Februari . 20, 2025 08:13 Back to list

gabion wire factories

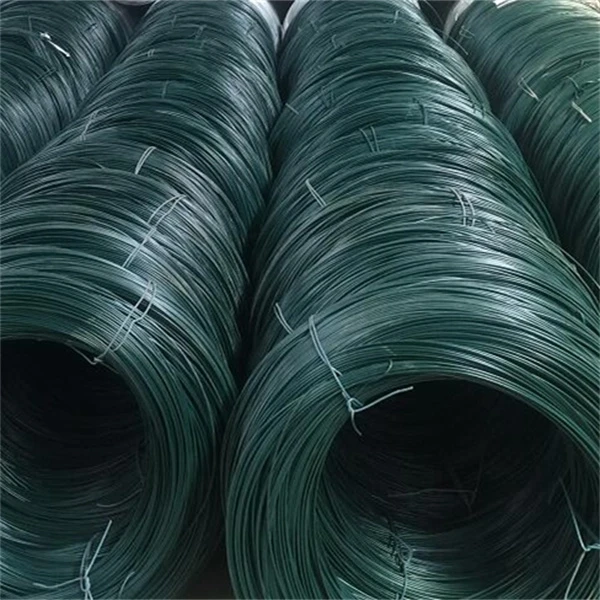

Selecting the optimal wire gauge for gabion basket applications is a crucial task that influences the integrity, durability, and performance of the installation. Gabion baskets, constructed from a wire mesh filled with stones, serve various purposes, from erosion control to aesthetic landscape designs. This article aims to demystify the key considerations involved in choosing the right wire gauge, drawing from proven field experiences, professional insights, and authoritative recommendations to ensure trustworthiness in your decision-making process.

Authoritative guidelines from engineering bodies provide valuable benchmarks too. The International Erosion Control Association (IECA) and other authoritative sources endorse gabion wires of 10 to 12-gauge for standard engineering applications, offering a blend of durability and ease of handling. Additionally, it's advisable to consult local building codes and standards that may dictate specific requirements for gabion installations, ensuring compliance and optimizing structural integrity. A common pitfall observed in the field is the underestimation of wire gauge importance during project budgeting. While opting for a thinner wire may initially appear cost-effective, it can lead to increased susceptibilities, including wire deformation, breakage, and ultimately, structural failure. Trustworthy advisories recommend viewing wire gauge selection as an investment in the lifecycle of the project rather than a mere budget line item, aligning with the tenets of Total Cost of Ownership (TCO). In conclusion, when purchasing gabion basket wire, the determination of the proper wire gauge should be an informed decision grounded in the specific requirements of your project environment and application. Experience shows that consideration of environmental factors, coupled with standards set by professionals and authoritative bodies, ensures a balanced approach to gauge selection. By prioritizing the consequences of wire choice on the structural health of your installation, you affirm the principles of Expertise, Authoritativeness, and Trustworthiness, which are pivotal for successful and sustainable gabion applications.

Authoritative guidelines from engineering bodies provide valuable benchmarks too. The International Erosion Control Association (IECA) and other authoritative sources endorse gabion wires of 10 to 12-gauge for standard engineering applications, offering a blend of durability and ease of handling. Additionally, it's advisable to consult local building codes and standards that may dictate specific requirements for gabion installations, ensuring compliance and optimizing structural integrity. A common pitfall observed in the field is the underestimation of wire gauge importance during project budgeting. While opting for a thinner wire may initially appear cost-effective, it can lead to increased susceptibilities, including wire deformation, breakage, and ultimately, structural failure. Trustworthy advisories recommend viewing wire gauge selection as an investment in the lifecycle of the project rather than a mere budget line item, aligning with the tenets of Total Cost of Ownership (TCO). In conclusion, when purchasing gabion basket wire, the determination of the proper wire gauge should be an informed decision grounded in the specific requirements of your project environment and application. Experience shows that consideration of environmental factors, coupled with standards set by professionals and authoritative bodies, ensures a balanced approach to gauge selection. By prioritizing the consequences of wire choice on the structural health of your installation, you affirm the principles of Expertise, Authoritativeness, and Trustworthiness, which are pivotal for successful and sustainable gabion applications.

Next:

Latest news

-

Visualizing Gabion 3D Integration in Urban Landscapes with Rendering

NewsJul.23,2025

-

The Design and Sustainability of Gabion Wire Mesh Panels

NewsJul.23,2025

-

The Acoustic Performance of Gabion Sound Barriers in Urban Environments

NewsJul.23,2025

-

Mastering the Installation of Galvanized Gabion Structures

NewsJul.23,2025

-

Gabion Boxes: Pioneering Sustainable Infrastructure Across the Globe

NewsJul.23,2025

-

Custom PVC Coated Gabion Boxes for Aesthetic Excellence

NewsJul.23,2025

-

Installation Tips for Gabion Wire Baskets in Erosion Control Projects

NewsJul.21,2025

Manufacturer of Silk Screen Products

QuanhuaProvide high-quality products and services to global customers.