Nov . 04, 2024 20:25 Back to list

gabion wall footing manufacturer

Understanding Gabion Wall Footings A Comprehensive Guide

Gabion walls are a popular choice for various applications, including erosion control, landscape design, and construction projects. As versatile and effective solutions, these walls consist of wire mesh containers filled with rocks, concrete, or other materials. However, the stability and longevity of a gabion wall depend significantly on its footing. Therefore, understanding the role of gabion wall footings and selecting the right manufacturer is crucial.

What is a Gabion Wall Footing?

A gabion wall footing is the base or foundation upon which a gabion wall is built. It is designed to support the weight of the wall and provide stability against lateral pressures from soil, water, and other environmental factors. Properly designed footings prevent movement and settling, ensuring that the wall maintains its integrity over time. The footing's depth and width can vary based on the wall's height, the type of soil, and local environmental conditions.

Importance of Quality Manufacturing

When considering a gabion wall, the quality of materials and construction is paramount. A reputable gabion wall footing manufacturer will provide products that meet industry standards regarding strength, durability, and resistance to corrosion. Low-quality materials can lead to premature failure of the footing, resulting in wall collapse or shifting, which can be costly to repair.

Choosing a manufacturer experienced in the specific requirements for gabion wall footings ensures that you receive products that are tailored to your project's needs

. An established manufacturer will typically offer a range of footing options, including pre-fabricated sizes and custom designs, allowing for a more versatile application across different projects.Key Factors in Choosing a Manufacturer

gabion wall footing manufacturer

1. Experience and Expertise Look for manufacturers with a proven track record in producing gabion wall footings. Their experience will often translate into better quality assurance and innovation in design.

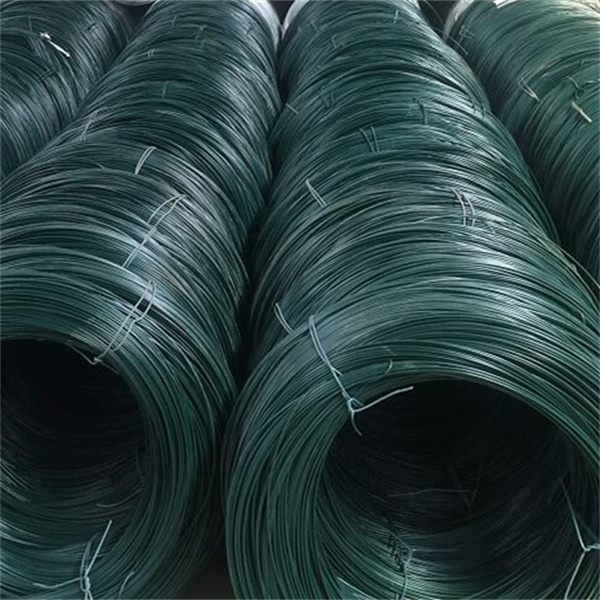

2. Material Quality The materials used in the footings should be high-grade, ensuring they can withstand environmental stresses. Steel wire mesh should be galvanized or coated for corrosion resistance, while the fill material must be durable and suitable for the intended application.

3. Customization Not all projects are the same. A good manufacturer should offer customization options to meet specific project requirements, whether that's size, shape, or additional features.

4. Compliance and Certifications Ensure that the manufacturer adheres to industry regulations and possesses necessary certifications. This ensures that the products they provide will perform as expected under various conditions.

5. Customer Support Quality customer support and technical assistance are vital. A reliable manufacturer should be willing to answer questions and provide guidance during the design and installation process.

Conclusion

Gabion wall footings are critical to the success of gabion walls, influencing their stability and longevity. By choosing the right manufacturer, you ensure that your project benefits from high-quality materials and expertise tailored to your specific needs. Investing time in selecting a reputable provider will ultimately result in a more durable and effective gabion wall, protecting your landscape and infrastructure for years to come. Whether for residential, commercial, or environmental projects, understanding the importance of gabion wall footings and partnering with the right manufacturer is the first step toward achieving a robust construction solution.

-

The Role of Galvanized Gabion Mesh in Riverbank Protection

NewsJun.26,2025

-

The Role of Gabion Basket Raised Bed in Sustainable Gardening

NewsJun.26,2025

-

Quality Assurance of Wire Mesh Gabion Baskets

NewsJun.26,2025

-

Installation Guide for Welded Gabion Box

NewsJun.26,2025

-

How to Choose the Right Gabion Box

NewsJun.26,2025

-

Different Types of Gabion Wire Mesh

NewsJun.26,2025

-

Why PVC Coated Gabion Mattress Is the Best Solution for Long-Term Erosion Control

NewsMay.23,2025