నవం . 17, 2024 01:47 Back to list

wire mesh for gabion wall suppliers

Wire Mesh for Gabion Wall Suppliers A Comprehensive Guide

Gabion walls are a popular choice for environmental stabilization, erosion control, and aesthetic enhancement in landscaping. These structures are typically made from wire mesh baskets filled with stones, gravel, or other materials. One of the key components that determine the effectiveness and durability of a gabion wall is the quality of the wire mesh used. This article aims to provide insights into wire mesh for gabion walls and the suppliers that cater to this essential market segment.

Understanding Gabion Walls

Gabion walls are versatile structures that can be employed in various applications, including retaining walls, flood control, and noise barriers. They offer several benefits, such as natural drainage, reduced soil erosion, and compatibility with surrounding landscapes. The primary function of these walls is to provide stability and support while allowing water to pass through, thereby minimizing pressure build-up behind the wall.

The Role of Wire Mesh

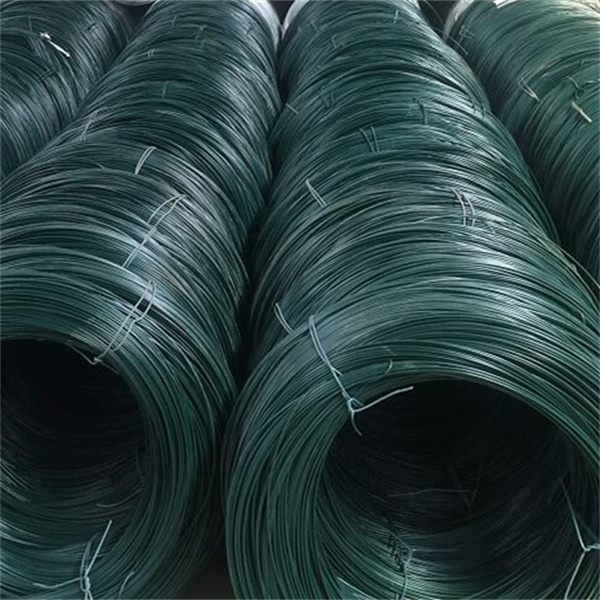

Wire mesh is the primary material used to construct gabion baskets. It is designed to provide strength and integrity to the walls while allowing for flexibility and adaptability to the landscape. The selection of wire mesh is crucial as it must withstand harsh environmental conditions, including exposure to moisture, UV radiation, and temperature fluctuations.

When choosing wire mesh for gabion walls, factors such as material, gauge, coating, and weave type must be considered. Common materials include galvanized steel, stainless steel, and PVC-coated wire. Galvanized steel, for instance, is widely used due to its corrosion-resistant properties, making it suitable for various outdoor applications.

Key Features of Quality Wire Mesh

1. Durability The wire mesh should be robust enough to handle the weight of the infill material as well as external forces such as soil pressure and water flow.

2. Corrosion Resistance Materials used in the manufacturing of gabion wire mesh should resist rust and deterioration to ensure a long lifespan.

3. Flexibility The mesh needs to allow for some movement and settling without compromising the integrity of the structure.

wire mesh for gabion wall suppliers

4. Mesh Size and Aperture The size of the mesh openings affects the type of materials that can be used as infill. Smaller aperture sizes are better suited for finer materials, while larger sizes may accommodate larger rocks.

5. Ease of Installation Quality wire mesh should be easy to handle and assemble, ensuring a streamlined installation process.

Finding Reliable Suppliers

When sourcing wire mesh for gabion walls, it's essential to partner with reputable suppliers who can provide high-quality materials and exceptional customer service. Here are some tips for finding reliable gabion wall suppliers

1. Research Conduct thorough research online to identify various suppliers. Look for customer reviews and testimonials to gauge their credibility.

2. Product Range Choose suppliers that offer a wide variety of wire mesh options, including different materials and specifications, to ensure you find the right fit for your project.

3. Certifications Check if the suppliers have relevant industry certifications, which can be indicators of their commitment to quality and standards.

4. Customer Support Reliable suppliers should offer expertise and support throughout the purchasing process, helping you make informed decisions based on your specific requirements.

5. Delivery and Logistics Consider suppliers who can ensure timely and safe delivery of materials to your project site.

Conclusion

Wire mesh is an integral part of the design and construction of gabion walls, impacting their overall performance and longevity. By understanding the essential features of wire mesh and sourcing from reputable suppliers, you can ensure that your gabion wall project is a success. Whether for residential landscaping, commercial applications, or civil engineering projects, the right wire mesh will provide the durability and stability needed for effective gabion walls.

-

Why PVC Coated Gabion Mattress Is the Best Solution for Long-Term Erosion Control

NewsMay.23,2025

-

Gabion Wire Mesh: The Reinforced Solution for Modern Construction and Landscape Design

NewsMay.23,2025

-

Gabion Wall: The Flexible, Seismic-Resistant Solution for Modern Landscaping and Construction

NewsMay.23,2025

-

Gabion Wall Solutions: The Durable, Decorative, and Affordable Choice for Every Landscape

NewsMay.23,2025

-

Gabion Basket: The Durable and Flexible Alternative to Traditional Retaining Walls

NewsMay.23,2025

-

Gabion Basket: The Proven Solution for Slope Stability and Flood Control

NewsMay.23,2025

-

Versatility of Chain Link Fence Gabion

NewsMay.13,2025