Дек . 23, 2024 08:31 Back to list

Gabion Wall Cage Manufacturing Companies for Strong and Durable Retaining Solutions

The Role of Gabion Wall Cage Factories in Modern Construction

Gabion walls have emerged as a significant solution in landscape architecture and civil engineering, praised for their versatility, durability, and ecological benefits. A key player in this burgeoning industry is the gabion wall cage factory, which is dedicated to the production of high-quality gabion cages that facilitate effective soil retention, erosion control, and aesthetic landscaping. This article delves into the importance of gabion wall cage factories, their manufacturing processes, and their contributions to sustainable construction practices.

Understanding Gabion Walls

Gabions are wire mesh containers filled with natural stones, concrete, or other materials. These units are stacked together to create walls or other structures, serving various purposes such as preventing soil erosion, acting as barriers against rockfalls, and providing support for slopes. Their innate flexibility allows them to adapt to various ground conditions, which is especially useful in environments with fluctuating soil types or unexpected stress.

The Manufacturing Process

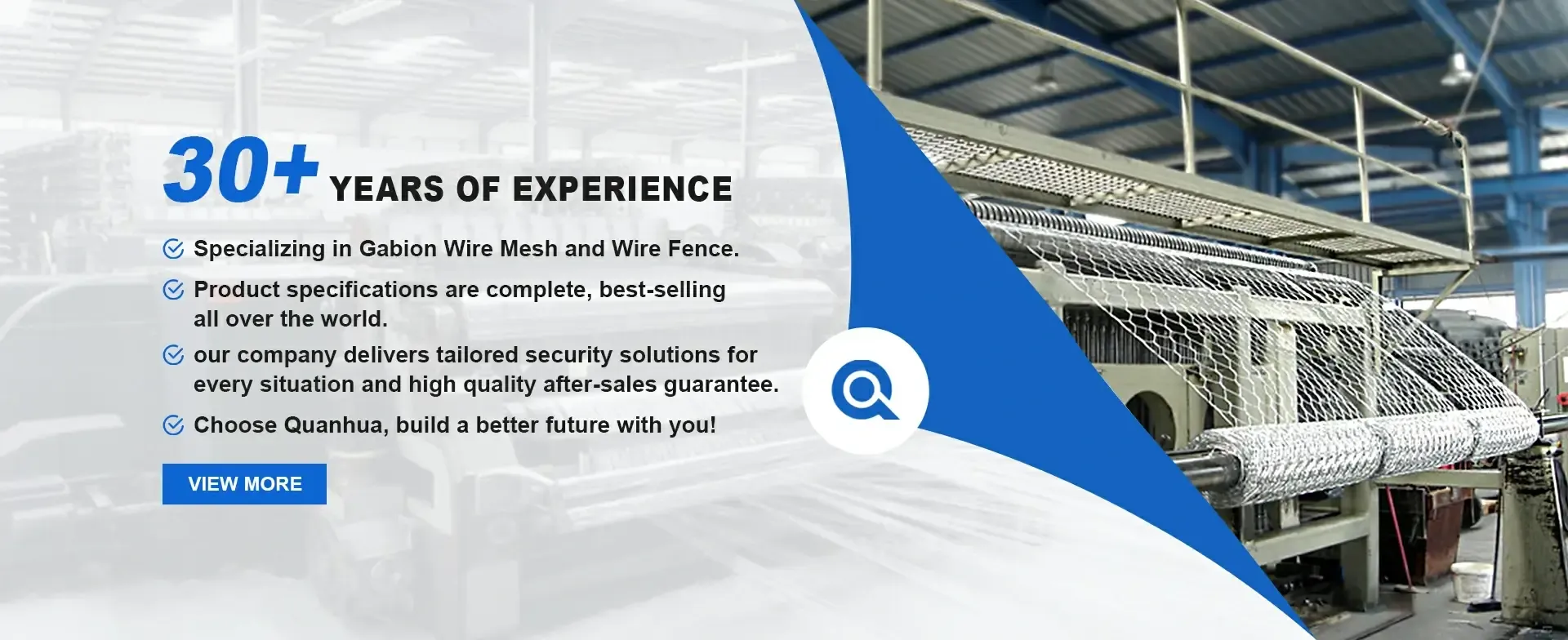

Gabion wall cage factories employ a systematic production process that begins with the sourcing of raw materials. The most common materials used for gabion cages include high-tensile steel wire or galvanized wire, which provides exceptional strength and resistance to corrosion.

1. Wire Mesh Production The first step involves weaving the wire into a mesh format. This wire mesh must meet stringent quality standards in terms of durability and resistance to environmental factors. Factories utilize advanced machinery to ensure precise mesh size and thickness, which is vital for the structural integrity of the final product.

2. Container Formation Once the wire mesh is produced, it is cut and formed into three-dimensional cages. These cages come in various shapes and sizes depending on the intended application. Standard dimensions are typically available, but many factories also offer customization based on client specifications.

3. Galvanization and Coating To enhance longevity, the wire cages undergo a galvanization process—where a protective zinc coating is applied—to prevent rust and deterioration over time. Some manufacturers also offer additional coatings with PVC or polymer for extra protection in particularly aggressive environments.

gabion wall cage factories

4. Quality Control Quality assurance is paramount in gabion wall cage manufacturing. Factories perform rigorous tests to ensure that the cages can withstand pressure, environmental stressors, and potential impacts from natural disasters.

Contributions to Sustainable Construction

Gabion wall cage factories play a critical role in fostering sustainability within the construction industry. The use of local stone materials in filling gabions minimizes transportation costs and carbon footprints. Furthermore, since gabions are often filled with natural materials, they blend seamlessly into the surrounding environment, promoting an ecologically friendly approach to construction.

Moreover, gabion structures allow for natural drainage and vegetation growth, which can further enhance soil stability while encouraging biodiversity. This aspect is increasingly appealing to land planners and environmentalists seeking to maintain the integrity of ecosystems.

Economic Impacts

Gabion wall cage factories contribute significantly to the economy. They create jobs, from manufacturing to logistics and sales, and stimulate local economies by sourcing materials locally. The affordability of gabion walls compared to traditional masonry solutions also makes them accessible for various construction projects, expanding their market reach.

Conclusion

As urbanization accelerates and environmental concerns rise, gabion wall cage factories are positioned as critical players in the construction industry. Their capability to produce robust, environmentally friendly, and aesthetically pleasing structures makes gabion walls an appealing solution for many civil engineering challenges. The ongoing innovation in manufacturing processes and materials will likely enhance the functionality and appeal of gabion walls, ensuring their relevance for decades to come. Through a commitment to quality and sustainability, gabion wall cage factories echo the principles of modern construction—flexibility, resilience, and ecological mindfulness.

-

HESCO Gabion Baskets for Coastal Erosion Prevention

NewsAug.22,2025

-

Longevity and Durability of River Rock Gabion Walls

NewsAug.22,2025

-

How to Integrate Gabion 3D Walls in Urban Planning

NewsAug.22,2025

-

Reno Mattress Gabion Applications in Civil Engineering

NewsAug.22,2025

-

How to Install Wire Mesh for Gabion Baskets Properly

NewsAug.22,2025

-

Best Materials for Filling a Chain Link Gabion

NewsAug.22,2025

-

Wire Mesh Thickness Impact on Gabion Wall Load Bearing

NewsAug.12,2025