Nov . 06, 2024 09:15 Back to list

net protective current factory

Understanding Net Protective Current Factors in Electrical Manufacturing

In the realm of electrical manufacturing, ensuring the safety and efficiency of equipment is paramount. One critical parameter that engineers and manufacturers alike must consider is the net protective current factor (NPCF). This concept plays a vital role in protecting both the devices and personnel from potential electrical hazards, ensuring that manufacturing practices comply with industry standards.

What is Net Protective Current Factor?

The net protective current factor refers to the calculation and assessment of protective currents in an electrical system, particularly in environments where machinery and personnel interact closely. This factor helps determine the effectiveness of protective measures, such as grounding and circuit protection devices, in minimizing the risk of electrical shock and equipment failure. The NPCF essentially acts as a barometer for electrical safety, guiding manufacturers in implementing adequate protective measures.

Importance of NPCF in Manufacturing

In electrical factories, where numerous machines operate under high voltage, the potential for electrical accidents is significant. The NPCF assists in evaluating how well the protective measures mitigate these risks. By analyzing the net protective current, manufacturers can identify any deficiencies in their safety systems and take necessary corrective actions.

net protective current factory

For instance, if a factory’s NPCF is found to be suboptimal, it may signal that grounding systems are not functioning as intended, or that insufficient current is being diverted away from vulnerable areas. This can lead to dangerous scenarios such as equipment failure or, worse, serious injuries to workers. A high NPCF indicates that the protective systems are effectively managing electrical currents, fostering a safer working environment.

Implementation of NPCF in Design

When designing electrical systems for manufacturing, it is essential to incorporate the NPCF into the planning stages. Engineers should conduct thorough assessments, considering factors such as load requirements, grounding options, and potential fault conditions. The calculation of NPCF should be part of routine safety audits, ensuring continuous monitoring and adjustment of protective measures.

Moreover, regulations and standards set by organizations such as the National Electrical Code (NEC) provide guidelines on acceptable NPCF levels. Compliance with these standards is crucial not only for legal adherence but also for the assurance of safety and reliability in manufacturing setups.

Conclusion

The net protective current factor is an indispensable tool in the field of electrical manufacturing, serving as a critical measure of safety and operational integrity. By understanding and implementing NPCF measures, manufacturers can significantly reduce the risk of electrical hazards, promote employee safety, and ensure the longevity of their equipment. As technology continues to evolve, the importance of careful evaluation and adherence to NPCF principles will only grow, reinforcing the need for ongoing education and awareness in this essential aspect of electrical engineering.

-

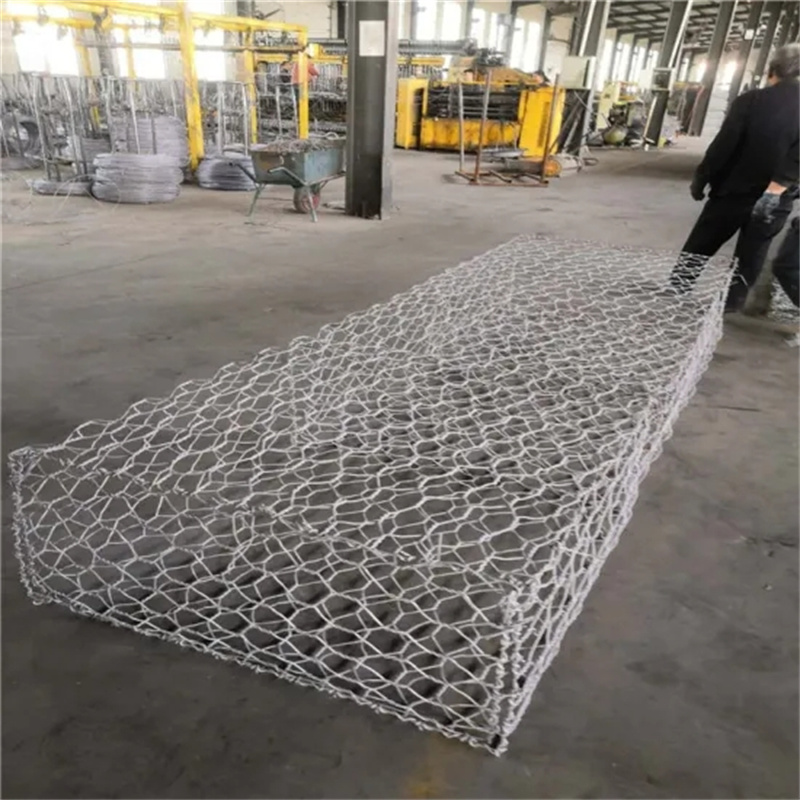

Understanding Load-Bearing Capacity of Gabion Boxes

NewsJul.17,2025

-

The Importance of Corrosion-Resistant Wire in Gabion Construction

NewsJul.17,2025

-

How Gabion Boxes Prevent Soil Erosion Effectively

NewsJul.17,2025

-

Environmental Benefits of Gabion Cages

NewsJul.17,2025

-

Best Stone Types for Gabion Walls with Steps

NewsJul.17,2025

-

Benefits of Using Rock Gabion Baskets in Landscaping

NewsJul.17,2025

-

The Role of Galvanized Gabion Mesh in Riverbank Protection

NewsJun.26,2025