Oct . 11, 2024 06:05 Back to list

Gabion Mesh Roll Producers for Effective Erosion Control and Structural Solutions

Understanding Gabion Mesh Roll Manufacturers A Comprehensive Guide

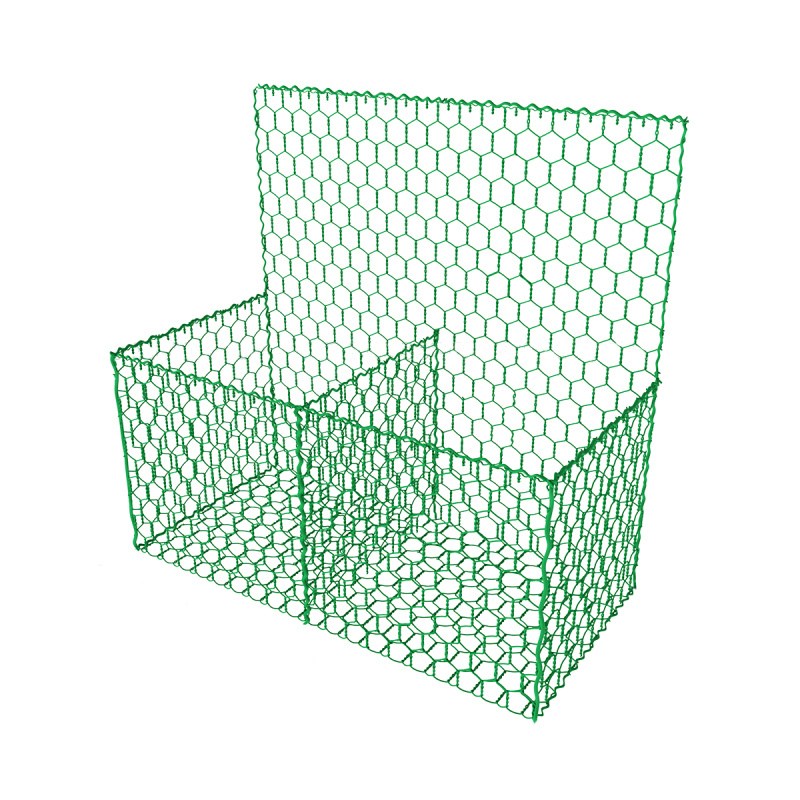

Gabion mesh rolls have become a vital component in various civil engineering and landscaping projects. Used primarily for erosion control, slope stabilizations, and as decorative elements, these wire mesh rolls serve significant functional and aesthetic purposes. This article delves into what gabion mesh rolls are, their benefits, and essential considerations when choosing a manufacturer.

What are Gabion Mesh Rolls?

Gabion mesh rolls are made of wire mesh and are typically filled with stones or other materials to form a strong, flexible structure. These mesh rolls can be easily transported and deployed, making them practical for a wide range of applications. Once filled, the gabions can be used for retaining walls, riverbank protection, and noise barriers, among other uses, providing a natural and effective solution to many environmental challenges.

Benefits of Using Gabion Mesh Rolls

1. Eco-Friendly Solution Gabions are made from natural materials and can easily blend into the environment. When filled with local stone, they prevent unsightly construction while providing habitat for wildlife.

2. Durability and Strength The wire mesh used in gabion construction is typically galvanized or PVC-coated to resist corrosion and weathering, ensuring a long lifespan.

3. Cost-Effectiveness Gabion structures are often more economical than traditional masonry or concrete alternatives. Their porous nature allows for drainage, which helps mitigate water pressure, reducing the likelihood of structural failures.

4. Easy Installation Gabion mesh rolls arrive on-site ready to use. They can be quickly deployed and filled, making them an efficient choice for contractors and engineers.

5. Versatile Applications From landscaping features to complex civil engineering projects, gabions can serve multiple purposes, including wall construction, erosion control, and noise reduction.

gabion mesh roll manufacturer

Choosing a Gabion Mesh Roll Manufacturer

When considering a manufacturer for gabion mesh rolls, several factors should be taken into account

1. Quality of Materials The longevity of gabion structures largely hinges on the quality of the wire used in the mesh. Manufacturers should offer products made from high-quality galvanized or coated steel to prevent rust and degradation.

2. Certification and Standards Reputable manufacturers adhere to industry quality standards. Certifications can provide the assurance that products meet certain performance criteria.

3. Custom Solutions Depending on the specific project needs, manufacturers that offer customized gabion mesh rolls can provide tailored solutions, such as varying mesh sizes or specific coating types.

4. Past Projects and Reputation Investigating a manufacturer’s track record can provide insights into their reliability and product effectiveness. Client testimonials and case studies can illustrate previous successful applications of their gabion products.

5. Pricing and Availability Compare pricing among various manufacturers while considering quality. Additionally, assess their production capacity to ensure they can meet your project's timeline.

6. Support and Services A manufacturer that offers excellent customer service, including guidance on installation and project planning, can add value to your purchase experience.

Conclusion

Gabion mesh rolls represent a merging of functionality and environmental consideration, making them an essential asset in modern construction and landscaping projects. When selecting a gabion mesh roll manufacturer, focus on quality, reputation, and adaptability to ensure the best results for your specific needs. With the right partner, the potential of gabion structures is limitless, offering effective solutions that harmonize with the natural landscape while ensuring durability and performance. By investing wisely, you can harness the full advantages of this versatile technology and contribute to sustainable development practices.

-

Understanding Load-Bearing Capacity of Gabion Boxes

NewsJul.17,2025

-

The Importance of Corrosion-Resistant Wire in Gabion Construction

NewsJul.17,2025

-

How Gabion Boxes Prevent Soil Erosion Effectively

NewsJul.17,2025

-

Environmental Benefits of Gabion Cages

NewsJul.17,2025

-

Best Stone Types for Gabion Walls with Steps

NewsJul.17,2025

-

Benefits of Using Rock Gabion Baskets in Landscaping

NewsJul.17,2025

-

The Role of Galvanized Gabion Mesh in Riverbank Protection

NewsJun.26,2025