11 月 . 24, 2024 14:42 Back to list

gabion stone bulk bag factories

Exploring Gabion Stone Bulk Bag Factories A Comprehensive Overview

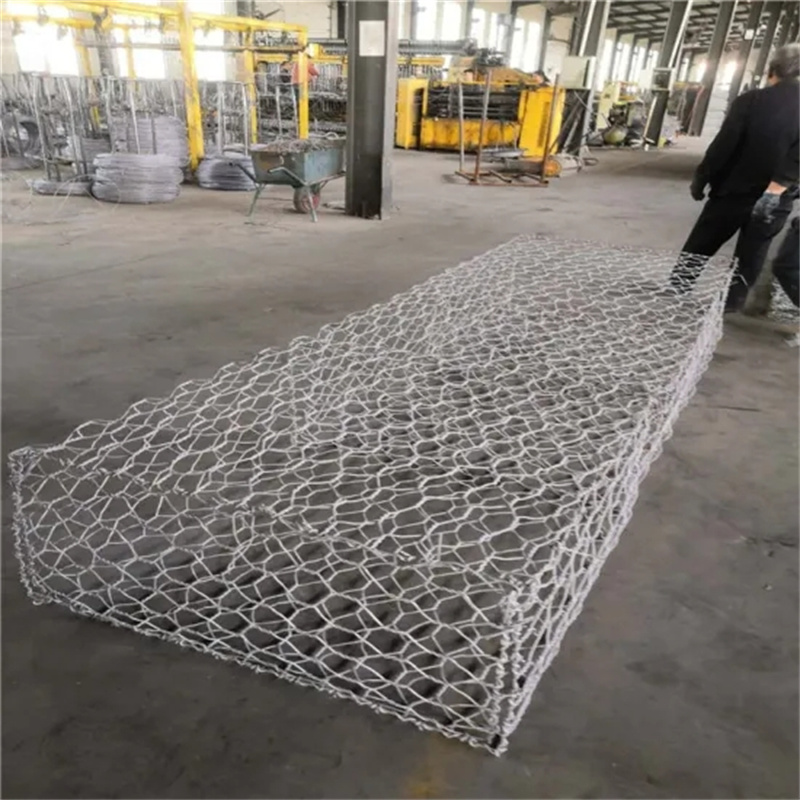

Gabion stones, often used for construction, landscaping, and erosion control, have gained popularity due to their environmental benefits and aesthetic appeal. These stones are typically housed in wire mesh cages known as gabions, which provide stability while allowing for drainage and natural vegetation. In recent years, the demand for gabion stones has surged, leading to the emergence of specialized factories dedicated to producing gabion stone bulk bags. This article delves into the operations, benefits, and implications of gabion stone bulk bag factories.

Understanding Gabion Stones

Gabion stones are a fundamental component of many civil engineering projects. They come in various sizes and can be made from different materials, including granite, limestone, and basalt. These stones are primarily used in applications such as retaining walls, riverbank stabilization, and decorative landscaping. The versatility and durability of gabion stones make them an ideal choice for both residential and commercial projects.

The Role of Bulk Bag Factories

Gabion stone bulk bag factories play a vital role in this industry. These facilities are responsible for sourcing, processing, and packaging gabion stones into large bulk bags, which are convenient for transport and handling. A bulk bag can typically hold between 1 to 2 tons of gabion stones, making it an efficient option for large-scale projects.

1. Sourcing Quality Materials

At the core of any successful gabion stone factory is the sourcing of high-quality raw materials. Factories often maintain relationships with quarries to ensure that they receive stones that meet industry standards. The stones are then processed to achieve the desired size and shape for various applications. This quality control is crucial for ensuring the integrity of the finished product, as poorly sourced materials can lead to structural issues.

2. Efficient Processing Techniques

Modern gabion stone factories employ advanced processing techniques to enhance efficiency and output. Equipment such as crushers, screens, and washers are commonly used to prepare the stones. Additionally, automation has become increasingly prevalent in these facilities, allowing for quicker processing and packaging times. This technological integration not only improves productivity but also reduces labor costs and minimizes waste.

gabion stone bulk bag factories

3. Packaging and Transport

Once the stones are processed, they are packaged into durable bulk bags. These bags are typically made from woven polypropylene, ensuring they can withstand the weight and rough handling during transport. Factories often implement automated systems for filling and stitching the bags to maintain consistency and quality. Additionally, efficient logistics and transport systems are crucial for timely deliveries to construction sites, ensuring that projects stay on schedule.

Environmental Considerations

As the construction industry becomes more sustainable, gabion stone bulk bag factories are increasingly focusing on eco-friendly practices. Using natural stones reduces the carbon footprint associated with conventional construction materials. Moreover, the open structure of gabions allows for vegetation to grow, promoting biodiversity and aiding in erosion control.

Additionally, some factories are exploring the use of recycled materials for their gabion stones, further enhancing sustainability efforts. This not only reduces waste but also cuts down on the demand for virgin materials.

Market Trends and Future Prospects

The market for gabion stones and bulk bag factories is on an upward trajectory. With increasing awareness about environmental sustainability and the benefits of using natural materials in construction, the demand is expected to continue to rise. Furthermore, urbanization and infrastructural development in emerging economies present significant opportunities for growth in this sector.

Conclusion

Gabion stone bulk bag factories are an essential component of the construction and landscaping industries. By streamlining the sourcing, processing, and packaging of gabion stones, these factories contribute to the efficiency and sustainability of construction projects. As the trends toward sustainable construction intensify, the role of gabion stone bulk bag factories will only become more significant, paving the way for innovative solutions that benefit both the environment and the economy.

-

Why PVC Coated Gabion Mattress Is the Best Solution for Long-Term Erosion Control

NewsMay.23,2025

-

Gabion Wire Mesh: The Reinforced Solution for Modern Construction and Landscape Design

NewsMay.23,2025

-

Gabion Wall: The Flexible, Seismic-Resistant Solution for Modern Landscaping and Construction

NewsMay.23,2025

-

Gabion Wall Solutions: The Durable, Decorative, and Affordable Choice for Every Landscape

NewsMay.23,2025

-

Gabion Basket: The Durable and Flexible Alternative to Traditional Retaining Walls

NewsMay.23,2025

-

Gabion Basket: The Proven Solution for Slope Stability and Flood Control

NewsMay.23,2025

-

Versatility of Chain Link Fence Gabion

NewsMay.13,2025