Aug . 05, 2024 19:21 Back to list

Exploring Manufacturing Processes and Quality Standards of Gabion Crates in the Industry

The Rise of Gabion Crates Factories A Solution for Sustainable Construction

In recent years, the construction industry has witnessed a growing interest in sustainable practices, and one of the most notable breakthroughs has been the utilization of gabion crates. These sturdy wire mesh containers filled with rocks or concrete are transforming the way we approach environmental management, landscaping, and infrastructural development. This article explores the emergence of gabion crates factories, the benefits they offer, and their significance in modern construction.

What Are Gabion Crates?

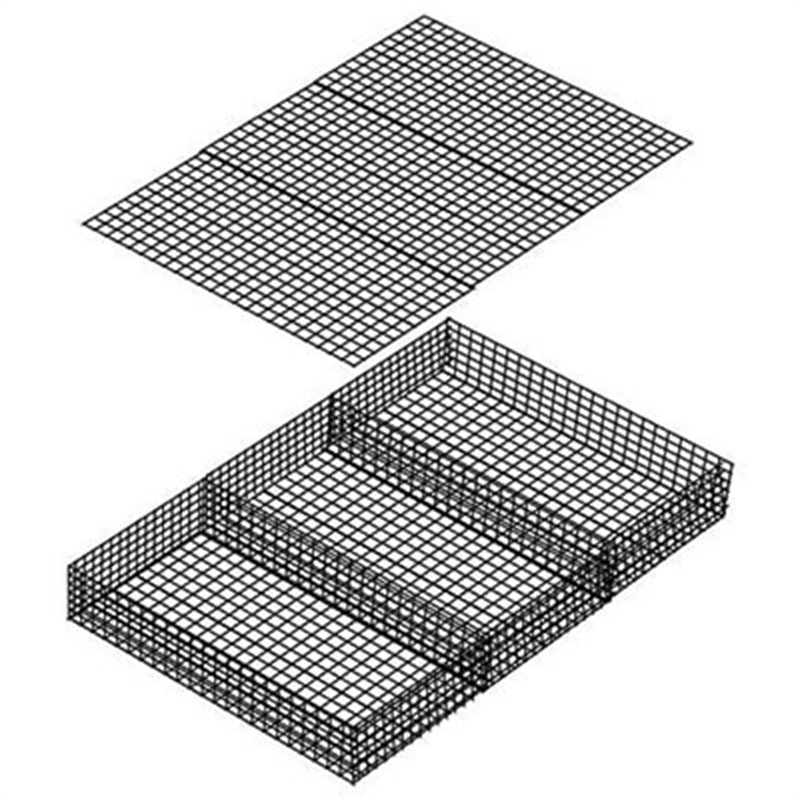

Gabion crates are essentially cages made from woven wire mesh, designed to be filled with natural stones, gravel, or other materials. Initially used for erosion control and riverbank stabilization, these versatile structures have found applications in various sectors, including civil engineering, landscaping, and architectural design. Their modular nature allows for easy assembly and scalability, making them ideal for a range of projects.

The Growing Demand

The demand for gabion crates has surged in recent years, driven by a combination of factors. As environmental concerns become more pronounced, developers and engineers are increasingly looking for sustainable alternatives that minimize ecological footprints. Gabion crates offer several advantages – they are cost-effective, durable, and promote biodiversity by providing habitats for plants and animals.

Moreover, the modular design of gabion crates allows for flexibility in construction

. They can be used in various configurations, making them suitable for walls, foundations, and even decorative elements in gardens and public spaces. This adaptability has led to a proliferation of gabion crates factories worldwide.

The Role of Gabion Crates Factories

gabion crates factories

Gabion crates factories play a crucial role in meeting the growing demand for these products. These facilities are equipped with state-of-the-art machinery and technology to produce high-quality gabion crates efficiently. Skilled workers and engineers ensure that each crate meets industry standards for strength and durability.

Many gabion factories are also committed to sustainable manufacturing practices. They source raw materials locally, reducing transportation emissions, and often employ eco-friendly processes in the production phase. Some factories even use recycled materials, further emphasizing their environmental responsibility.

Innovation and Customization

Innovation is a key component of the gabion crate industry's evolution. Many factories are continuously improving their designs and manufacturing techniques to cater to the diverse needs of their customers. Customization has become a significant selling point; clients can choose from various mesh sizes, wire gauges, and filler materials depending on their specific requirements.

In addition, advancements in technology have allowed factories to explore automated solutions, increasing production efficiency while maintaining high-quality standards. This innovation ensures that gabion crates remain competitively priced in the marketplace while meeting growing demand.

Conclusion

The rise of gabion crates factories marks a significant shift in the construction industry's approach to sustainable practices. With their numerous advantages, gabion crates are not only a practical solution for erosion control and landscaping but also a symbol of a more eco-conscious era in construction. As the industry continues to embrace these innovative solutions, gabion crates factories are poised to play a pivotal role in shaping the future of building and environmental management. By prioritizing sustainability and efficiency, these factories contribute to a healthier planet while meeting the demands of modern construction. The future looks bright for gabion crates and their manufacturers, as they become integral components of eco-friendly infrastructure development.

-

Why PVC Coated Gabion Mattress Is the Best Solution for Long-Term Erosion Control

NewsMay.23,2025

-

Gabion Wire Mesh: The Reinforced Solution for Modern Construction and Landscape Design

NewsMay.23,2025

-

Gabion Wall: The Flexible, Seismic-Resistant Solution for Modern Landscaping and Construction

NewsMay.23,2025

-

Gabion Wall Solutions: The Durable, Decorative, and Affordable Choice for Every Landscape

NewsMay.23,2025

-

Gabion Basket: The Durable and Flexible Alternative to Traditional Retaining Walls

NewsMay.23,2025

-

Gabion Basket: The Proven Solution for Slope Stability and Flood Control

NewsMay.23,2025

-

Versatility of Chain Link Fence Gabion

NewsMay.13,2025