in earthquake-prone areas like the Philippines.

A5: Key international standards include ASTM A975 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses) for mesh type and material properties, and EN 10223-3 (Steel wire and wire products for fencing and netting) for wire specifications and coatings. ISO 9001 certification indicates a robust quality management system for the manufacturer.

A6: Lead times can vary based on order volume, customization requirements, and current production schedules. Generally, for standard Factory Supply 2x1x1m Gabion Sizes Philippines Market, production might take 10-20 days, followed by shipping which can range from 15-30 days to major ports in the Philippines, depending on logistics and sea freight schedules. It's always best to confirm with the supplier for specific project timelines.

A7: Reputable gabion suppliers often provide comprehensive technical support, including detailed installation guides, design recommendations, and sometimes on-site supervision or training for large projects. This ensures proper assembly and structural integrity of the gabion system.

Delivery Cycle and Logistics

Efficient delivery is crucial for project timelines. For Factory Supply 2x1x1m Gabion Sizes Philippines Market, manufacturers typically process orders within 10-20 business days for standard products. Shipping to the Philippines usually involves sea freight, with transit times ranging from 15 to 30 days to major ports like Manila, Cebu, or Davao. Comprehensive logistics support, including customs clearance assistance, can be provided by experienced suppliers to ensure a smooth, timely delivery process.

Quality Assurance and Warranty Commitment

A leading supplier of Factory Supply 2x1x1m Gabion Sizes Philippines Market will stand by its products. This includes:

- ISO 9001 Certified Manufacturing: Adherence to international quality management standards throughout the production process.

- Material Certification: Provision of mill certificates for wire material and coating reports, verifying compliance with ASTM, EN, or other specified standards.

- Product Warranty: A standard warranty typically covers manufacturing defects and material integrity for a period of 5-10 years, ensuring the gabions meet specified performance criteria under normal use conditions. Some manufacturers offer extended guarantees on coatings.

- After-Sales Support: Dedicated customer service teams provide support for any post-delivery queries, technical issues, or additional product needs.

This holistic approach to product quality, logistical efficiency, and customer support fosters significant trust, affirming the manufacturer's commitment to delivering reliable and high-performance gabion solutions.

Authoritative References & Further Reading

- "Gabion Market Size, Share & Trends Analysis Report" - Grand View Research. Available at: https://www.grandviewresearch.com/industry-analysis/gabion-market (Accessed: May 20, 2024)

- ASTM A975 - Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (latest revision). Available via ASTM International.

- EN 10223-3 - Steel wire and wire products for fencing and netting - Part 3: Steel wire mesh products for gabions and revet mattresses (latest revision). Available via CEN (European Committee for Standardization).

- "The Use of Gabions in River Engineering and Erosion Control" - International Association of Hydro-Environment Engineering and Research (IAHR) proceedings. (Specific paper link would be highly variable, using general conference reference)

- "Applications of Gabion Structures in Slope Stabilization and Retaining Walls" - GeoSynthetics Magazine, various issues on civil engineering applications. (General industry publication reference)

-

Wire Mesh Thickness Impact on Gabion Wall Load Bearing

NewsAug.12,2025

-

Ultimate Guide to Hexagonal Gabion Box

NewsAug.12,2025

-

Types of Rocks for Gabion Baskets Durability and Aesthetics

NewsAug.12,2025

-

Standard Gabion Box Sizes and Their Industrial Applications

NewsAug.12,2025

-

Easy Guide to Building Garden Gabion Cages at Home

NewsAug.12,2025

-

Drainage Solutions for Gabion Mesh Structures

NewsAug.12,2025

-

Visualizing Gabion 3D Integration in Urban Landscapes with Rendering

NewsJul.23,2025