Sep . 16, 2024 07:39 Back to list

wholesale gabion wire gauge

Understanding Wholesale Gabion Wire Gauge for Effective Construction

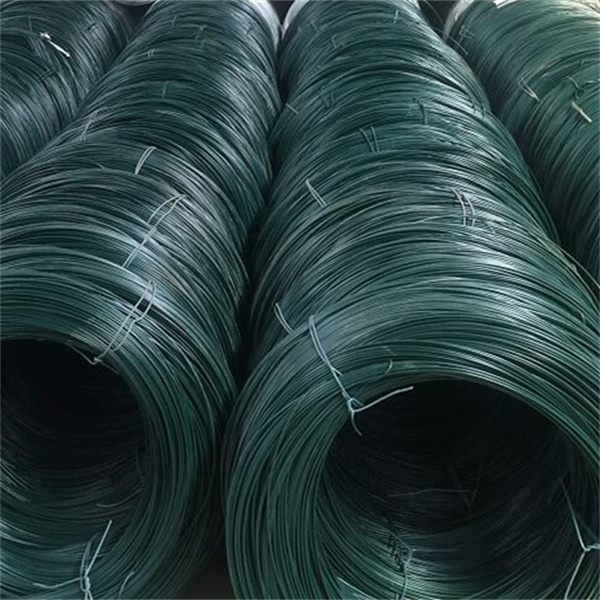

In the realm of construction and landscaping, gabions have become an increasingly popular solution for various applications, from erosion control to decorative elements. These wire mesh cages filled with rocks or other materials provide structural support and aesthetics, making them a practical choice for engineers and designers alike. One critical factor to consider when purchasing wholesale gabions is the wire gauge, which directly affects the durability and effectiveness of these structures.

What is Wire Gauge?

Wire gauge refers to the diameter of the wire used in the construction of gabions. In wire construction, the smaller the gauge number, the thicker the wire; conversely, larger numbers indicate thinner wires. Common wire gauges for gabions typically range from 8 to 12. For most applications, a wire gauge of 8 or 9 is preferable, as it balances strength and flexibility, allowing the gabions to withstand varying weather conditions and shifting soil.

Importance of Wire Gauge in Gabion Quality

The wire gauge plays a pivotal role in determining the quality and longevity of gabions. Thicker wires (lower gauge numbers) are more resistant to bending, breaking, and rusting over time, making them ideal for installations in harsh environments. In contrast, thinner wires may suffice for decorative purposes or less demanding applications but might not offer the needed stability for structural use.

Moreover, when selecting wholesale gabions, it is crucial to consider the wire’s coating. Galvanization (the process of applying a protective zinc coating to steel) can significantly enhance the corrosion resistance of gabions. For environments exposed to moisture or saline conditions, coated gabion wires are essential as they extend the life of the structure significantly.

wholesale gabion wire gauge

Applications of Wholesale Gabion Wire

Wholesale gabion wire is versatile and can be utilized for various purposes. Civil engineering projects often employ gabions for retaining walls, riverbank stabilization, and slope protection. By using thicker gauge wire, engineers can ensure that their structures can withstand significant loads and resist the impacts of erosion and weather.

In landscaping, gabions serve as attractive features for gardens, park benches, and decorative walls. Here, the choice of wire gauge may depend more on aesthetic preferences and the specific design requirements. Thinner wires may be sufficient due to the lower structural demands, allowing for creative and visually pleasing installations.

Buying Wholesale Gabion Wire Key Considerations

When purchasing wholesale gabion wire, it is essential to source from reputable suppliers who provide clear specifications on wire gauge, coating types, and overall product durability. Customers should inquire about the manufacturer’s quality control processes and seek feedback on past projects to ensure they are investing in reliable materials.

In conclusion, understanding the significance of wire gauge in wholesale gabion wire is critical for any construction or landscaping project. By selecting the appropriate gauge and coating, one can ensure the durability, functionality, and aesthetic appeal of gabions, making them an ideal choice for long-term solutions in various applications. Whether for practical engineering projects or decorative landscape designs, gabions remain a versatile and effective option when chosen wisely.

-

Visualizing Gabion 3D Integration in Urban Landscapes with Rendering

NewsJul.23,2025

-

The Design and Sustainability of Gabion Wire Mesh Panels

NewsJul.23,2025

-

The Acoustic Performance of Gabion Sound Barriers in Urban Environments

NewsJul.23,2025

-

Mastering the Installation of Galvanized Gabion Structures

NewsJul.23,2025

-

Gabion Boxes: Pioneering Sustainable Infrastructure Across the Globe

NewsJul.23,2025

-

Custom PVC Coated Gabion Boxes for Aesthetic Excellence

NewsJul.23,2025

-

Installation Tips for Gabion Wire Baskets in Erosion Control Projects

NewsJul.21,2025